5182 aluminum alloy tab stock substrate and production method thereof

A production method and aluminum alloy technology, which is applied in the field of aluminum alloy manufacturing, can solve problems such as increasing operating time and reducing yield, and achieves the effects of increasing yield, improving efficiency, and preventing fire accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

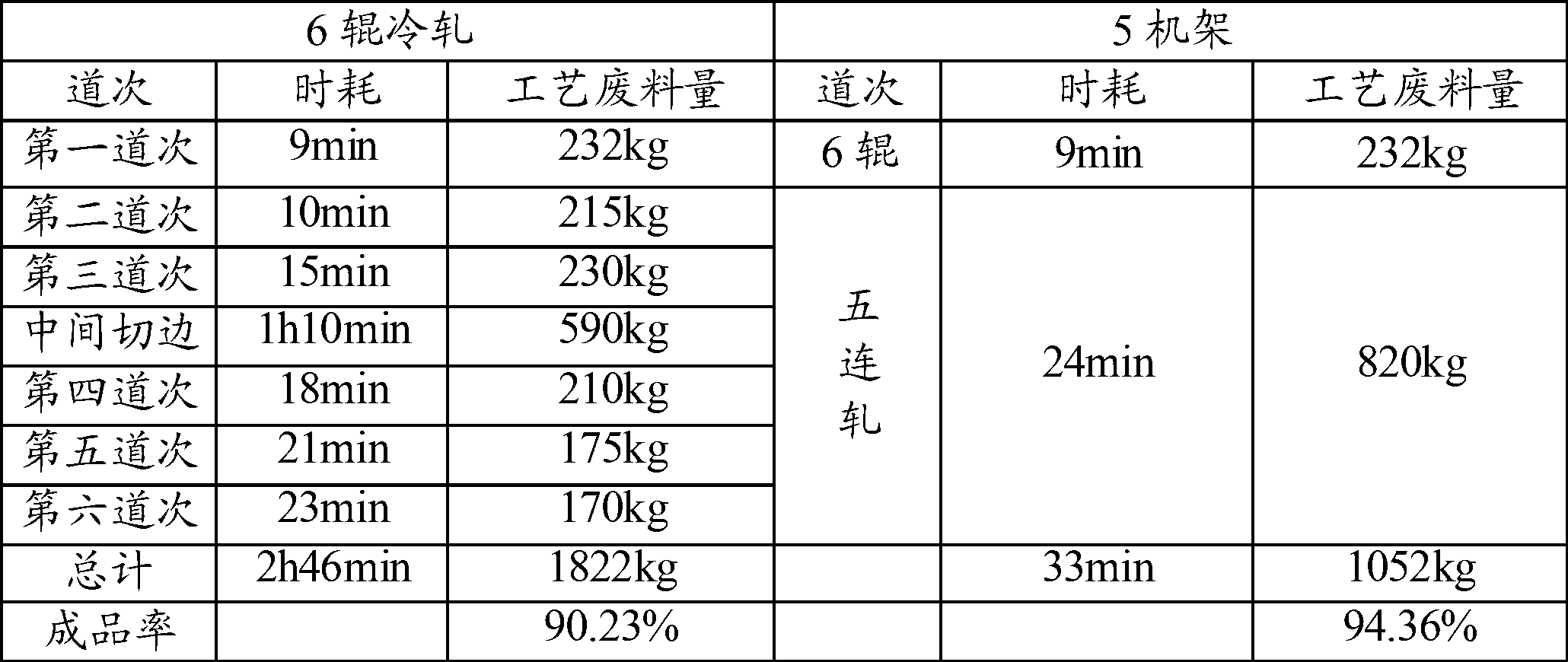

Embodiment 1

[0023] The alloy state of the 5182 aluminum alloy pull ring material base material described in this embodiment: 5182 / H48; the thickness of the finished product: 0.305mm; its production process includes: production process: melting and casting → sawing → milling → heating → hot continuous rolling → cold Rolling→tension bending straightening→coating→finished product shearing, the specific process parameters are as follows:

[0024] (1) Casting

[0025] The mass percentages of the chemical composition of molten aluminum after casting are: Si0.1108%, Fe0.262%, Cu0.0455%, Mn0.3823%, Mg4.7012%, Cr0.0388%, Zn0.0163%, Ti0.0094 %, V0.0164%, Ni0.0034%, Pb0.0022%, Cd0.0002%, Na0.0002%, and the rest is Al; the melting temperature is 749°C, the refining temperature is 734°C, and the casting temperature is 680°C.

[0026] (2) Heating: the heating temperature of the ingot is 495° C., and the holding time is 4 hours.

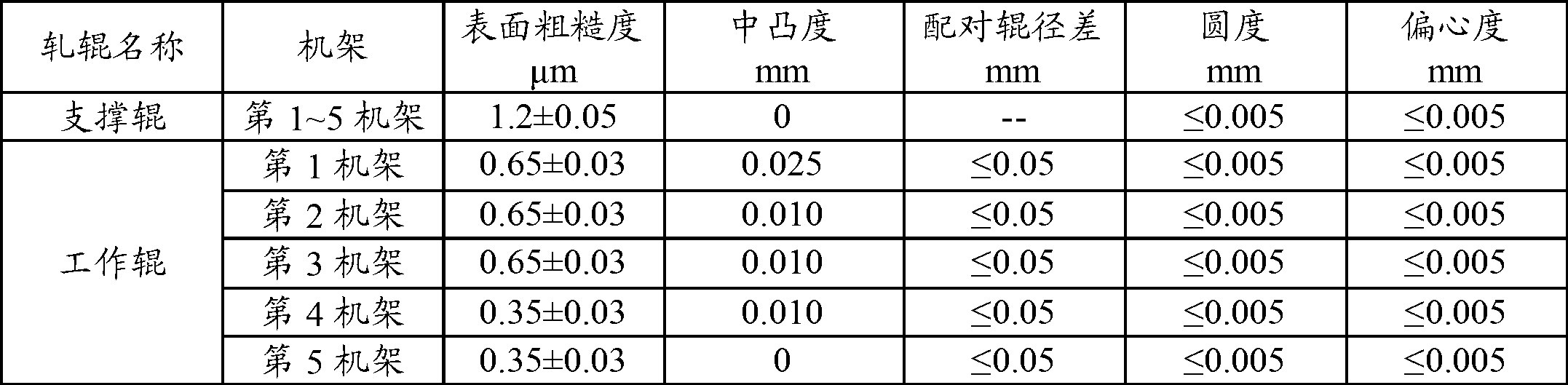

[0027] (3) Hot rolling: use 1+5 hot rolling mills, first roll 27 passes...

Embodiment 2

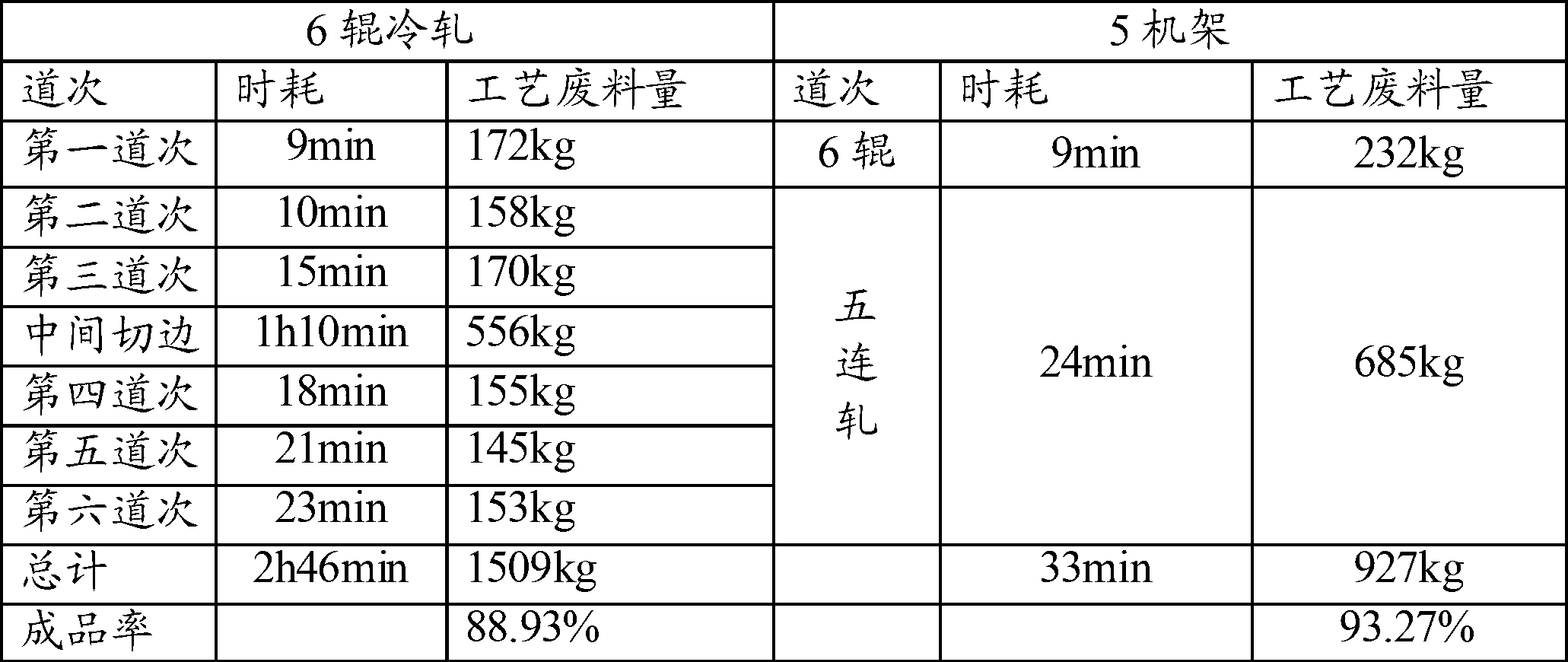

[0058] The alloy state of the 5182 aluminum alloy pull ring material base material described in this embodiment: 5182 / H48; the thickness of the finished product: 0.46mm; its production process includes: production process: melting and casting → sawing → milling → heating → hot continuous rolling → cold Rolling→tension bending straightening→coating→finished product shearing, the specific process parameters are as follows:

[0059] (1) Casting

[0060] The mass percentage of the chemical composition of molten aluminum after casting is: Si0.106%, Fe0.257%, Cu0.0452%, Mn0.3705%, Mg4.762%, Cr0.0316%, Zn0.0182%, Ti0.0095 %, V0.0164%, Ni0.003%, Pb0.0022%, Cd0.0002%, Na0.0001%, and the rest is Al; the melting temperature is 754°C, the refining temperature is 738°C, and the casting temperature is 683°C.

[0061] (2) Heating: the heating temperature of the ingot is 500° C., and the holding time is 4 hours.

[0062] (3) Hot rolling: use 1+5 hot rolling mills, first roll 27 passes in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com