High precision acoustic senseing device and acoustic camera using microphone array

A technology of microphone array and induction device, applied in frequency/directional characteristic device, TV, color TV components and other directions, can solve problems such as high price and complex structure, improve product quality, improve production cost, and achieve lightweight The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

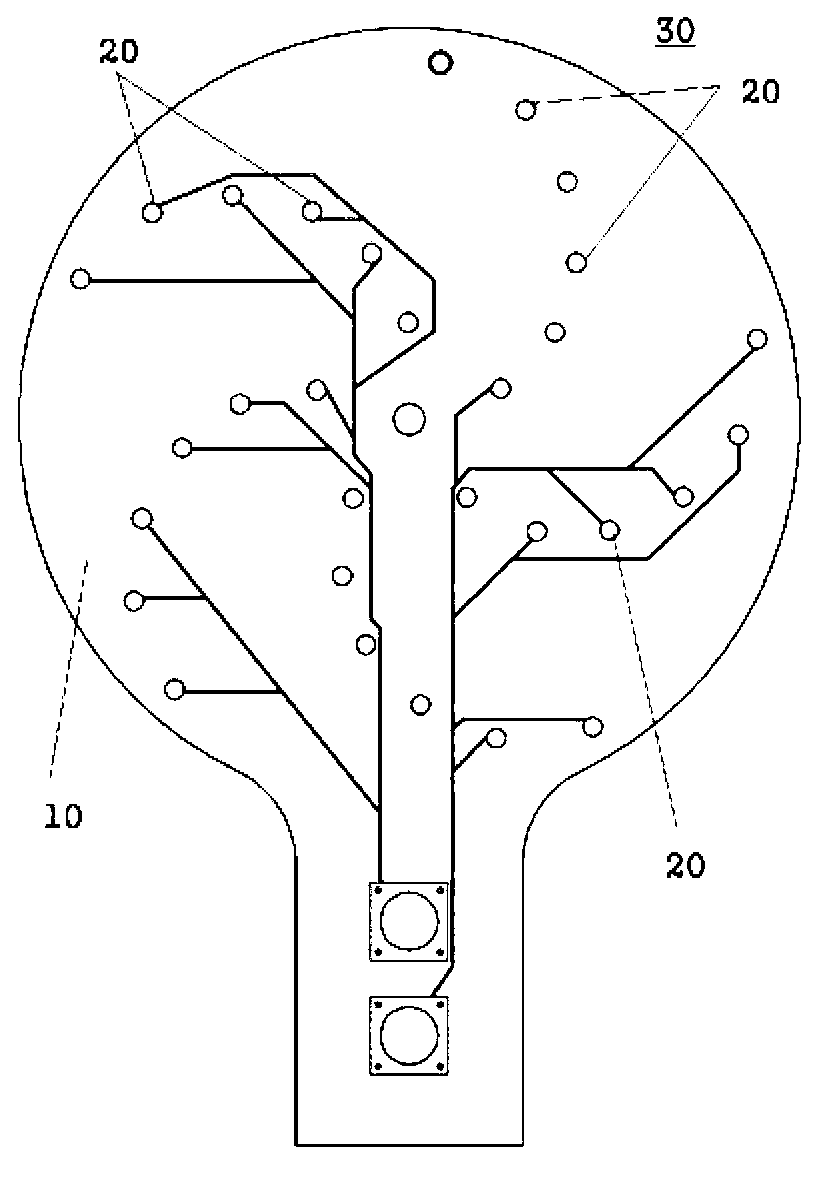

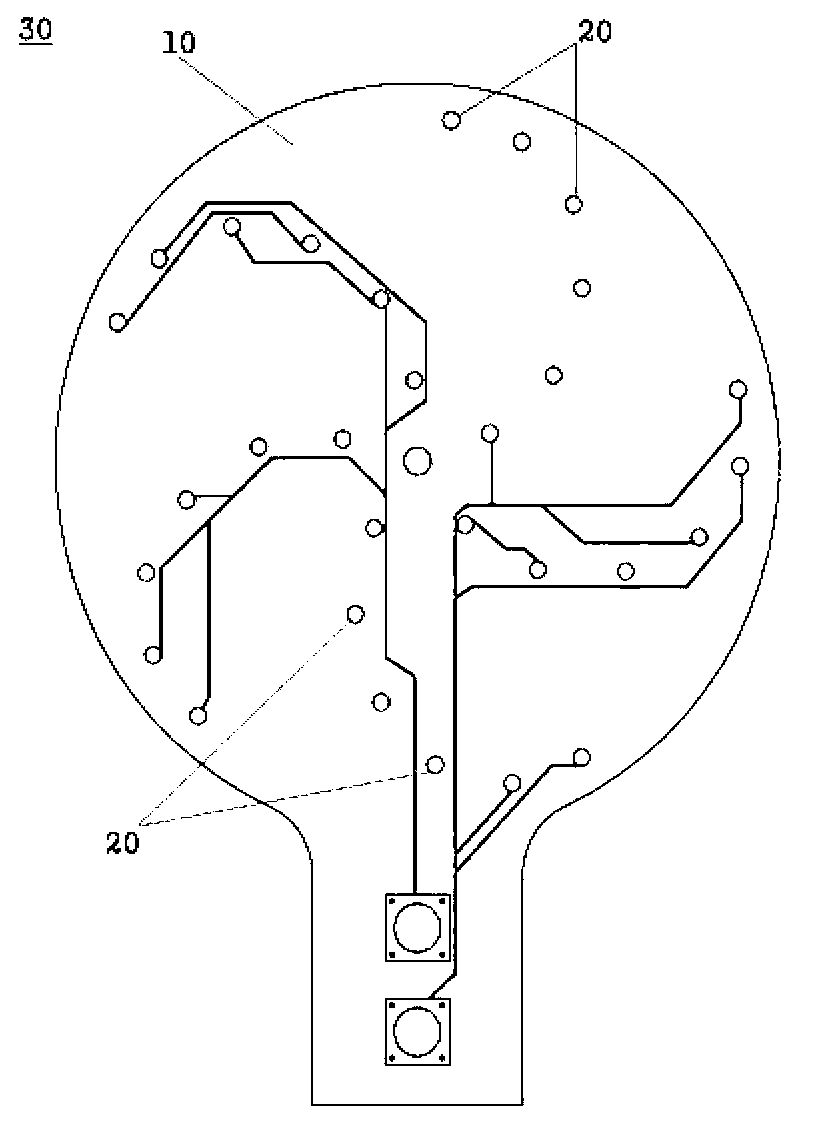

[0029] The high-precision acoustic sensing device and the audio camera using the MEMS microphone array will be described in detail below with reference to the accompanying drawings. Such as Figure 1a to Figure 1b As shown, the high-precision acoustic induction device using a MEMS microphone array according to the embodiment of the present invention is composed of a plurality of MEMS microphones 10 arranged on a printed circuit board 20 . There are circuits inside the printed circuit board 20, and the circuits include, for example, a power supply circuit for supplying power or an output circuit for outputting an electric signal generated from an induced acoustic signal.

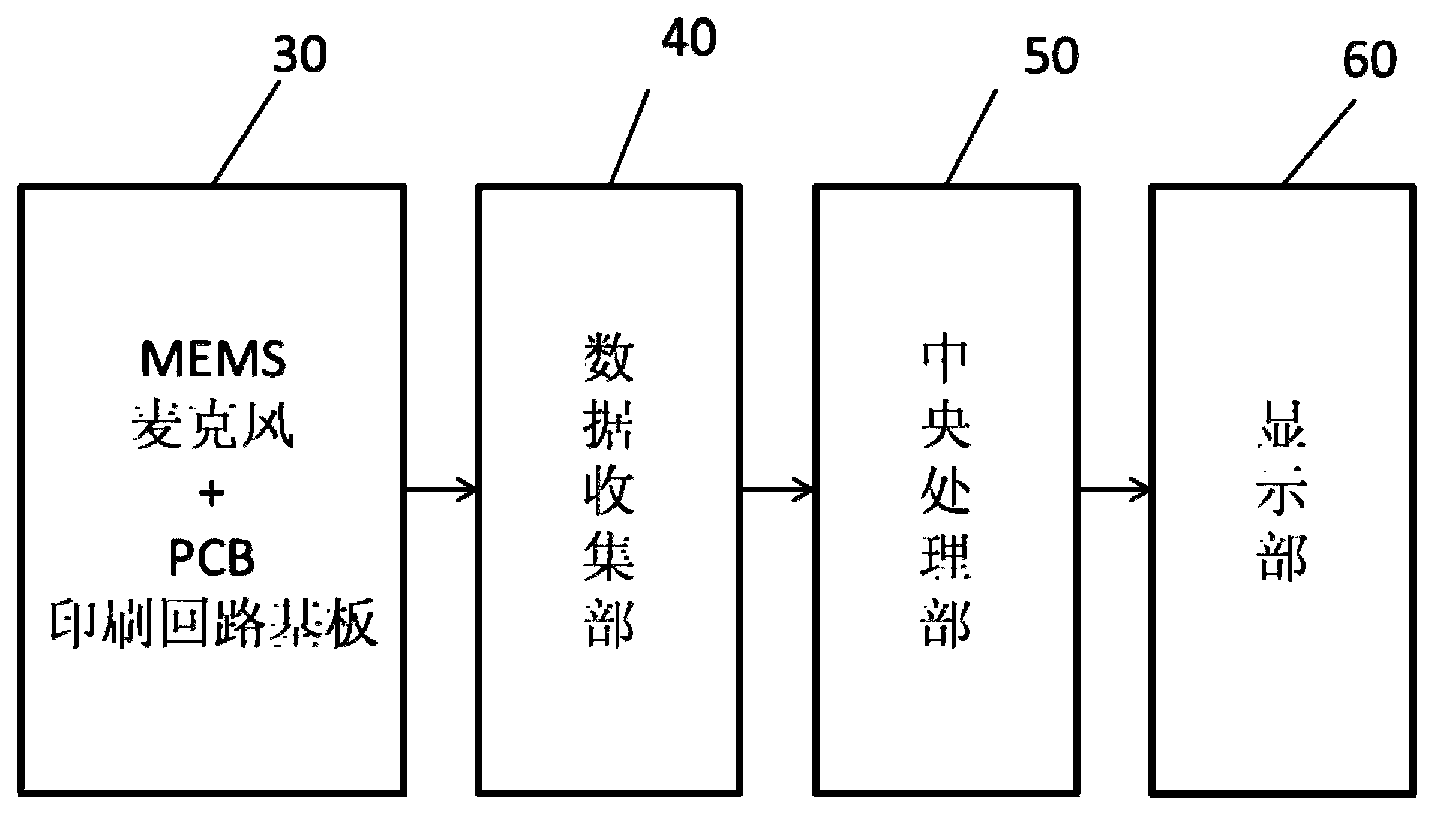

[0030] The electric signal related to the output sound is sent to the data collection unit 40 through the output circuit, and the signal amplifier is passed in the middle to increase the magnitude of the electric signal. The signal amplifier may be provided separately, or integrated with the printed circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com