A trapezoidal cross-section separated transformer

A trapezoidal section, separate technology, applied in the direction of transformer/inductor core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problem of high core utilization, low coupling coefficient, The problem of high coupling coefficient can achieve the effect of improving coupling coefficient, uniform magnetic field distribution, and reducing self-inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

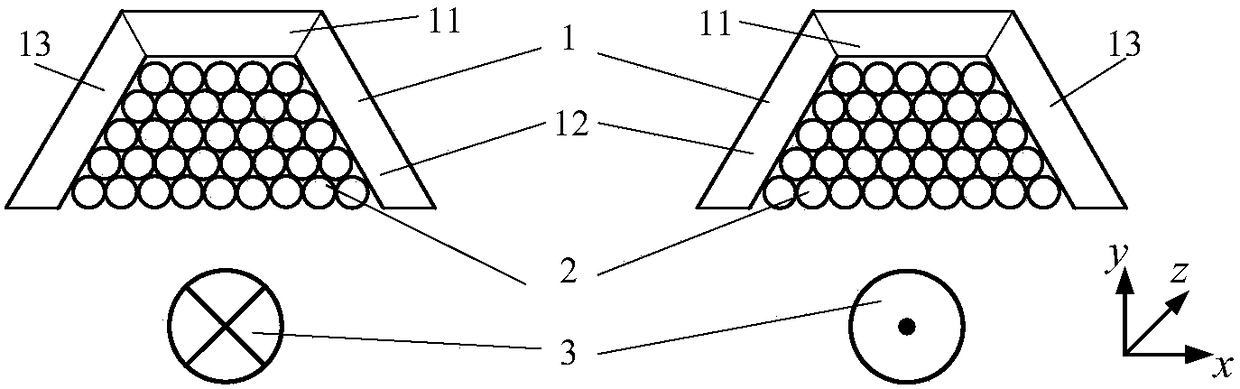

[0033] The two-dimensional section of Example 1 of the present invention is as follows Figure 1a shown. The inner surface 12 and the outer surface 13 of the secondary magnetic core 1 are inclined outward, and the inner surface 12 and the outer surface 13 are connected to the bottom surface 11 of the magnetic core 1 at an obtuse angle. The cross section of the secondary magnetic core 1 is trapezoidal, the inner surface 12 and the outer surface 13 of the secondary magnetic core 1 and the bottom surface 11 of the secondary magnetic core 1 enclose a trapezoidal groove, and the secondary coil 2 is wound on the secondary magnetic core 1 In the groove, the coil is wound in 5 layers. The primary coil 3 is placed on the window side of the secondary magnetic core 1, and connected in the forward direction to form a loop. The winding method of the secondary coil 2 is as follows: Figure 1b As shown, the coil wires are connected in the forward direction. The secondary magnetic cores 1...

Embodiment 2

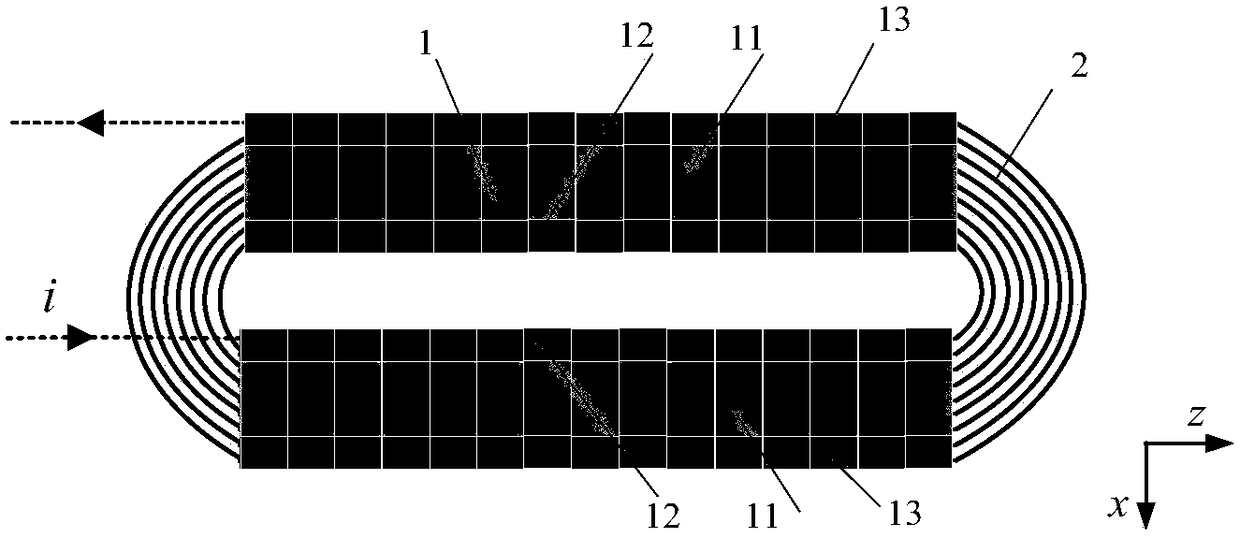

[0041] The two-dimensional section of Example 2 of the present invention is as follows Figure 2a As shown, looking down as Figure 2b As shown, the secondary core is at Figure 2b The z-axis direction is equally spaced and sparsely arranged, wherein the arrangement interval is equal to the width of the magnetic core in the z-axis direction. In the case that the primary and secondary coil diameters, number of turns and air gap length of the trapezoidal cross-section separated transformer are the same, only the arrangement interval of the secondary magnetic core is changed. In the case where the secondary magnetic cores are arranged at equal intervals, when the magnetic core arrangement interval does not exceed the magnetic core width, the coupling coefficient of the separated transformer in embodiment 2 is the same as that of embodiment 1 in which the secondary magnetic cores are densely arranged The difference is not big, but the amount of magnetic core is reduced, the loss...

Embodiment 3

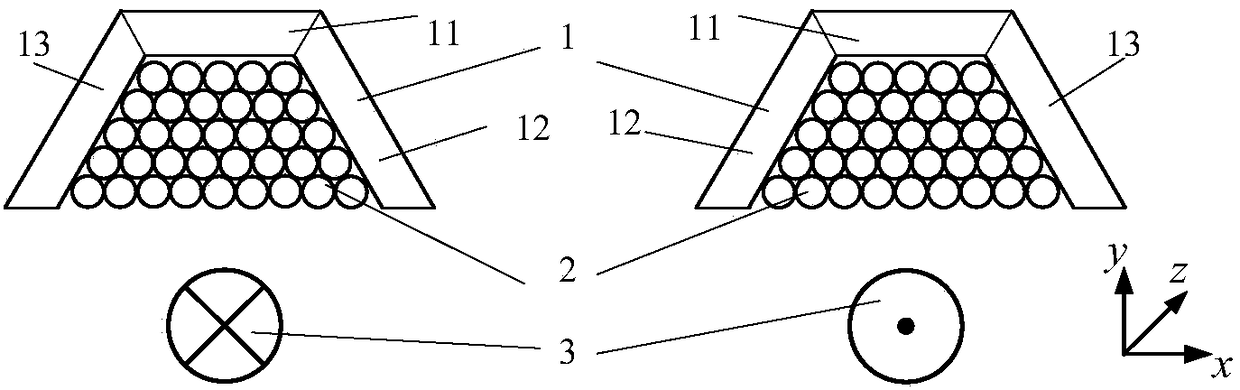

[0043] The cross section of embodiment 3 of the present invention is as image 3 shown. Embodiment 3 is composed of the bottom surface 21 of the secondary magnetic core, the inner surface 22 of the secondary magnetic core, the outer surface 21 of the secondary magnetic core, the secondary coil 2 and the primary coil 3 . The number of turns of the secondary coil in Example 3 is the same as the number of turns of the secondary coil in Example 1 and Example 2, the secondary coil is laid in 3 layers, and the trapezoidal secondary is flatter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com