Production technology of easily-cleaned and environment-friendly filter screen belt

A production process and filter screen technology, applied in the direction of filtration and separation, fabrics, perforated fabrics, etc., can solve the problems of small deformation, large differences, unstable effects, etc., and achieve improved service life, long service life, and easy cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

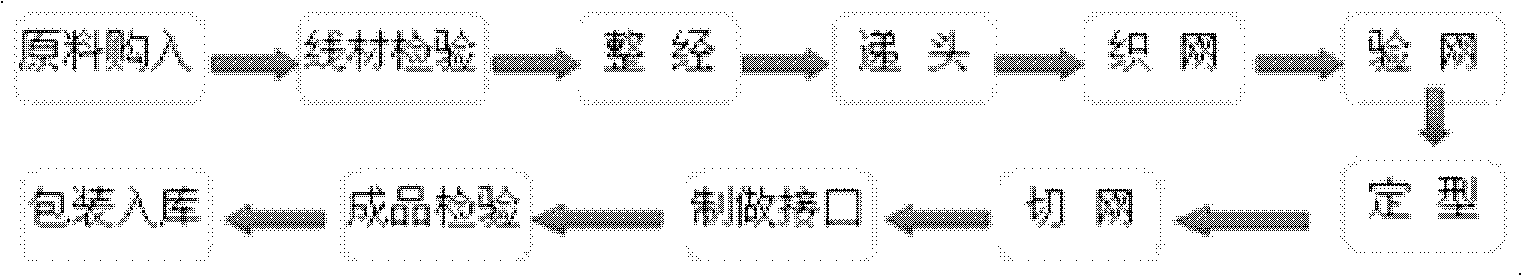

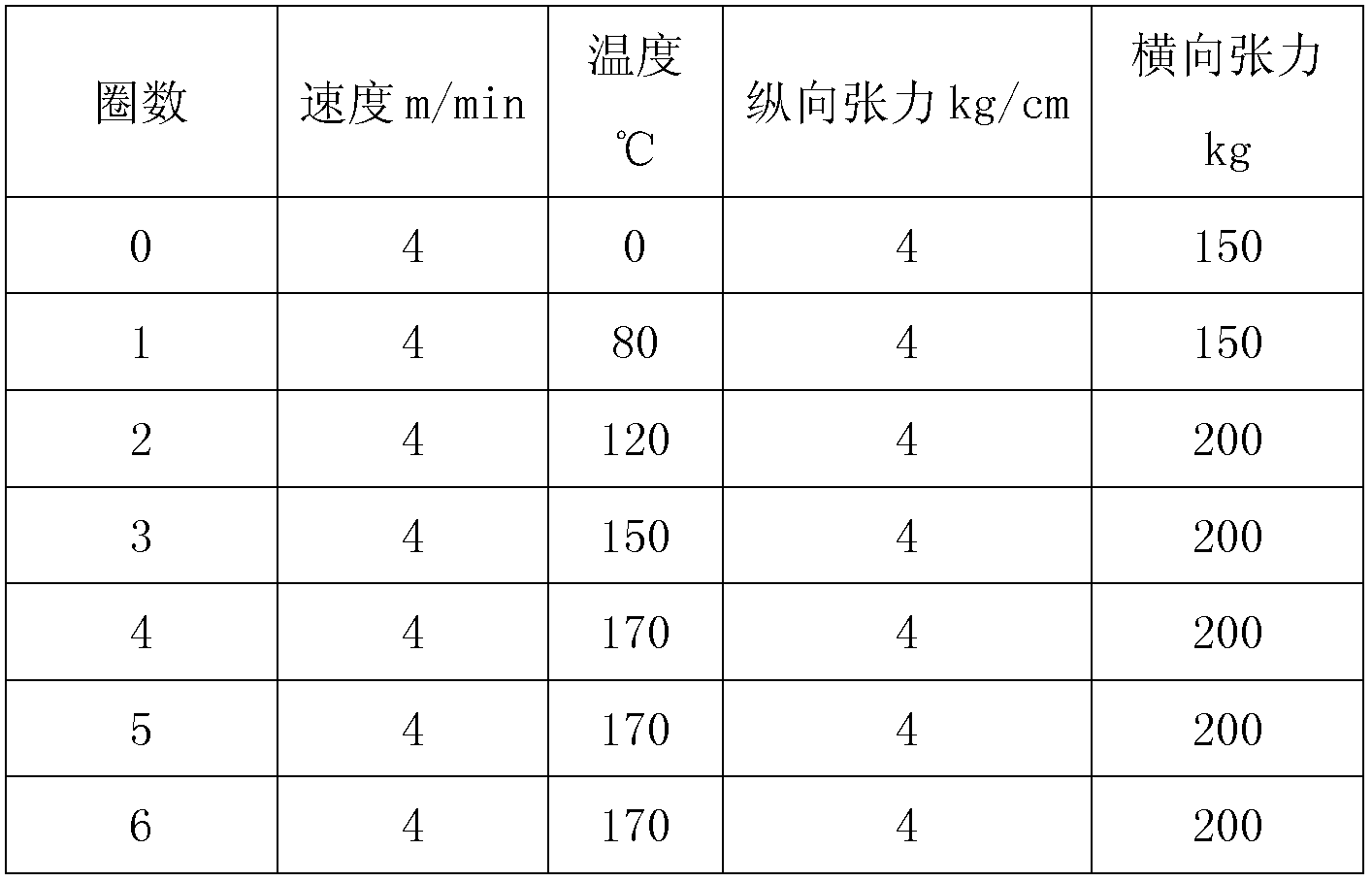

[0037] A production process of an easy-clean environmental filter belt, comprising the following steps:

[0038] (1) Purchase of raw materials

[0039] Purchasing German high-quality PET monofilament according to the requirements of the production plan according to the model, quality and quantity;

[0040] (2) Inspection

[0041] According to the requirements of the production plan, the indicators such as wire diameter, heat shrinkage, tensile strength, acid and alkali resistance are inspected item by item, and according to the specific production requirements, random inspections and full inspections are carried out in batches. The inspection indicators of this product are as follows:

[0042] Warp: Ф0.50mm, tensile strength: 540 N / mm 2 , heat shrinkage value: 6%,

[0043] Weft: Ф0.85mm, tensile strength: 520N / mm 2 , heat shrinkage value: 3%;

[0044] (3) Warping

[0045] The tension of each monofilament is required to be uniform, warping speed: 40m / min, tension:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com