High-level copper circuit board and manufacturing method thereof

A circuit board production and circuit board technology, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit parts, etc., can solve the problems of thin solder resist ink for thick copper lines, difficulty in improving the yield rate, and air bubbles in the dry film, and achieve Improve the yield rate, improve thermal management performance, and avoid the effects of film bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

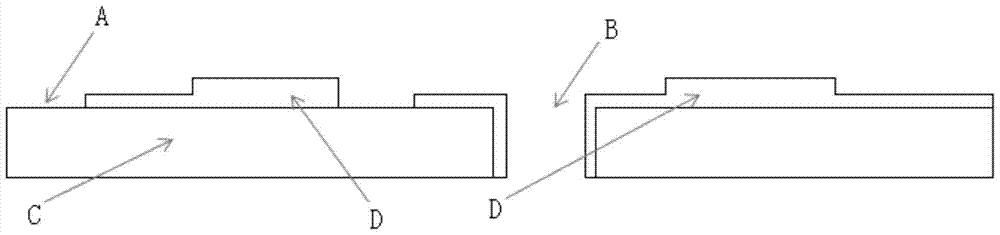

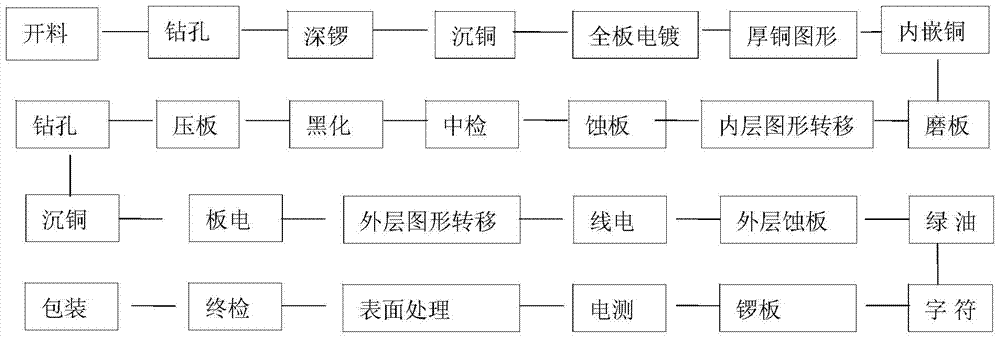

[0046] A kind of 2OZ / 12OZ high step copper circuit board (multi-panel) manufacturing method, according to figure 2 The process flow shown proceeds as follows:

[0047] (1) Pre-process: Including cutting, drilling and other processes, it is produced according to the conventional process.

[0048] (2) Deep gong: Before work, measure the flatness of the operation table to control the operation table at a horizontal height, and detect the warpage of the circuit board that requires deep gong to ensure that the warpage does not exceed 0.4%. Then place the inner layer of the multi-layer board horizontally, use a gong machine to deep-drill the inner layer according to the preset thick copper line direction and depth, and drill thick copper line slots on the circuit board that are consistent with the preset thick copper line direction.

[0049] The gong machine is placed on a platform made of cement and cushioning materials after the ground has been compacted, and the weight of the g...

Embodiment 2

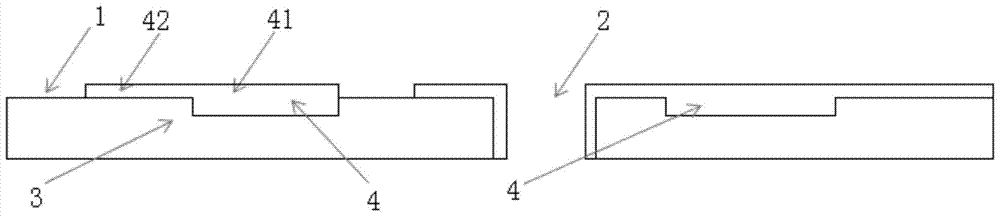

[0067] A kind of 1OZ / 3OZ high step copper circuit board (double panel) manufacturing method, according to Figure 4 The process flow shown proceeds as follows:

[0068] (1) Pre-process: Including cutting, drilling and other processes, it is produced according to the conventional process.

[0069] (2) Deep gong: Before work, measure the flatness of the operation table to control the operation table at a horizontal height, and detect the warpage of the circuit board that requires deep gong to ensure that the warpage does not exceed 0.4%. Then place the inner layer of the multi-layer board horizontally, use a gong machine to deep-drill the inner layer according to the preset thick copper line direction and depth, and drill thick copper line slots on the circuit board that are consistent with the preset thick copper line direction.

[0070] The gong machine is placed on a platform made of cement and cushioning materials after the ground has been compacted, and the weight of the g...

Embodiment 3

[0092] The manufacturing method of the high-step copper circuit board of the present embodiment is basically the same as the manufacturing method of Embodiment 1, the difference is that:

[0093] The circuit board is a 1OZ / 12OZ high-level copper circuit board.

[0094] (3) Copper sinking: the process parameters of the degumming process are: KMnO 4 The concentration is 50g / L, and the degumming rate is 0.4g / cm 2 .

[0095] The copper sinking process parameters are: 33°C, Cu2 + The concentration is 2.4g / L, the concentration of HCHO is 4.5g / L, the concentration of NaOH is 13g / L, and the copper precipitation rate is 0.10g / cm 2 .

[0096] (6) Embedded copper: use the following copper paste screen printing process to embed copper in the thick copper line groove: fill the conductive copper paste into the thick copper line groove by screen printing, the specific process is: the screen printing angle is 5 -15 degrees, the pressure of the scraper is 20-30Kg / cm 2 , The screen printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com