Device and method for recovering high-temperature sensible heat of liquid blast furnace slag

A blast furnace slag and high temperature technology, which is applied in the field of devices for recovering high temperature sensible heat of liquid blast furnace slag, can solve the problems of thermal energy quality degradation, large water consumption, and inability to effectively recycle heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

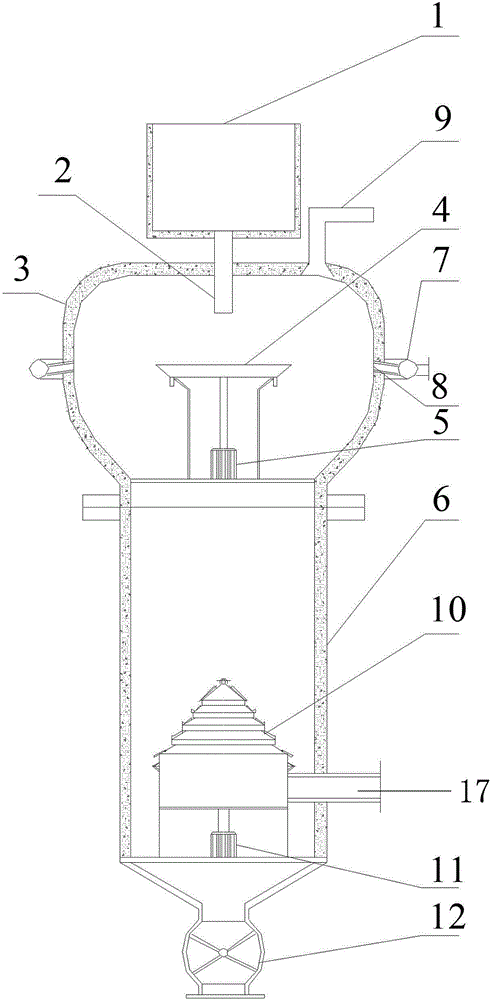

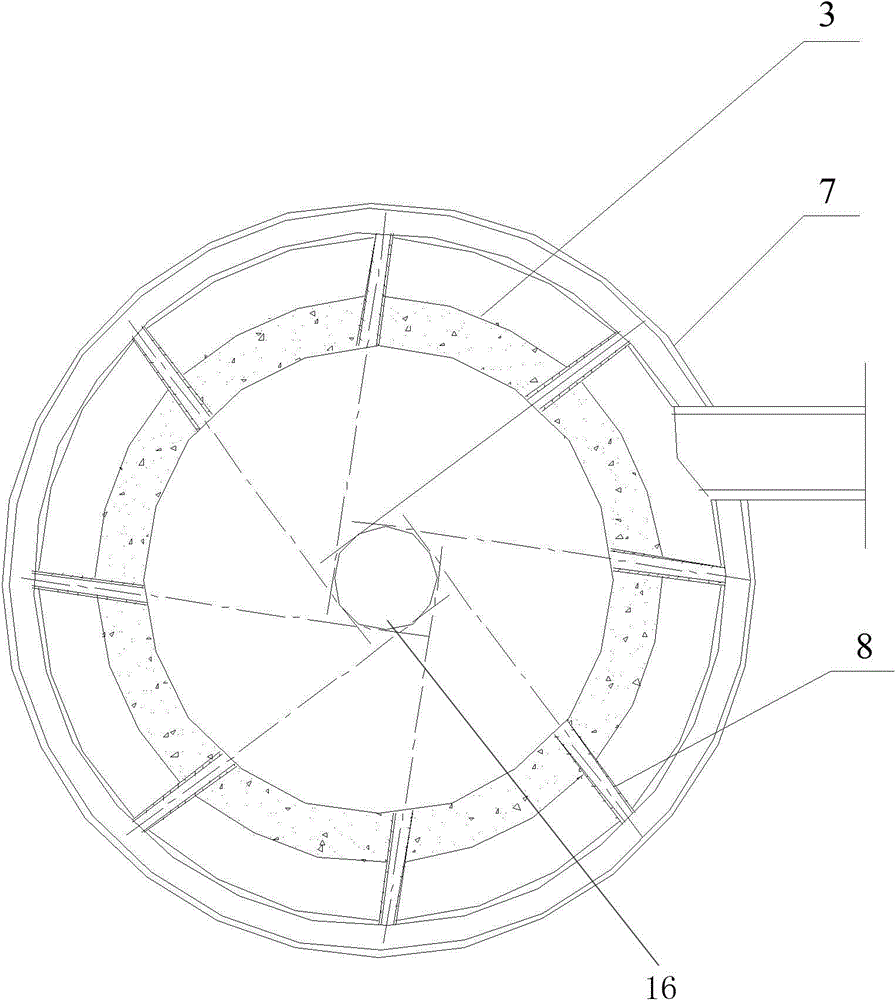

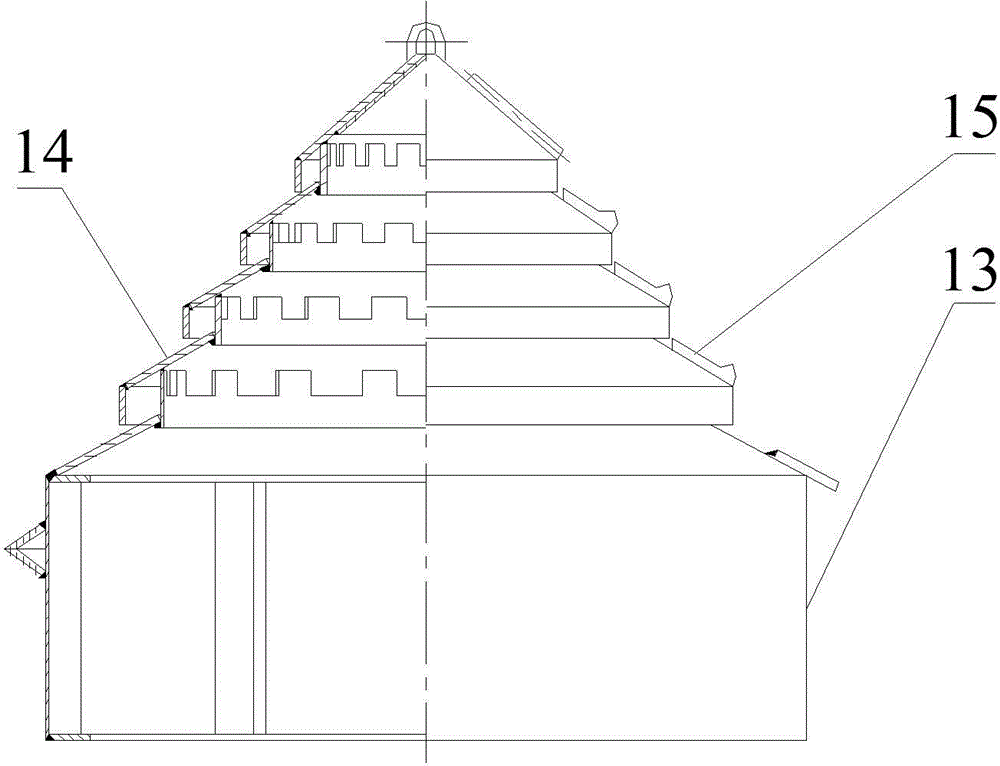

[0030]The invention proposes a device for recovering high-temperature sensible heat of liquid blast furnace slag, which is characterized in that: figure 1 As shown in , the device mainly includes tundish 1, slag flow pipe 2, granulation reactor 3, rotor 4, frequency conversion speed regulation motor 5, granulated slag packed bed 6, ring pipe 7, nozzle 8, gas outlet 9 , a rotary air distributor 10, a motor 11, and a rotary discharge valve 12; the top of the granulation reactor 3 is provided with a liquid blast furnace slag inlet (slag flow pipe 2) and a gas outlet 9, and above the slag flow pipe 2 is a tundish 1 , the inside of the granulation reactor 3 is equipped with a rotor 4 and a frequency conversion motor 5 for driving the rotor 4, and 6~8 nozzles 8 are arranged on the walls of the granulation reactor 3, and the nozzles 8 and the ring pipe 7 connected; the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com