Automatically cleaning apparatus of converter oxygen lance bonded slag

A converter oxygen lance and automatic cleaning technology, applied in the direction of manufacturing converters and improving process efficiency, can solve the problems of high labor intensity, large pieces of steel slag falling off, burns, etc., and achieve the effect of reasonable design and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

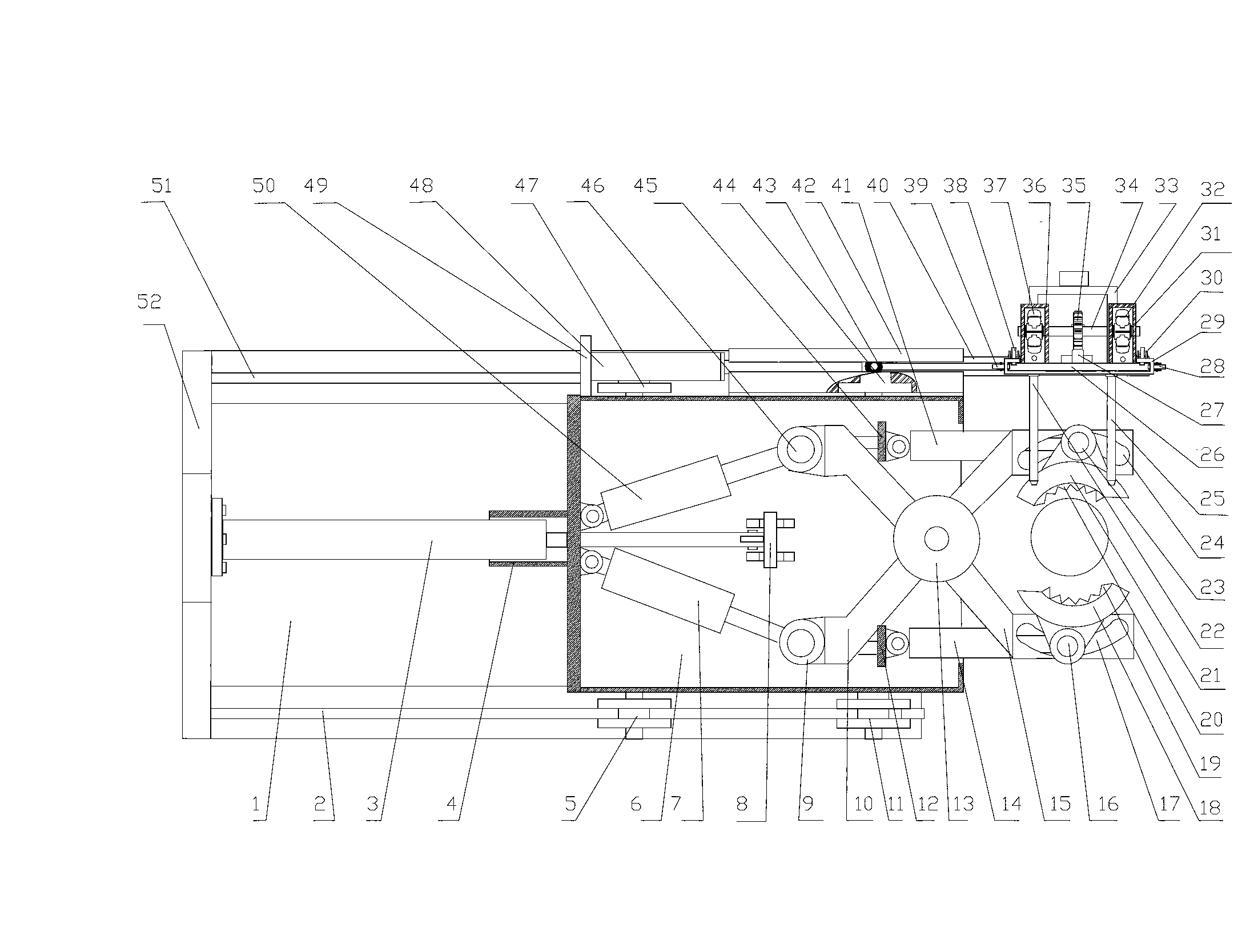

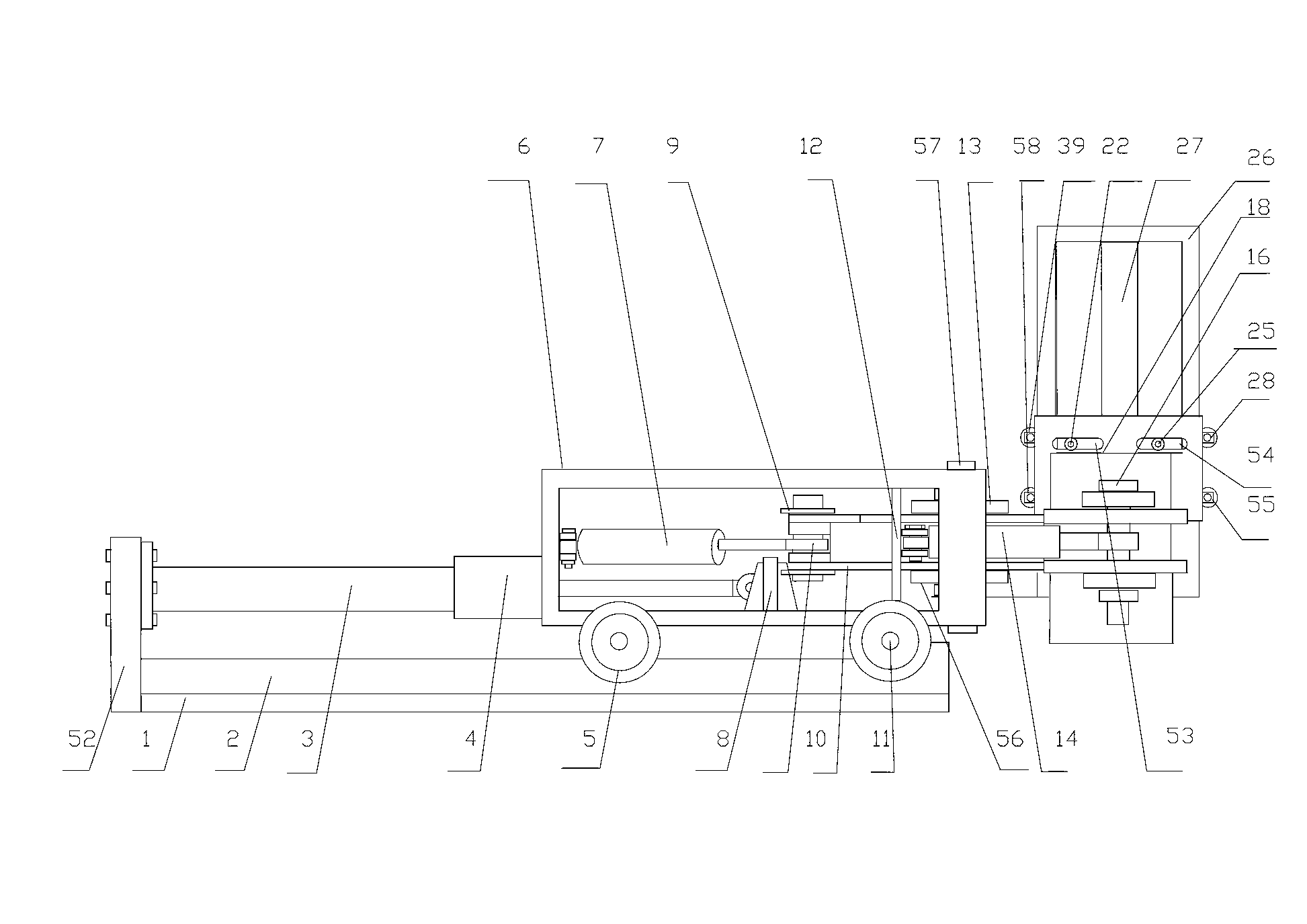

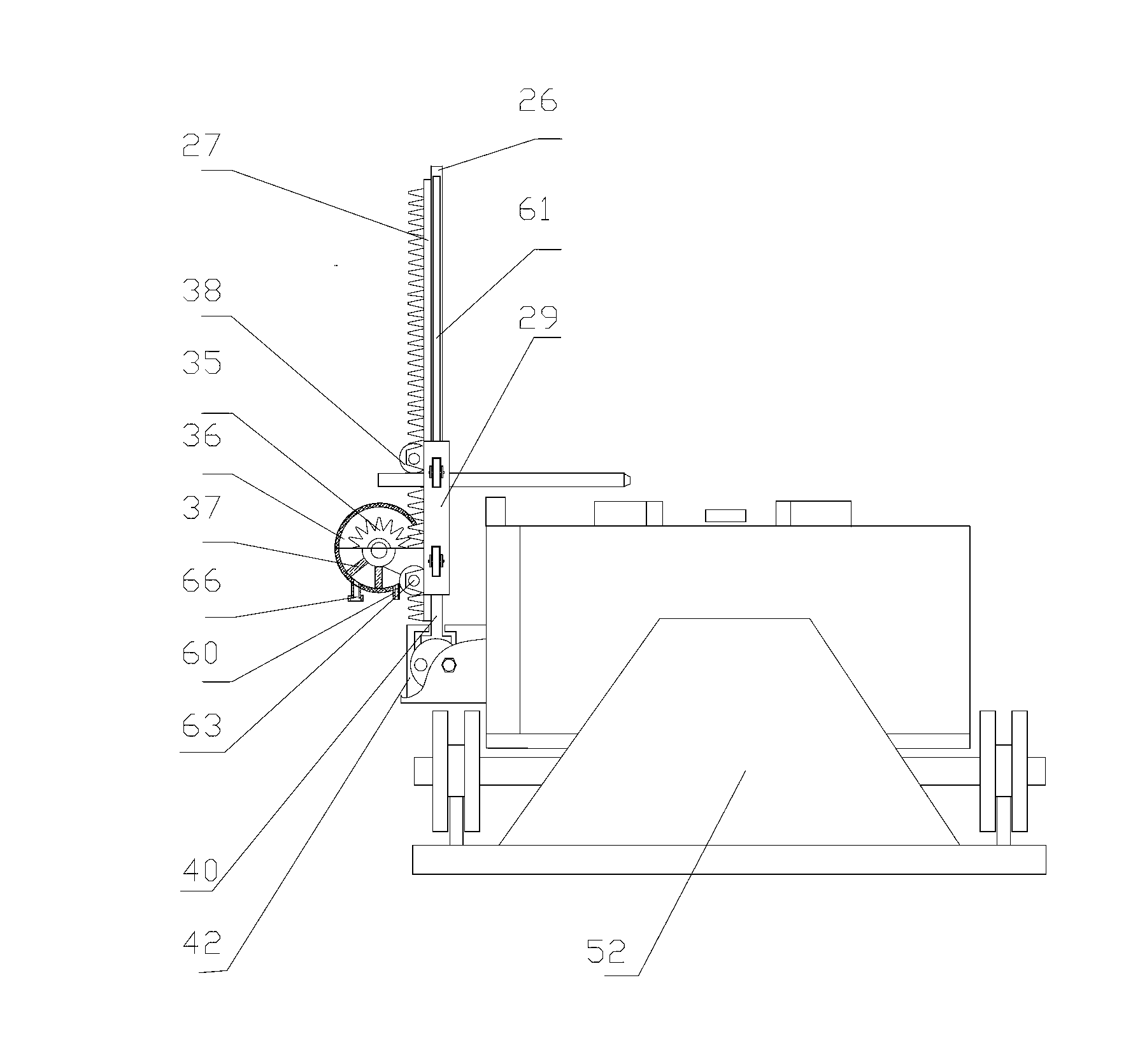

[0015] Such as figure 1 , 2, 3, and 4, it includes the base structure plate (1) and the track (2) on the base structure plate (1), the other side track (51), the rear vertical plate (52), the rear vertical plate (52 ) center right side is equipped with a push cylinder (3); on the track (2) and the other side track (51) is placed a mobile trolley (6); the two sides of the mobile trolley (6) are provided with a side left wheel ( 5), the right wheel on one side (11), the left wheel on the other side (47), the right wheel on the other side (44); the left wheel on one side (5) and the right wheel on one side (11) are placed on the side track (2 ), the left wheel (47) on the other side and the right wheel (44) on the other side are placed on the track (51) on the other side; the right end of the push cylinder (3) is connected to the trolley push plate ( 8), the trolley pushing plate (8) is fixed at the center of the bottom plate of the mobile trolley (6); the upper center of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com