Method for solidifying protective clip in carbon/silicon carbide brake disc

A protection clip, silicon carbide technology, applied in the direction of brake parts, etc., can solve problems such as failure to meet the requirements of design drawings, damage to stressed parts, damage to steel clips and brake discs, etc., to avoid difficulties in riveting and reduce stress. Uniform and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

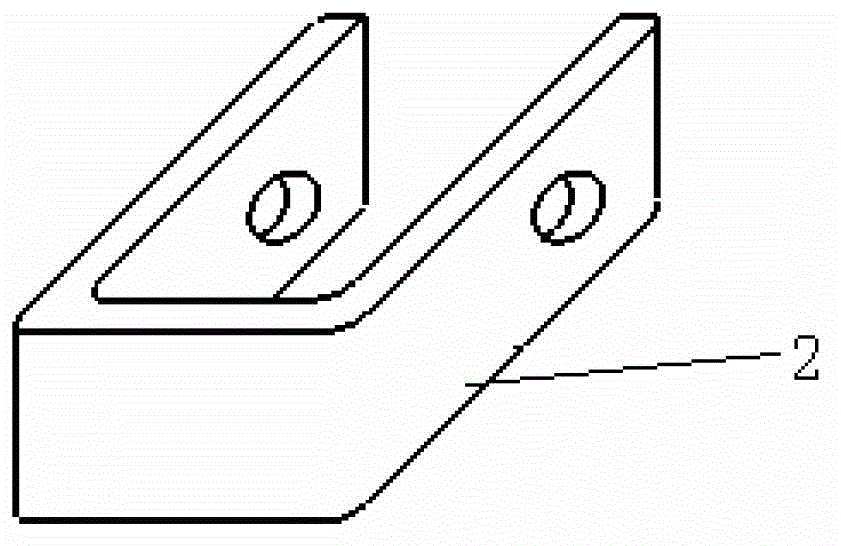

[0029] This example is a method of curing a protective clip in a carbon / silicon carbide brake rotor. The brake disc is a dynamic brake disc, that is, a dynamic disc. The structure of the protective clip is a common U-shaped structure made of carbon / silicon carbide.

[0030] This embodiment includes the following steps:

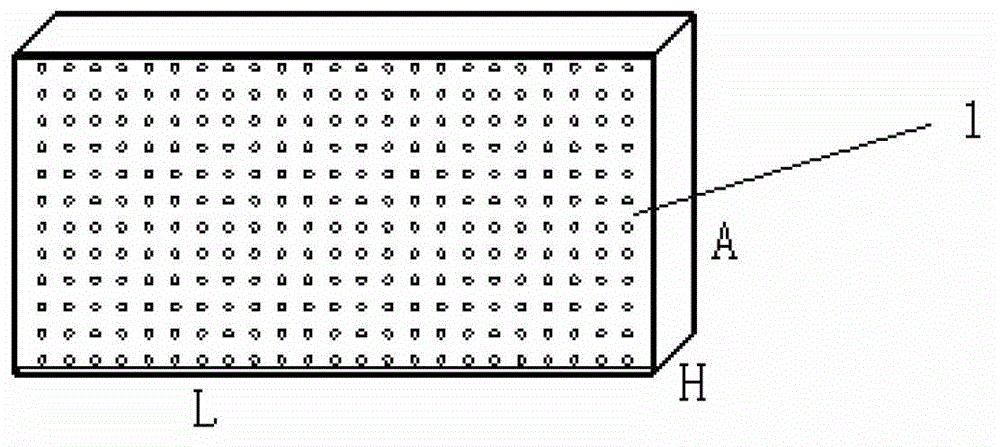

[0031] Step 1, making the tire mold of the protective clip. Described tire mold is made of graphite, is cuboid, and its external dimension is the same as the size of the U-shaped opening of the protective clip made, and its length is determined according to the quantity of required protective clips, and the width is the depth of the U-shaped opening of the protective clip. 3 times. The height b of the tire mold is equal to the thickness of the keyboard. There are through holes on the surface of the tire mold, and the distance between the centers of adjacent through holes is 5-10 mm; the diameter of the through holes is 3-5 mm. The chamfer of the long side...

Embodiment 2

[0042] This example is a method of curing a protective clip in a carbon / silicon carbide brake rotor. The brake disc is a carbon / carbon static brake disc, that is, a static disc. The structure of the protective clip is a common U-shaped structure made of carbon / silicon carbide.

[0043] This embodiment includes the following steps:

[0044] Step 1, making the tire mold of the protective clip. Described tire mold is made of graphite, is cuboid, and its external dimension is the same as the size of the U-shaped opening of the protective clip made, and its length is determined according to the quantity of required protective clips, and the width is the depth of the U-shaped opening of the protective clip. 3 times. The height b of the tire mold is equal to the thickness of the static disk key. There are through holes on the surface of the tire mold, and the distance between the centers of adjacent through holes is 5-10 mm; the diameter of the through holes is 3-5 mm. The chamf...

Embodiment 3

[0055] This example is a method of curing a protective clip in a carbon / silicon carbide brake rotor. The brake disc is a dynamic brake disc, that is, a dynamic disc. The structure of the protective clip is a common U-shaped structure made of carbon / silicon carbide.

[0056] This embodiment includes the following steps:

[0057] Step 1, making the tire mold of the protective clip. Described tire mold is made of graphite, is cuboid, and its external dimension is the same as the size of the U-shaped opening of the protective clip made, and its length is determined according to the quantity of required protective clips, and the width is the depth of the U-shaped opening of the protective clip. 3 times. The height b of the tire mold is equal to the thickness of the keyboard. There are through holes on the surface of the tire mold, and the distance between the centers of adjacent through holes is 5-10 mm; the diameter of the through holes is 3-5 mm. The chamfer of the long side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com