Silencer for exhaust system of gasoline engine

A gasoline engine and exhaust system technology, applied to engine components, machines/engines, noise reduction devices, etc., can solve the problems of large metal vibration, insufficient noise reduction, and loud noise, so as to keep the airflow soft and stable, eliminate kinetic energy and Effects of vibration and metal noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

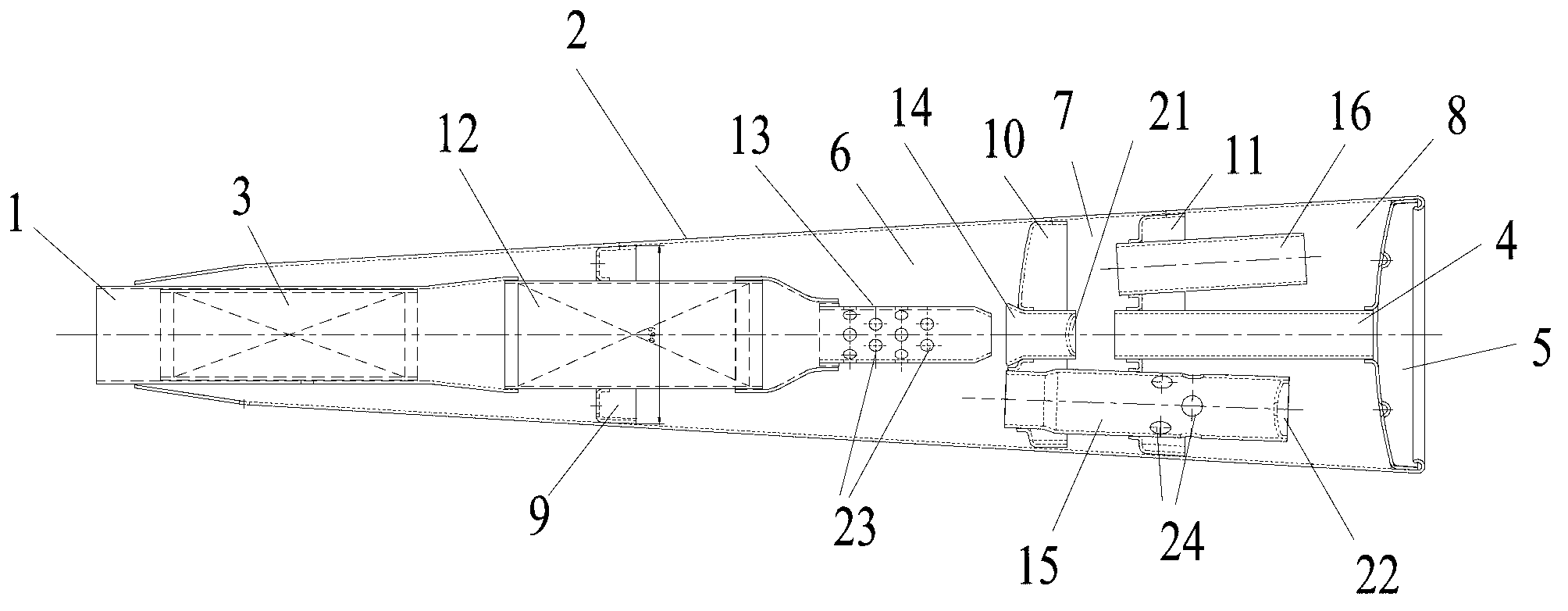

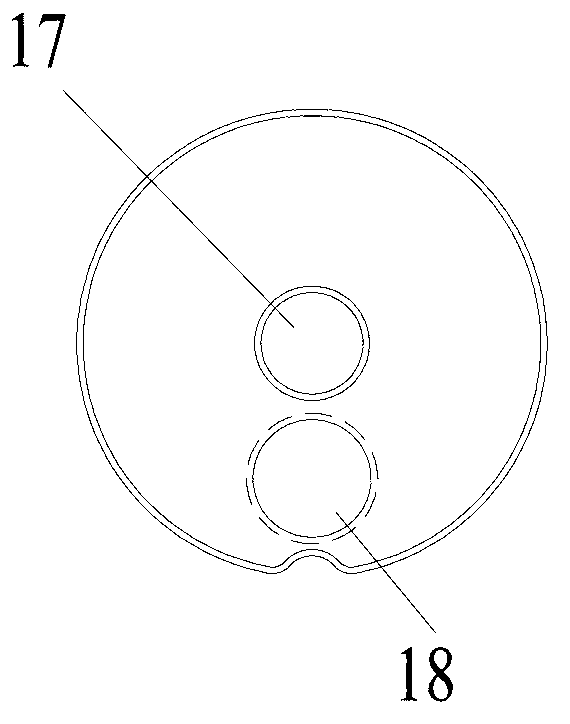

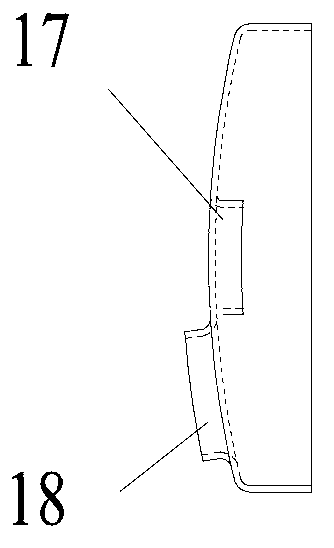

[0037] The structure schematic diagram of Embodiment 1 of the muffler used in the gasoline engine exhaust system of the present invention is as follows figure 1 As shown, the muffler includes a front exhaust pipe 1, a muffler cylinder 2, a catalytic converter 3 arranged in the muffler cylinder 2, a muffler assembly, a tailpipe 4 and a tail cover 5 connected in sequence; wherein, the muffler assembly It includes a one-hole plate 9, a two-hole plate 10 and a three-hole plate 11 which divide the muffler cylinder 2 into the first cavity 6, the second cavity 7 and the third cavity 8 in sequence, a connecting pipe 12, and the pipe wall is set There are a first-level porous pipe 13 with several second muffler holes 23 , a first-level muffler pipe 14 , a second-level muffler pipe 15 and a draft pipe 16 . The connecting pipe 12 is inserted on a hole plate 9, one end on one side of the hole plate 9 is connected to the tail end of the catalytic converter 3, and the other end on the other...

Embodiment 2

[0046] This embodiment differs from Embodiment 1 in that:

[0047] (1) The structure schematic diagram of Embodiment 2 of the muffler used in the gasoline engine exhaust system of the present invention is as follows: Figure 6 As shown, the second-level muffler pipe 15 is located on the wall of the third cavity 8 and is provided with a first muffler hole 24, and the first muffler hole 24 in this embodiment is a side facing the tailpipe 4 The openings on the wall, the first muffler hole 24 can not only make the gas discharged to the third chamber 8 after canceling each other in the secondary muffler pipe 15, and the discharged air flow impacts the round pipe surface of the tail pipe 4, which can Diverging, buffering and softening the airflow, avoiding the impulsive airflow impacting the tailpipe round tube surface at the same time, forming a sequential dispersion and impacting the tailpipe round tube surface, thereby reducing the metal noise emitted by the impact.

[0048] (2)...

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that the first silencing hole is not provided on the secondary silencing pipe. Cavity, and one end arranged in the third cavity is not provided with a blocking cover one, and the two ends of the secondary muffler pipe are open ends. Other structures of the muffler in this embodiment are the same as those of the muffler in Embodiment 1.

[0052] The muffler in this embodiment works like this: the engine airflow enters the first-stage porous pipe from the tail end of the catalytic converter through the connecting pipe, the airflow discharged from the first-stage porous pipe enters the first-stage muffler pipe for consumption, and a part of the pulsed airflow hits first The wall of the first-stage muffler pipe and the second cover consume part of the kinetic energy. At this time, the pulsed airflow rebounding toward the air intake direction is constantly opposed to another part of the pulsed airflow rushing towards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com