Thin-film capacitor applied to flexible direct-current power transmission system and production process thereof

A technology for film capacitors and power transmission systems, which is applied in the direction of film/thick film capacitors, laminated capacitors, fixed capacitor electrodes, etc., can solve the problem that the performance of high-voltage film capacitors cannot meet the application requirements of flexible direct transmission systems, and achieve the purpose of adding safety isolation films , reduce its own inductance, reduce the effect of uneven shunt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

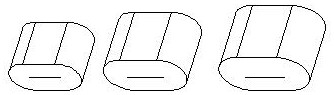

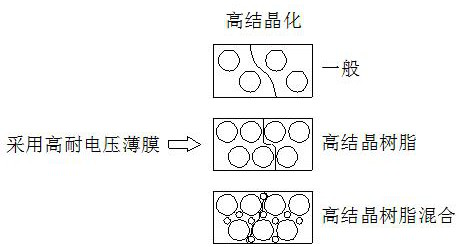

[0024] A film capacitor used in flexible direct transmission systems, the film thickness of the film capacitor is 2-10um, see figure 1 As shown, the sizes of the cores wound by 2μm, 2.5μm, and 3μm films are given from left to right. The thinner the film thickness, the smaller the core size. The capacitance is inversely proportional to the square of the film thickness. Miniaturization is the most The effective method is to reduce the thickness of the film, but the pressure resistance of the film is proportional to the thickness. How to ensure its pressure resistance has become a technical difficulty. Therefore, the film of the film capacitor is made of a mixture of highly crystalline resins. See figure 2 As shown, the thickness of the film is reduced under the premise of ensuring the pressure resistance, and the resin is polypropylene.

[0025] Among the various failure modes of metallized film capacitors, breakdown is the most serious mode. Not only the attenuation of capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com