Polarization-maintaining fiber grating two-dimensional vector vibration sensor

A polarization-maintaining optical fiber and two-dimensional vector technology, applied in instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as hidden dangers, safety, and susceptibility to electromagnetic interference, achieving good repeatability and overcoming stability The effect of falling and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

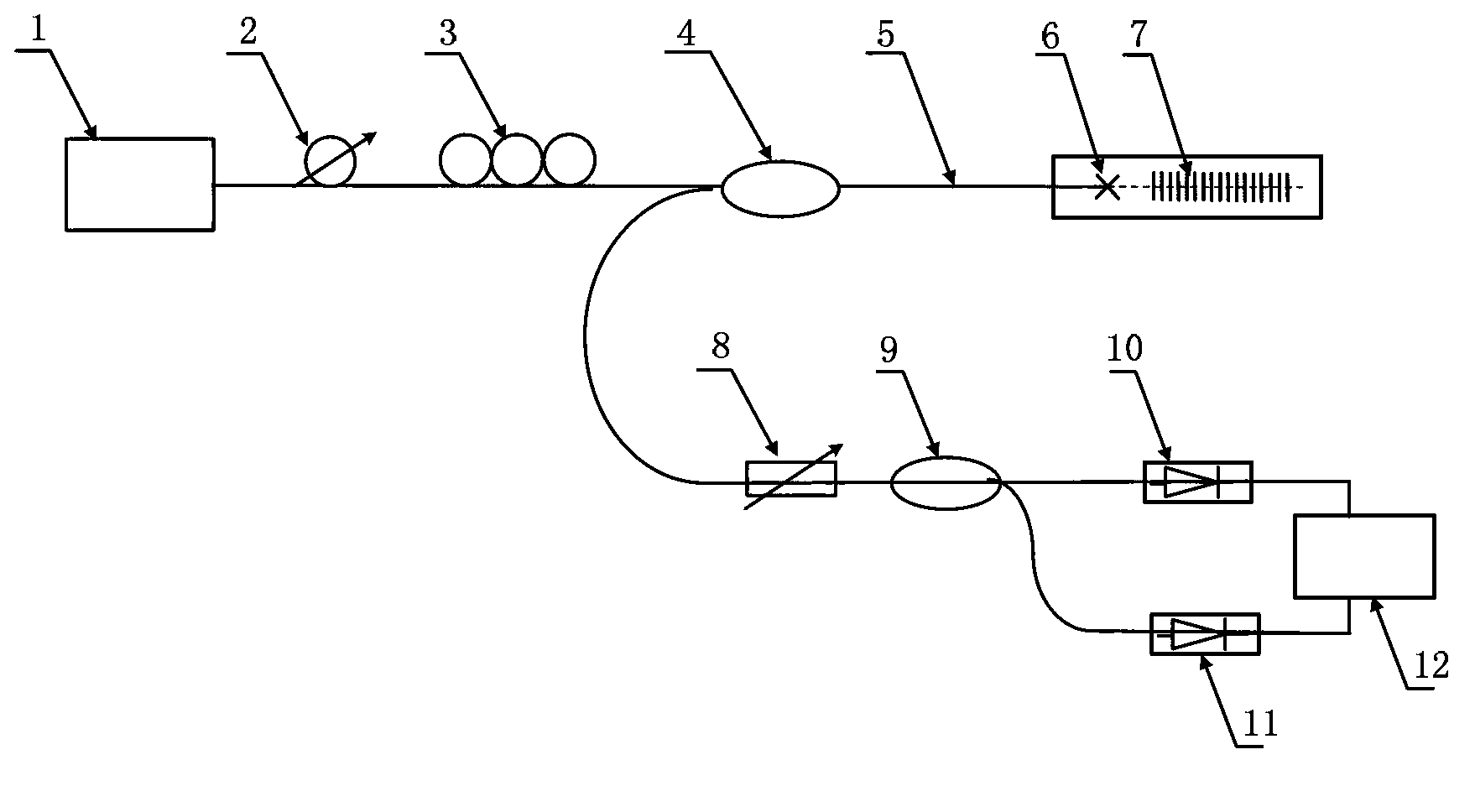

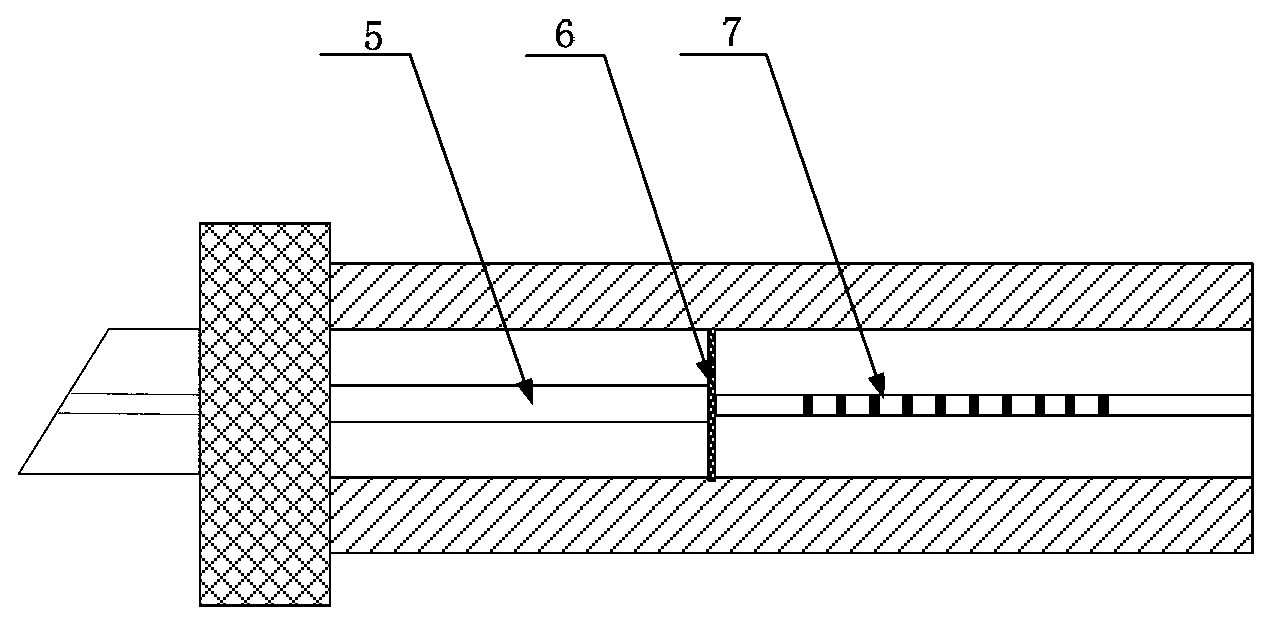

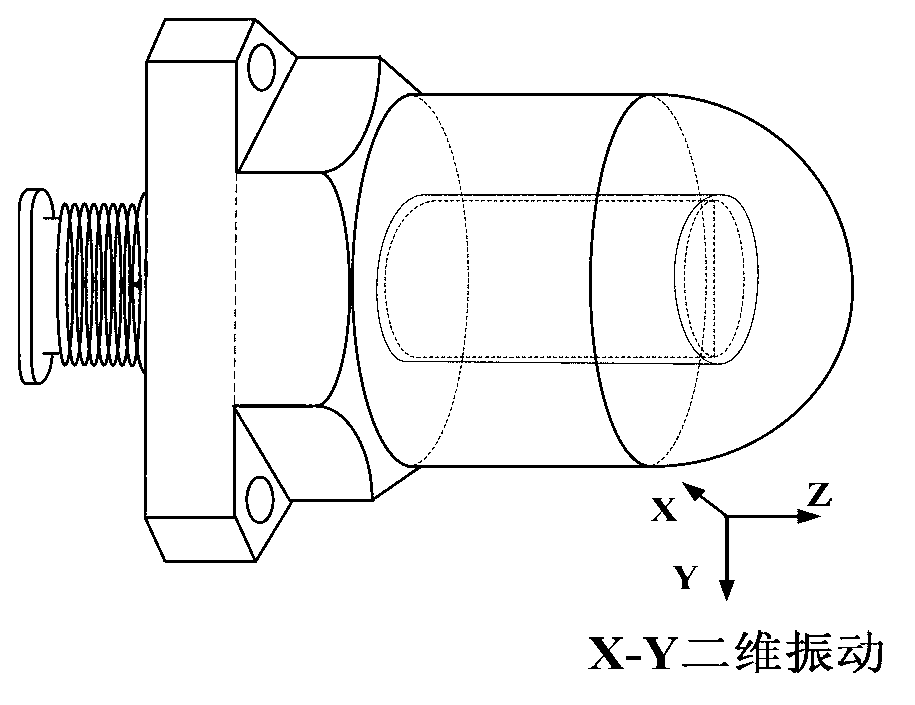

[0035] Such as figure 1 As shown in and 2, the polarization-maintaining fiber grating two-dimensional vector vibration sensor described in this embodiment includes a broadband light source 1, a polarization control unit, a sensing probe and an orthogonal polarization demodulation unit, the polarization control unit, the sensor The probe and the orthogonal polarization demodulation unit are connected through an optical fiber circulator 4 . Couplers can also be used in practical applications. The polarization control unit includes a polarizer 2 and a polarization controller 3, and the broadband light source 1, the polarizer 2 and the polarization controller 3 are connected in sequence. The sensing probe includes an optical fiber wire 5 and an optical fiber probe, the optical fiber probe includes a polarization-maintaining fiber grating 7 and a cladding-core energy recoupling structure 6, and the optical fiber probe is connected to the optical fiber circulator 4 through the opti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com