MEMS (micro-electro-mechanical system) microphone and method for manufacturing same

一种制作方法、麦克风的技术,应用在麦克风结构协会、半导体静电换能器、扩音器等方向,能够解决后腔体积小、MEMS麦克风前腔体积大等问题,达到改善频响高频部分、提升产品灵敏度、改善总谐波失真的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

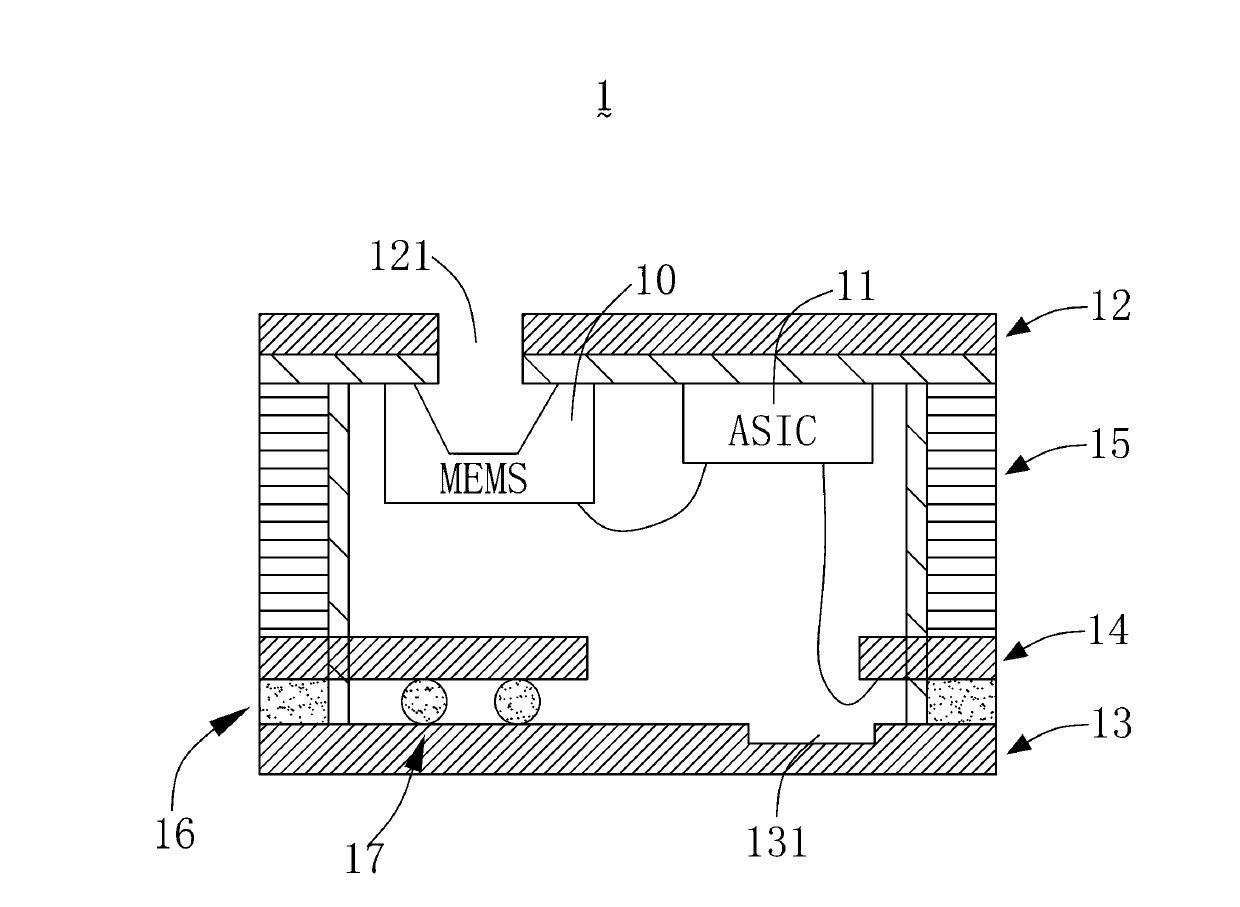

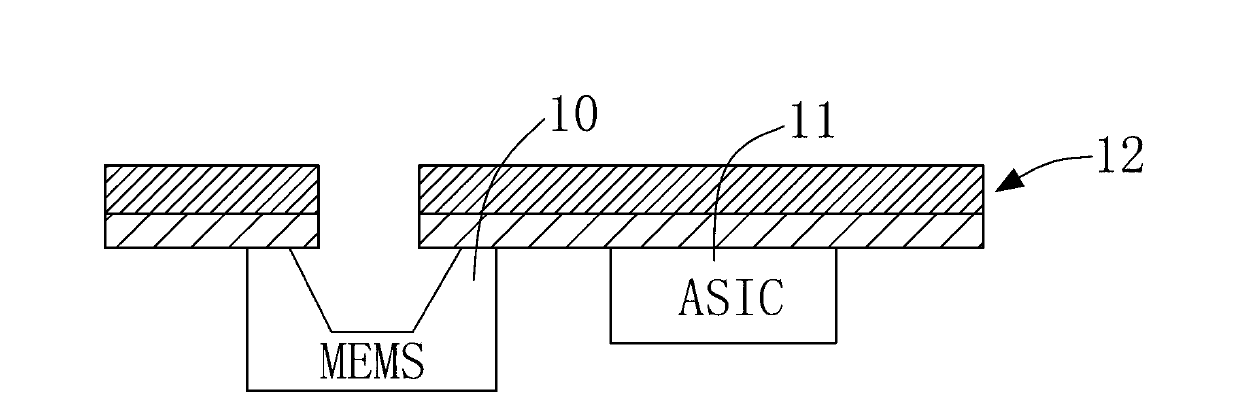

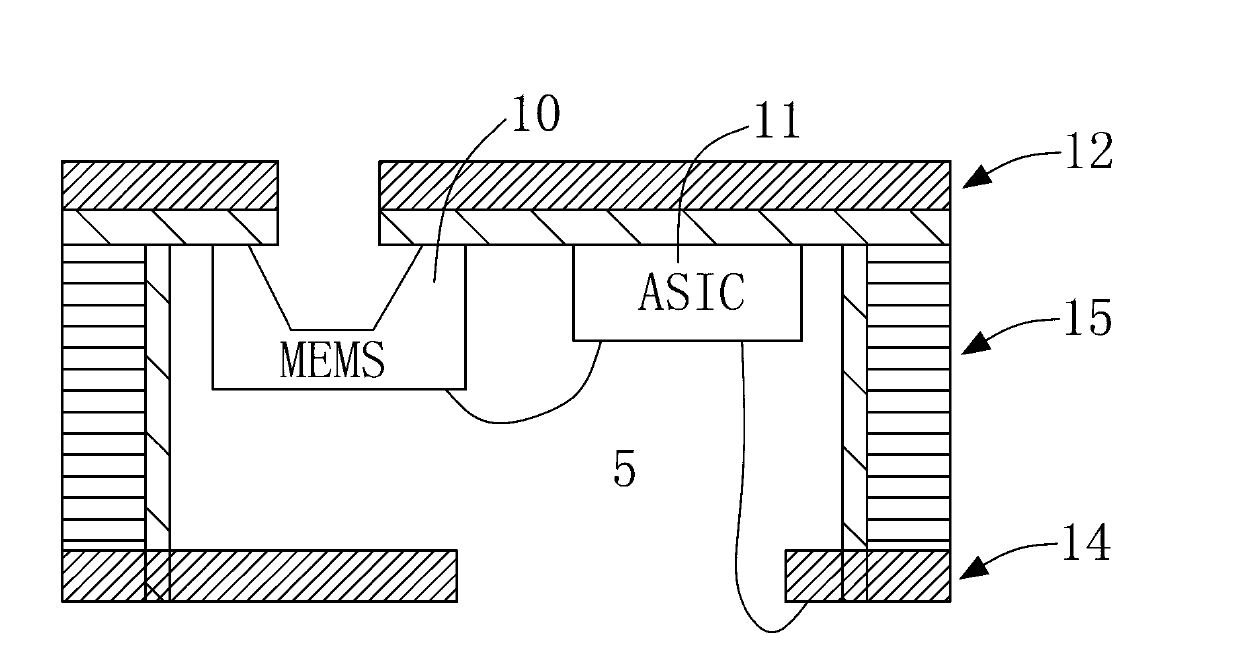

[0021] see figure 1 , figure 1 It is a side-view structure diagram of an embodiment of the MEMS microphone of the present invention, and the MEMS microphone 1 includes a MEMS (Micro-Electro-Mechanical-System Microphone, micro-electro-mechanical system microphone) chip 10, an ASIC (Application Specific IC, application-specific integrated circuit) chip 11 , the first circuit board substrate 12 , the second circuit board substrate 13 , the third circuit board substrate 14 and the frame substrate 15 .

[0022] Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com