Mixing circular incinerator

An incinerator, circular technology, applied in the incinerator, combustion type, combustion method and other directions, can solve the problems of collision, increase the difficulty of operating the incinerator, and the air supply branch pipe cannot continue to rotate, and achieve the effect of preventing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

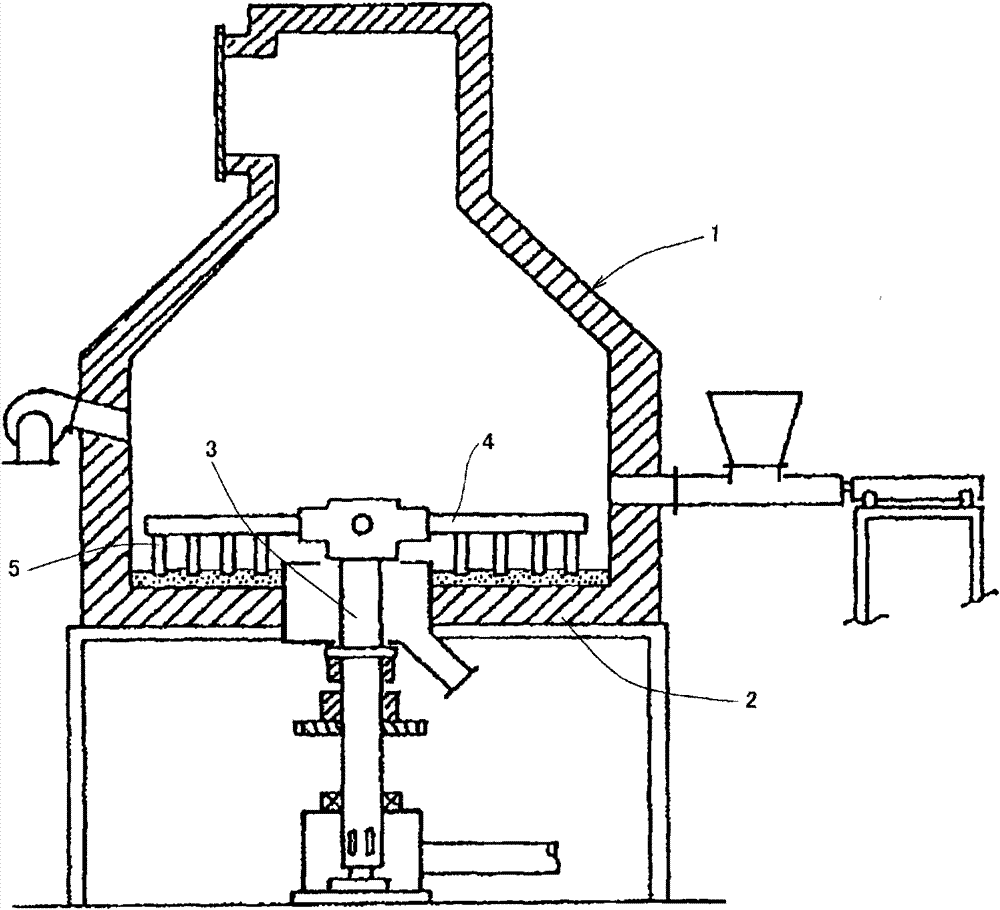

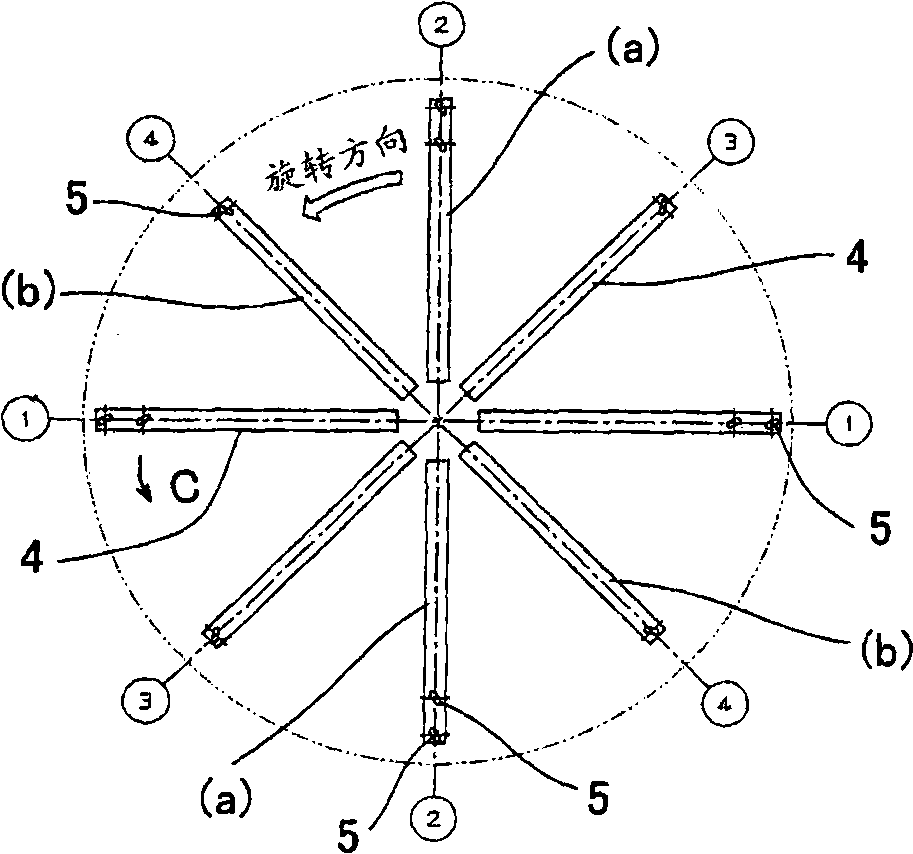

[0034] figure 1 A schematic longitudinal sectional view of the stirring circular incinerator 1 of the present invention is shown. This agitated circular incinerator 1 is provided with a rotary air supply shaft tube 3 protruding from its lower side to the inside of the furnace at the center of the hearth 2 in the circular furnace, and from the top of the rotary air supply shaft tube 3 A plurality of rotating arms (hereinafter referred to as air supply branch pipes) 4 are radially extended, and a plurality of air supply branch pipes 5 are formed protruding from the surface of each of the air supply branch pipes 4 toward the hearth 2 .

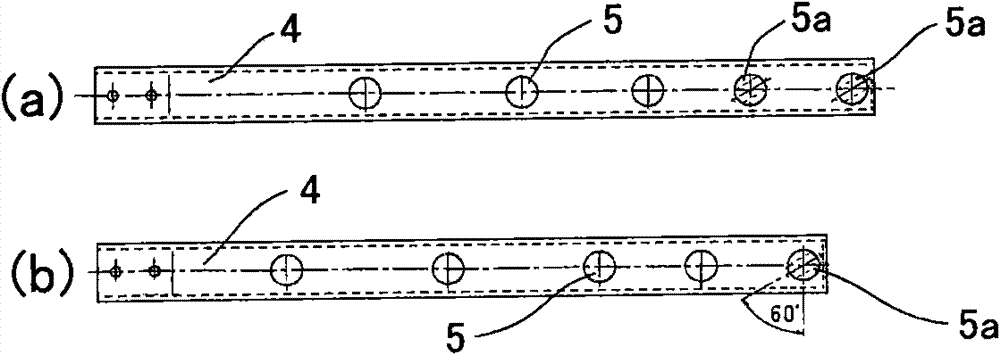

[0035] For the front end of each air supply branch pipe 5 among the plurality of air supply branch pipes 5 or the air supply branch pipe 5a located at the front end and its inner side, its cross-sectional shape is set to a flat shape, and relative to the air supply branch pipe The extending direction of 4 is installed obliquely, so that the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com