Cutting device for metal fine tube of high-precision silicon sensor

A cutting device and sensor technology, applied in the field of machinery, can solve the problems of silicon chip circuit short circuit, easy to pollute silicon chip, etc., and achieve the effects of prolonging service life, convenient adjustment, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

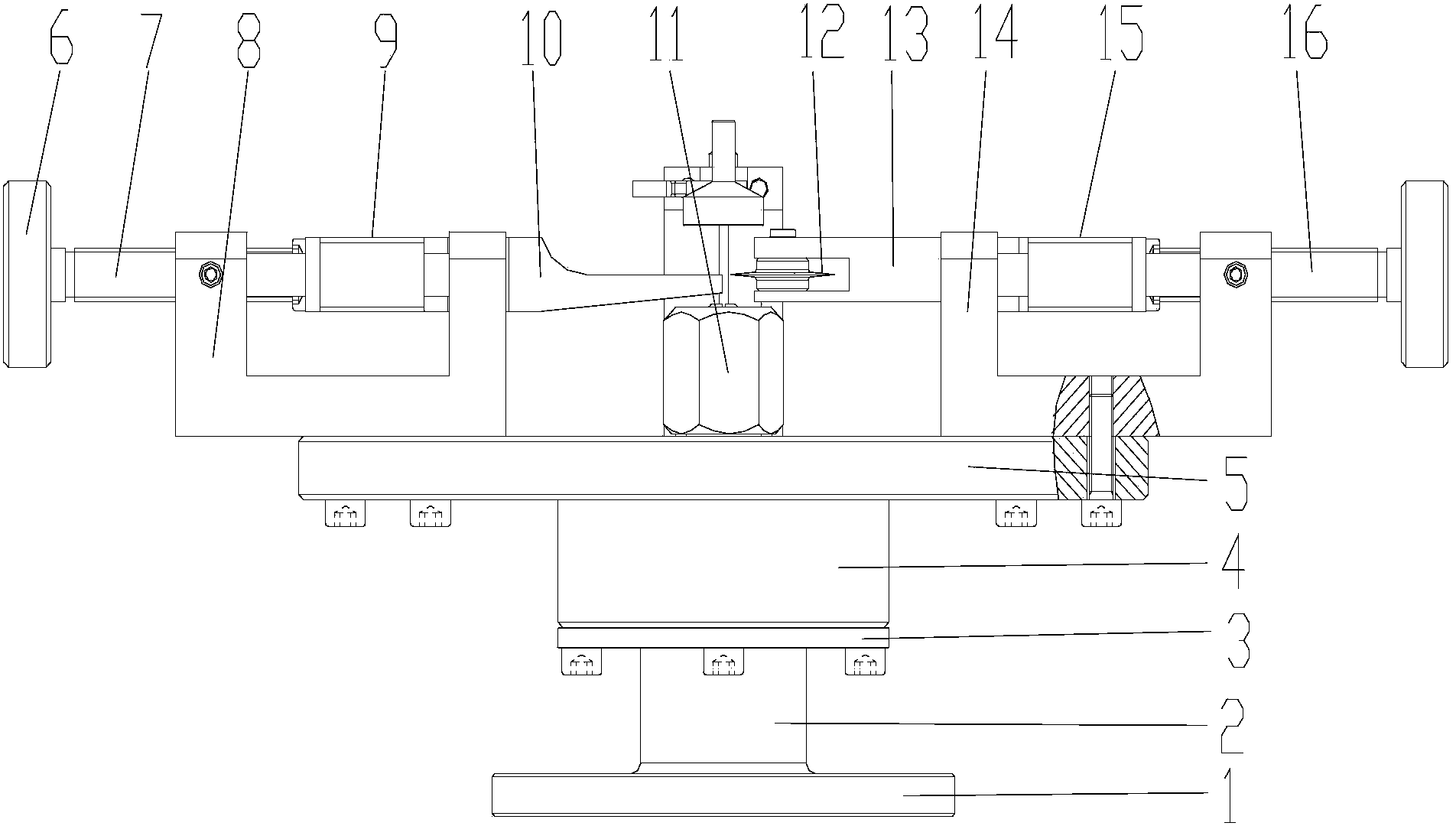

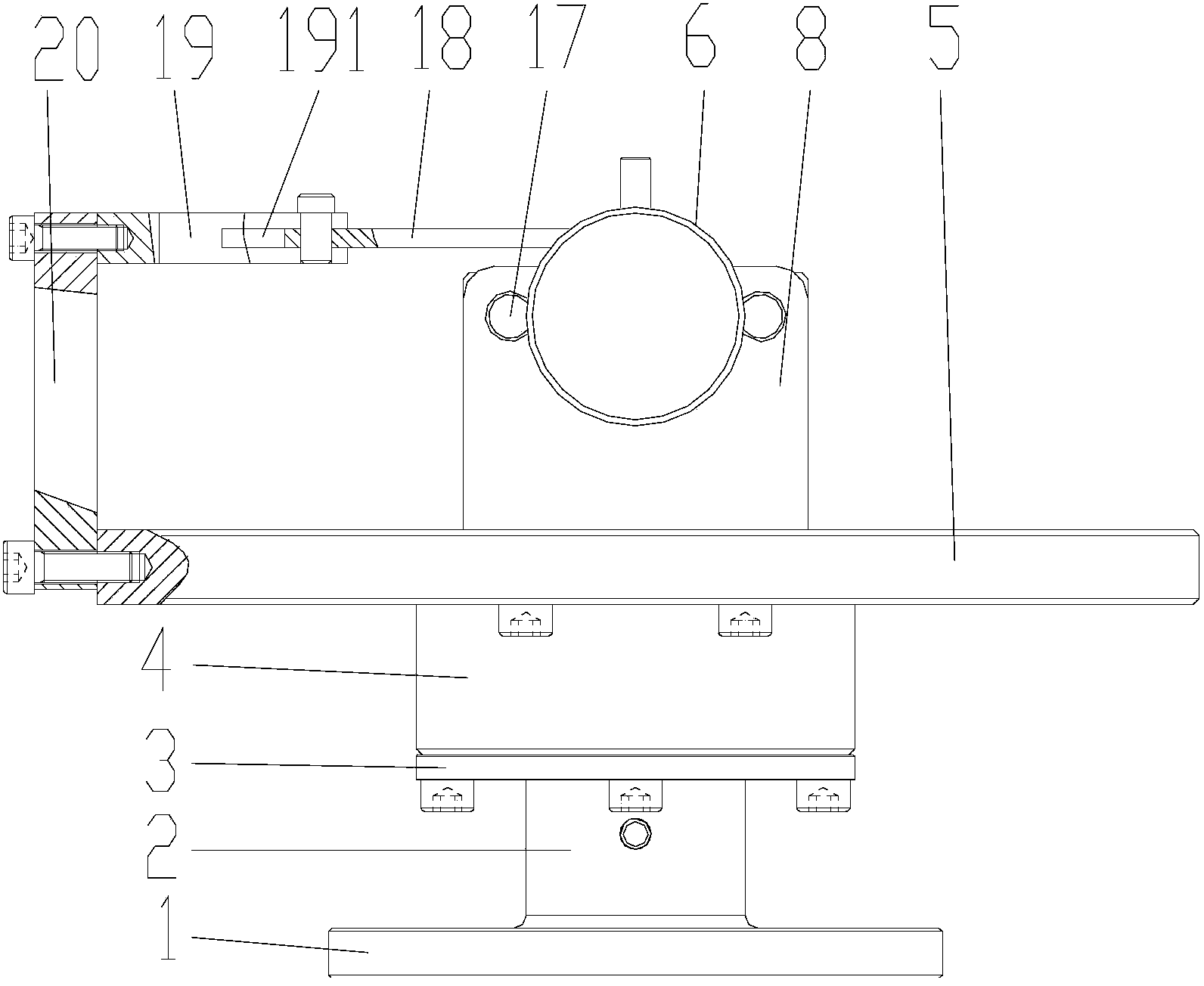

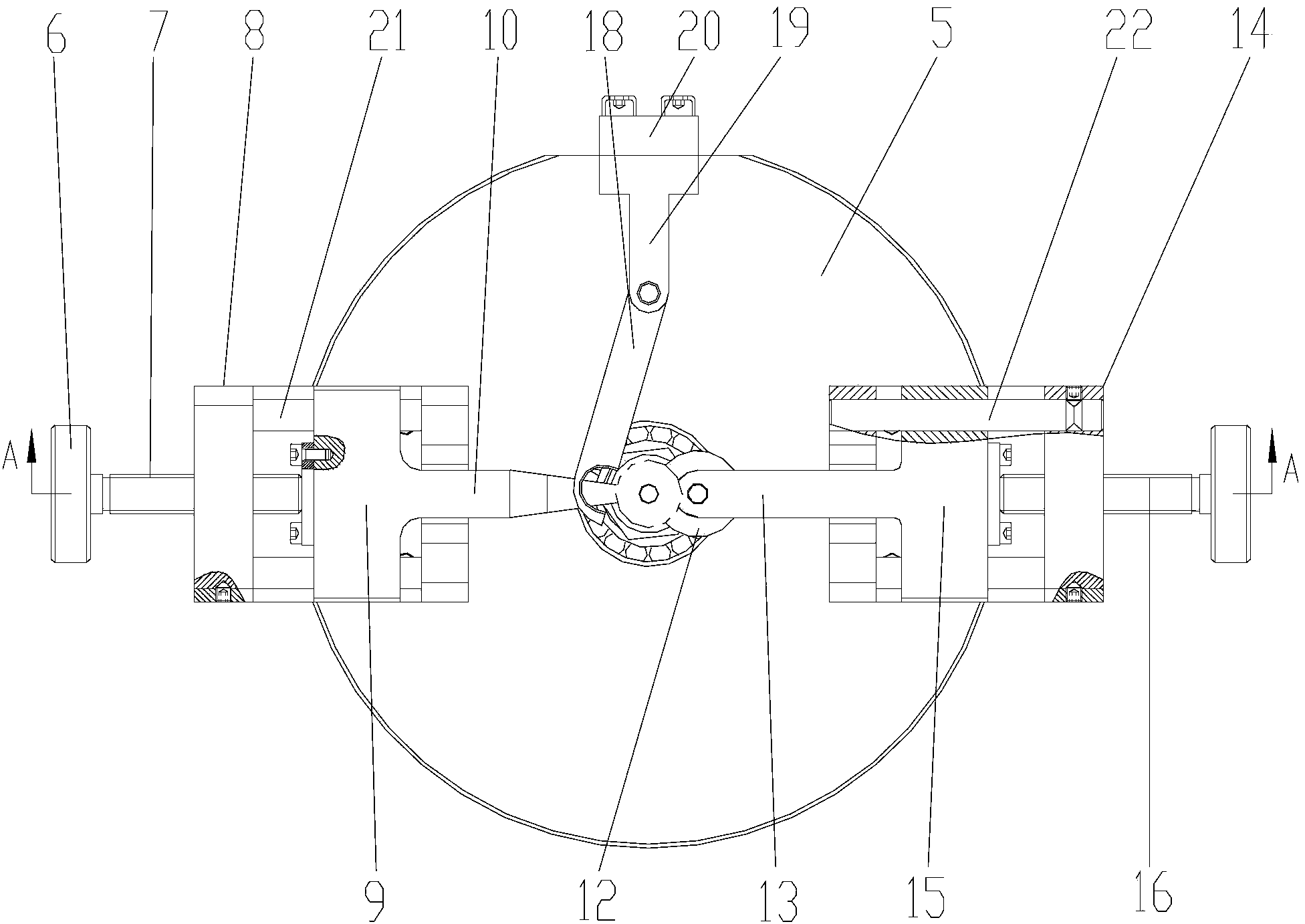

[0018] figure 1 It is a schematic diagram of the main structure of the present invention, figure 2 It is a schematic diagram of the left view structure of the present invention, image 3 It is a schematic diagram of the top view structure of the present invention, Figure 4 for image 3 The schematic diagram of the cross-sectional structure of A-A in the middle, as shown in the figure, a high-precision silicon sensor metal thin tube cutting device provided by the present invention includes a cutting assembly for cutting the metal thin The clamping assembly, the rotating disk 5 for fixing and installing the cutting assembly and the clamping assembly, the positioning assembly for clamping and positioning the thin metal tube, and the mounting seat for fixing and installing the positioning assembly, the rotating disk is covered by the The positioning assembly and can rotate around the positioning assembly, the cutting assembly and the clamping assembly are symmetrically provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com