Oil filler cap assembly

A technology of oil filling port cover and oil filling port, which is applied in the direction of adding/discharging lubricant and lubricating parts, etc., which can solve problems such as poor ventilation, increased engine pressure, personal safety issues, etc., and achieves simple structure and avoids interior The effect of increasing pressure and protecting work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

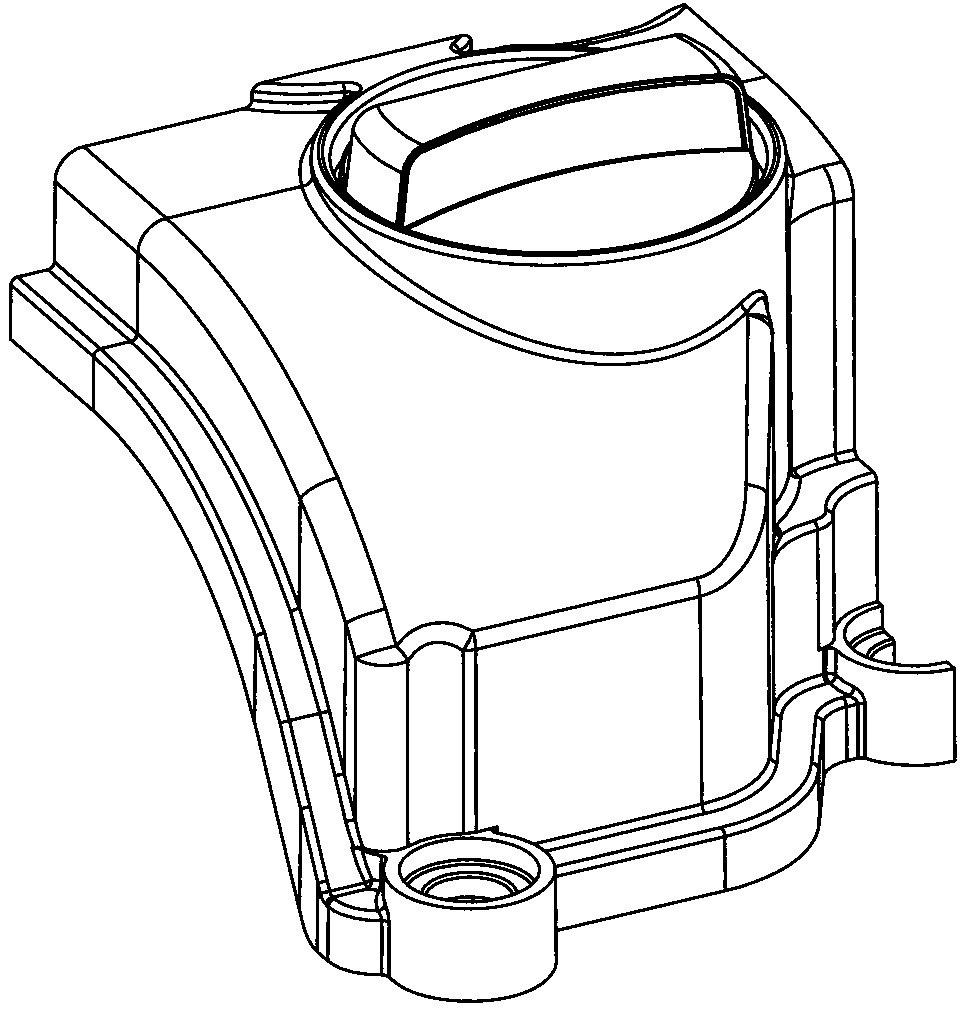

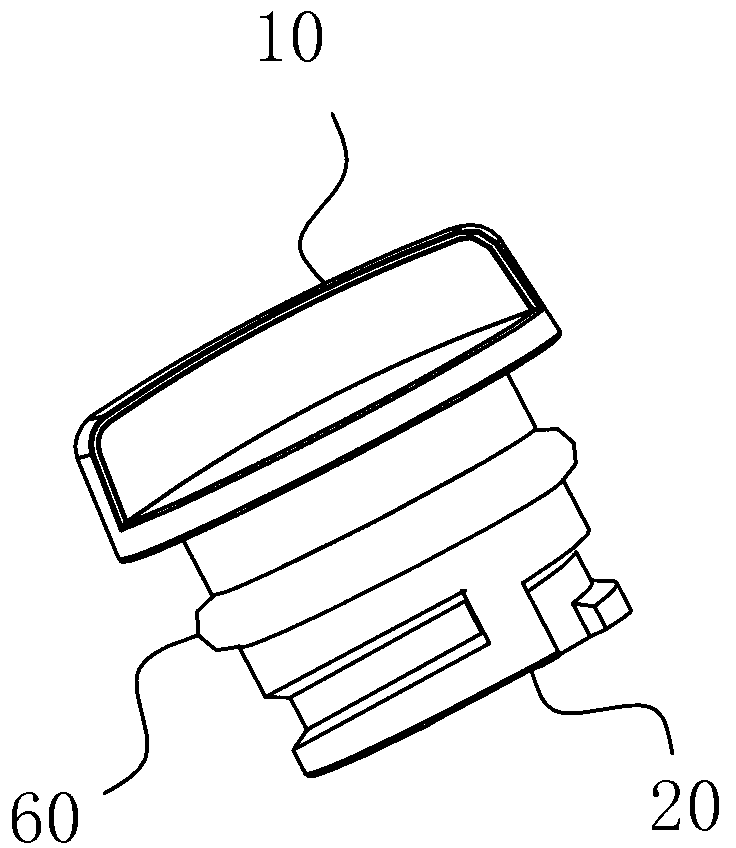

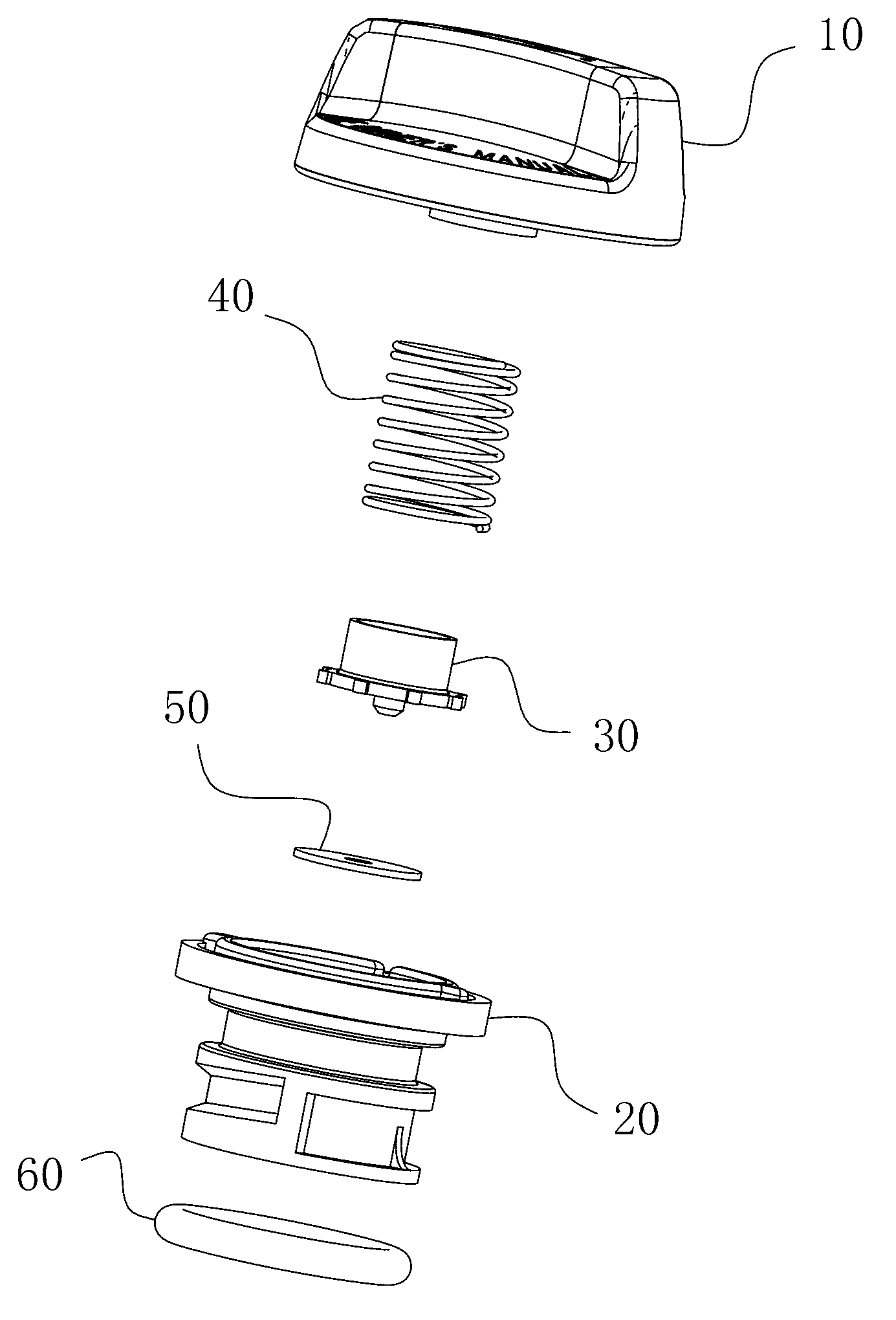

[0012] An oil filler cap assembly, the fuel filler cap assembly has a one-way valve structure, at least including an upper cover 10, and a valve housing located under the upper cover 10 for forming a plug-in and airtight fit with the fuel filler part 20 and a valve core 30 arranged in the valve housing part 20; the valve housing part 20 is cylindrical in shape and its bottom is opened with a hole 21 through the bottom wall, and the valve core 30 is connected with the upper cover 10 and / or The valve housing parts 20 form an elastic fit, and the elastic direction is parallel or intersected with the axial direction of the valve housing part 20. The bottom of the valve core 30 extends to the bottom wall of the valve housing part 20 and forms a gap between the upper channel 21 and the elastic direction. The openable and closable surfaces are abutted against each other; there is a gap between the valve core 30 and the inner wall of the valve housing 20 and the gap is set along with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com