Array base plate, manufacturing method thereof and liquid crystal display device

A technology of array substrates and substrate substrates, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., and can solve problems such as large gate size, increased feed-in voltage ΔVp value, and increased TFT inter-electrode capacitance value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

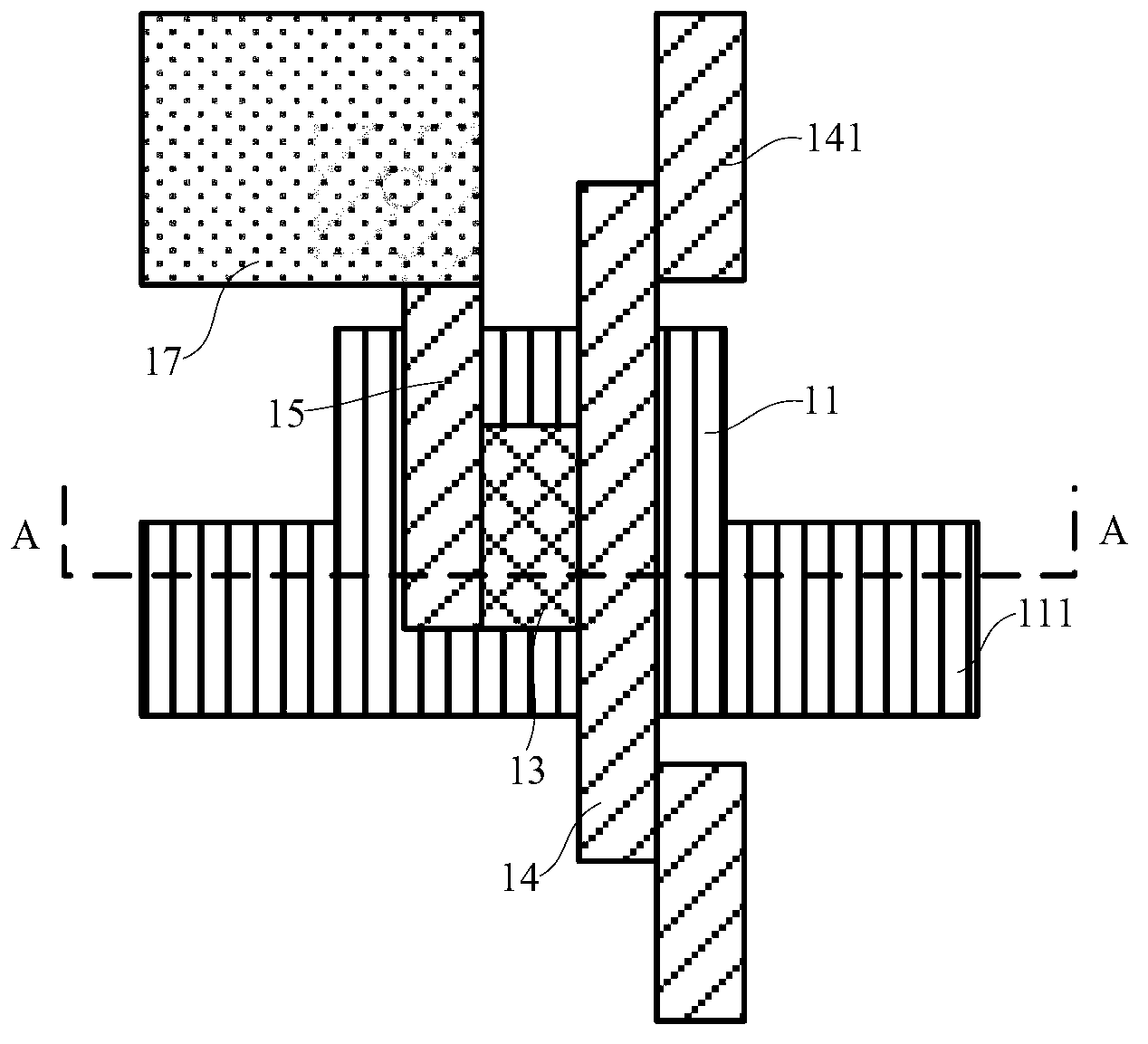

[0061] Embodiment 1. The structure of the array substrate in the embodiment of the present invention is as follows: Figure 3A and Figure 3B shown, where Figure 3B for Figure 3A The schematic diagram of the cross-sectional structure of the B-B direction of the array substrate shown, the array substrate of this embodiment includes:

[0062] substrate substrate 30;

[0063] The light-shielding layer 38 located on the base substrate 30 corresponding to the active layer 33, the light-shielding layer 38 is used to block the light entering the active layer 33 (that is, the light emitted from the backlight module), so that the active Layer 33 will not be exposed to light;

[0064] The grid 31 located on the light-shielding layer 38;

[0065] a gate insulating layer 32 on the gate 31;

[0066] an active layer 33 located on the gate insulating layer 32;

[0067] a source 34 and a drain 35 on the active layer 33;

[0068] A protection layer 36 located on the source electrode ...

Embodiment 2

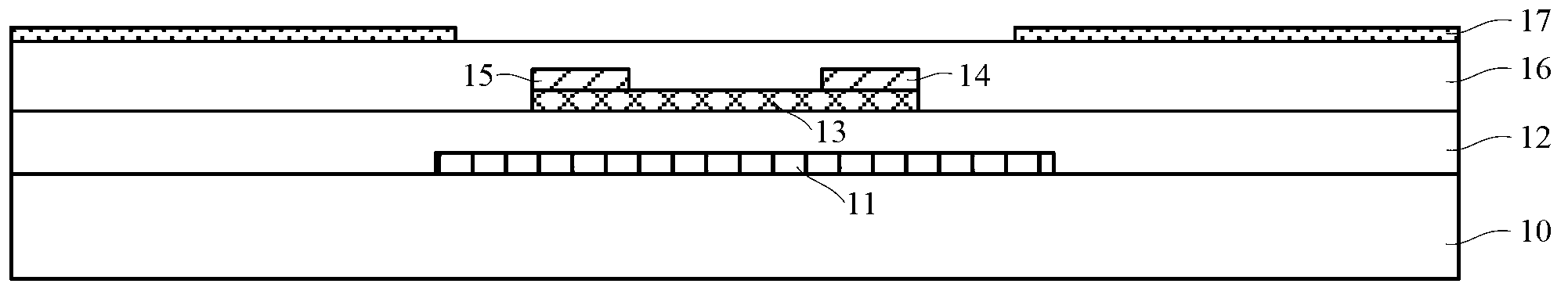

[0096] Embodiment 2. The structure of the array substrate in the embodiment of the present invention is as follows Figure 6A and Figure 6B As shown, among them, Figure 6B for Figure 6A The B-B direction sectional schematic diagram of the array substrate shown in this embodiment The array substrate includes:

[0097] substrate substrate 60;

[0098] A gate 61 located on the base substrate 60;

[0099] a gate insulating layer 62 on the gate 61;

[0100] A light-shielding layer 63 located on the gate insulating layer 62 and corresponding to the active layer 64, the light-shielding layer 63 is used to shield the light entering the active layer 64 (that is, the light emitted from the backlight module), so that there are The source layer 64 will not be irradiated by light;

[0101] The active layer 64 located on the light shielding layer 63;

[0102] a source 65 and a drain 66 on the active layer 64;

[0103] A protective layer 67 located on the source electrode 65 and the...

Embodiment 3

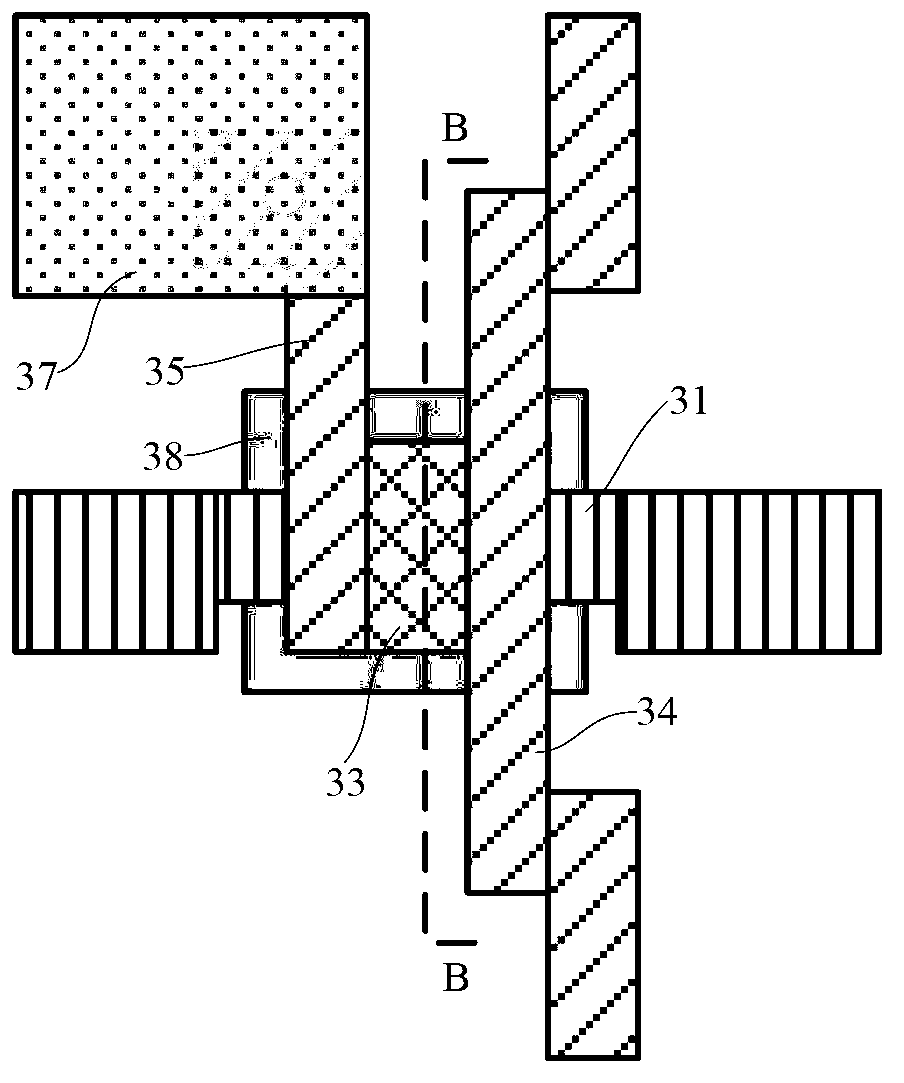

[0130] Embodiment 3. The structure of the array substrate in this embodiment is as follows: Figure 8A and Figure 8B As shown, among them, Figure 8B for Figure 8A The C-C direction sectional structure schematic diagram of the array substrate shown, the array substrate includes:

[0131] substrate substrate 800;

[0132] The light-shielding layer 801 and the pixel electrode 802 are located on the same layer on the base substrate 800, wherein the light-shielding layer 801 is located on the base substrate 800 at a position corresponding to the active layer 806, and is used to block light incident on the active layer 806 Light (that is, the light emitted from the backlight module), so that the active layer 806 will not be irradiated by light;

[0133] An insulating layer 803 located on the light-shielding layer 801, wherein the material of the insulating layer 803 can be silicon nitride or silicon oxide, etc.; the thickness of the insulating layer 803 is 200 nanometers to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com