Light-emitting diode (LED) driving circuit based on parallel switch control

A technology of LED drive and switch control, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of high circuit cost, high power factor, service life impact, etc., to reduce LED volume, improve power factor, The effect of reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

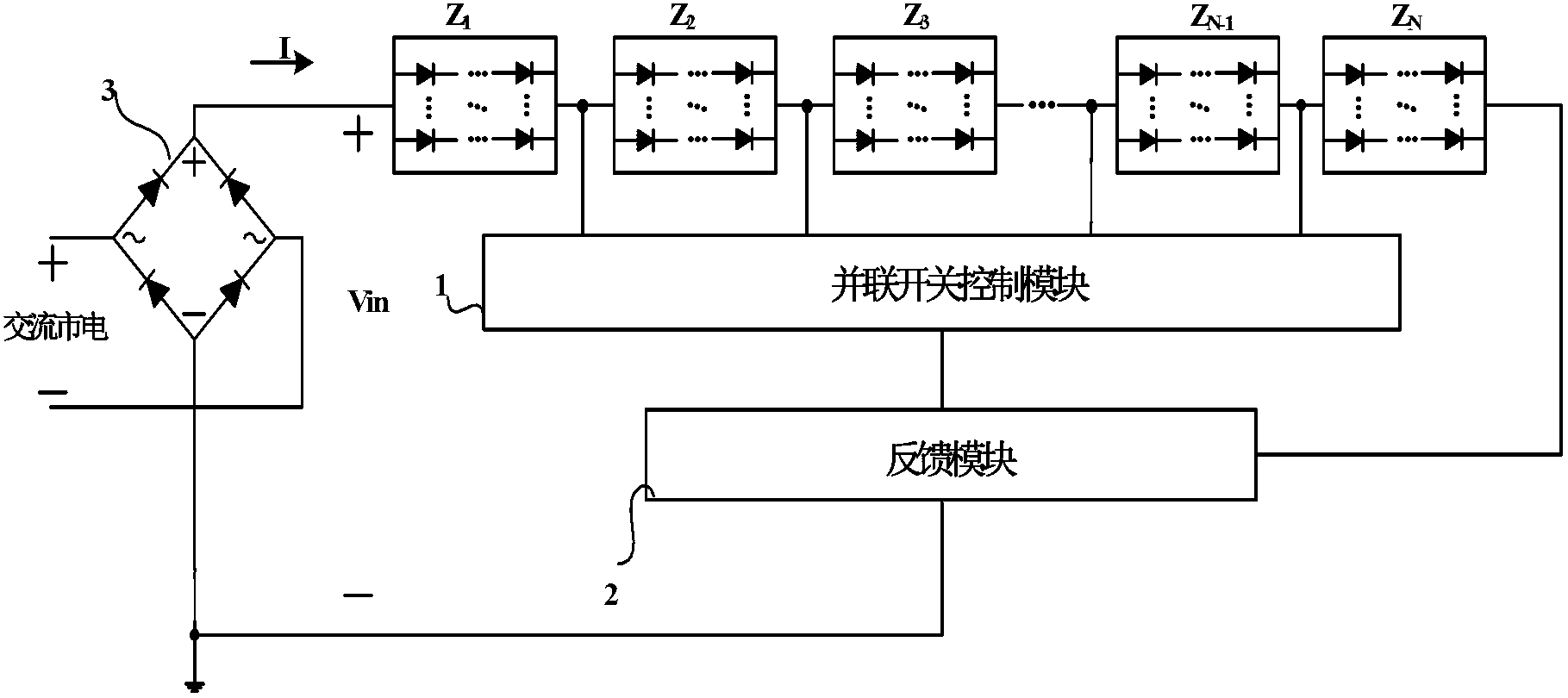

[0042] refer to Figure 4 , the LED drive circuit of the present invention includes a parallel high-voltage switch control module 1, a feedback module 2, a rectifier bridge 3 and N load networks Z 1 ~ Z N , N≥1.

[0043] The N load network Z 1 ~ Z N , a single group is connected in series between the rectifier bridge 3 and the feedback module 2, wherein each load network is composed of L strings of light-emitting diodes connected in parallel, and each string of light-emitting diodes is composed of M light-emitting diodes in series, 1≤ M×N<100, L≥1.

[0044] The parallel high-voltage switch control module 1 consists of N-1 high-voltage switch devices S 1 ~S N-1 constitute; these high-voltage switching devices S 1 ~S N-1 The output terminal b is connected, and connected to the feedback module 2 and the Nth load network Z N The common terminal of the first high-voltage switching device S 1 The input a of is connected to the first load network Z 1 with a second load net...

Embodiment 2

[0051] refer to Figure 5 , the LED drive circuit of the present invention includes a parallel high-voltage switch control module 1, a feedback module 2, a rectifier bridge 3 and N load networks Z 1 ~ Z N , N≥1.

[0052] The N load network Z 1 ~ Z N , a single group is connected in series between the rectifier bridge 3 and the feedback module 2, wherein each load network is composed of L strings of light-emitting diodes connected in parallel, and each string of light-emitting diodes is composed of M light-emitting diodes in series, 1≤ M×N<100, L≥1.

[0053] The parallel high-voltage switch control module 1 consists of N-1 high-voltage switch devices S 1 ~S N-1 constitute; these high-voltage switching devices S 1 ~S N-1 The output terminals b of are respectively connected to the first N-1 resistors R of the feedback module 2 1 ~R N-1 ; The first high-voltage switching device S 1 The input a of is connected to the first load network Z 1 with a second load network Z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com