High-supercharged two-stroke direct injection engine and ventilation method thereof

An in-cylinder direct injection and engine technology, which is applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of high combustion consumption rate and pollutant emissions, enhance active control capabilities, and reduce harmful emissions. , the effect of avoiding consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

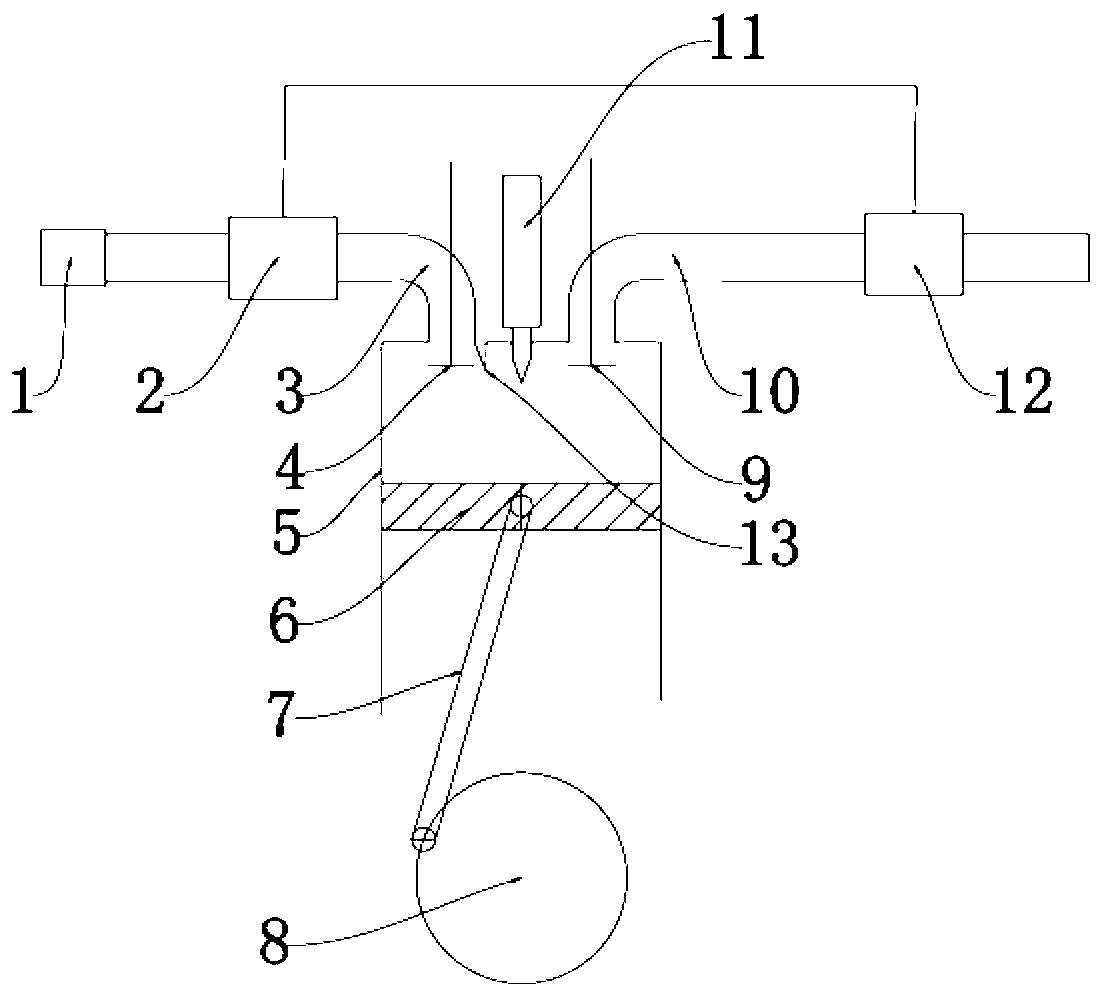

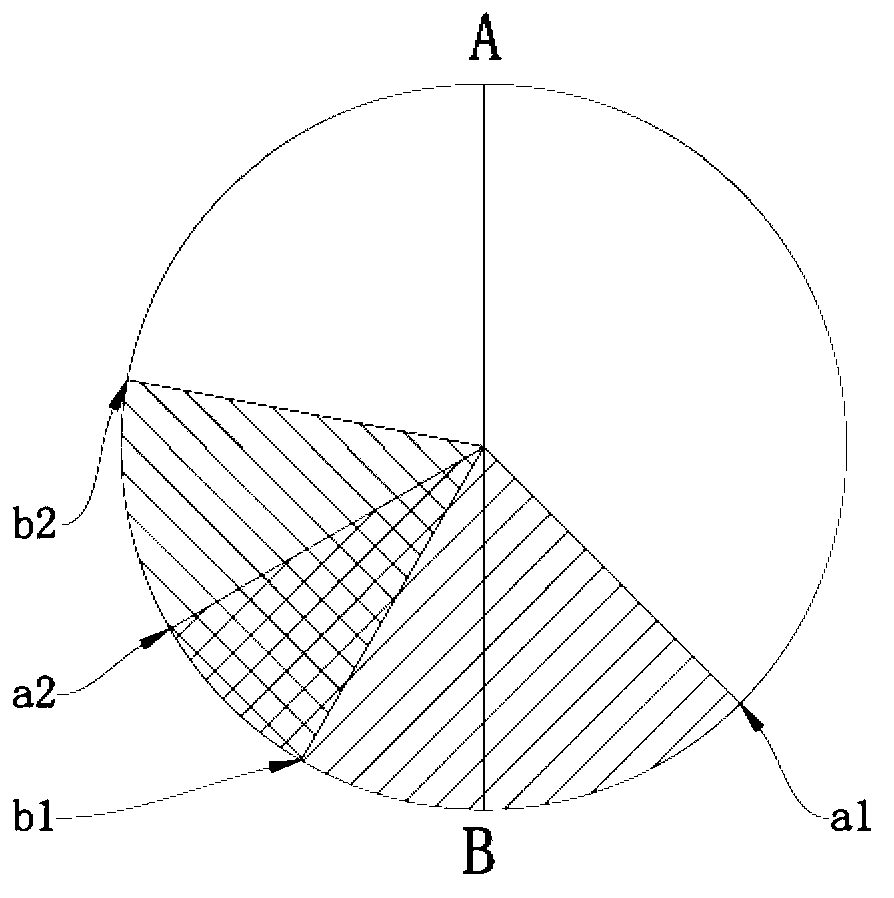

[0029] see figure 1 . The highly boosted two-stroke in-cylinder direct injection engine described in this embodiment includes a cylinder 5, a piston 6 is installed in the cylinder, and the piston 6 is connected to a crankshaft 8 through a connecting rod 7. A fuel injector 11 is installed at the center of the top wall of the cylinder 5 for injecting fuel into the cylinder 5 . An intake hole and an exhaust hole are also arranged on the top wall of the cylinder 5, and the fuel injector 11 is located at the midpoint of the line between the intake hole and the exhaust hole. An intake valve 4 is installed on the intake hole, and the intake hole communicates with the intake passage 3. An air filter 1 and a high-pressure ratio supercharger 2 are installed on the intake passage 3. The air filter 1 is located at the high-pressure than Supercharger 2 before. An air guide screen 13 is arranged on the edge of the air intake hole, and the air guide screen 13 is located on one side of the...

Embodiment 2

[0032] This embodiment is to illustrate the ventilation method of the high-pressure two-stroke direct-injection engine described in Embodiment 1. The high pressure ratio supercharger 2 supercharges the fresh air to more than 0.6MPa, on the one hand, it is convenient to replace the exhaust gas in the cylinder, and on the other hand, it maintains a higher initial pressure inside the cylinder. After the piston 6 completes the work of the previous cycle, the exhaust valve 9 is opened before the bottom dead center of this cycle, and the engine starts the free exhaust process. Piston 6 begins to move upward after turning over the bottom dead center, and the engine enters the forced exhaust stage. At a certain moment after the bottom dead center, the intake valve 4 opens, and the high-pressure fresh air in the intake passage 3 enters the cylinder 5 after passing through the intake valve 4. The burned gas in the cylinder is replaced, and part of the fresh air mixed with the burned ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com