Low-inductance and large-power power electronic capacitor

A technology of power electronics and capacitors, which is applied in the field of high-power power electronic capacitors, can solve problems such as large self-inductance of capacitors, thermal breakdown of capacitors, and large parasitic inductance, and achieve the effects of reducing self-inductance, suppressing inductance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

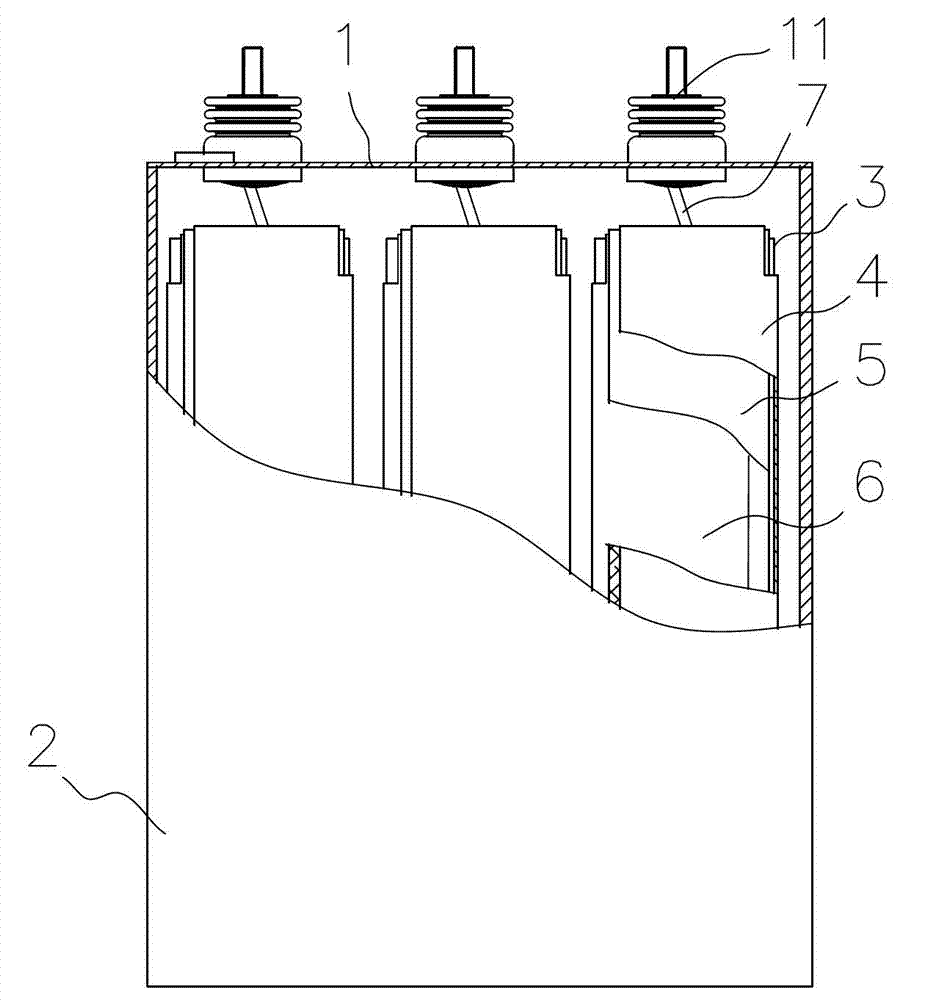

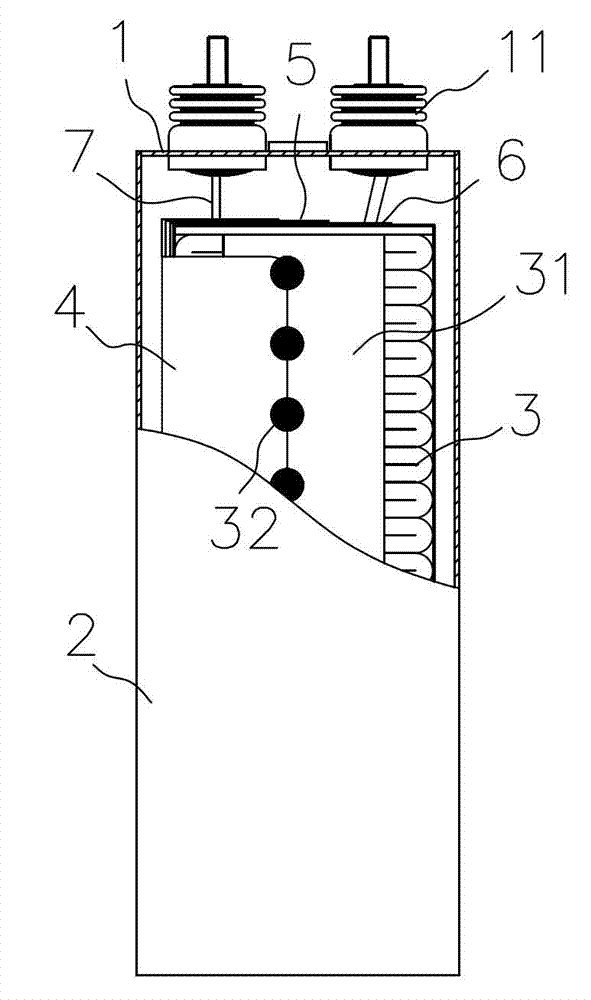

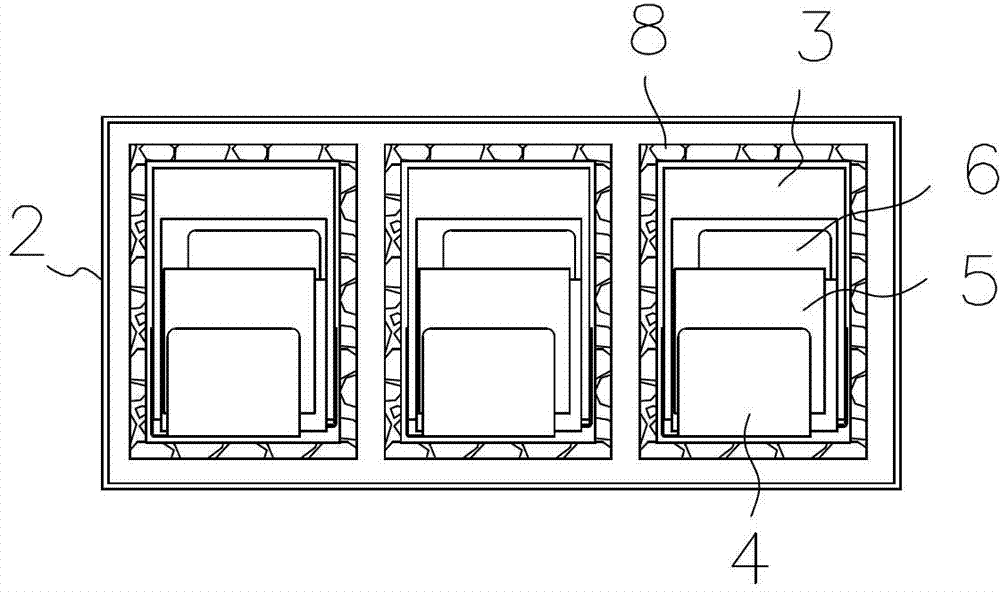

[0013] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a cover plate assembly 1 , a casing 2 and a capacitor core group 3 . The capacitor core group can be a multi-core group or a single-core group. In this example, the capacitor core group 3 has three groups. The capacitor core group 3 is fixed in the insulating groove 8 at the bottom of the shell 2. The gold surface 31 is electrically connected with lead copper strips 4, 6 used as positive and negative electrodes respectively, figure 2 The middle solder joint 32 is between the lead copper strip 4 and the gold-sprayed surface 31 .

[0014] Lead out copper strip structure such as Figure 4 shown. The two lead-out copper strips 4, 6 respectively include gold-sprayed surface connection parts 41, 61 electrically connected to the gold-sprayed surface 31 of the capacitor core group, and are arranged on the top of the capacitor core group 3 for electrical connection with the lead-out terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com