Parallel compressor selection and configuration method for preventing compressor from being frequently started up and shut down

A compressor and DC frequency conversion technology, which is applied to compressors, refrigerators, lighting and heating equipment, etc., can solve the problems of wasting the output potential of compressor capacity, large cooling capacity of compressors, frequent start and stop of compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

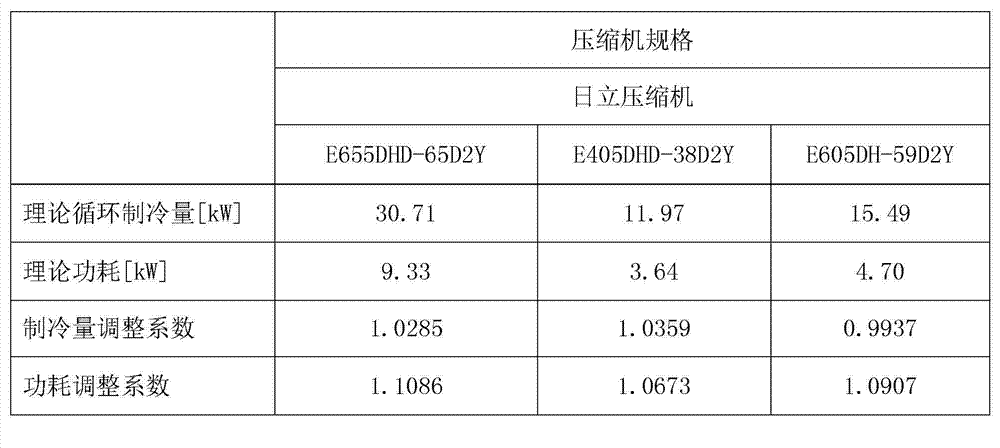

[0089] Specific embodiment 1: Take the selection of a 16-horsepower DC variable-frequency multi-connected outdoor unit compressor as an example to illustrate

[0090] Step 1: Calculate the calculation adjustment coefficient for the conversion of the performance parameters of the compressor under the nominal working condition to the design working condition

[0091] (1) Determine the displacement, operating frequency, cooling capacity, power consumption and energy efficiency ratio of the compressor under nominal working conditions and nominal working conditions from the compressor specifications provided by the compressor manufacturer. The nominal working conditions of the compressor include condensation Temperature, condensation subcooling, evaporation temperature, evaporation superheat, the specific values are shown in Table 1 and Table 2;

[0092] Table 1:

[0093]

[0094] Table 2:

[0095]

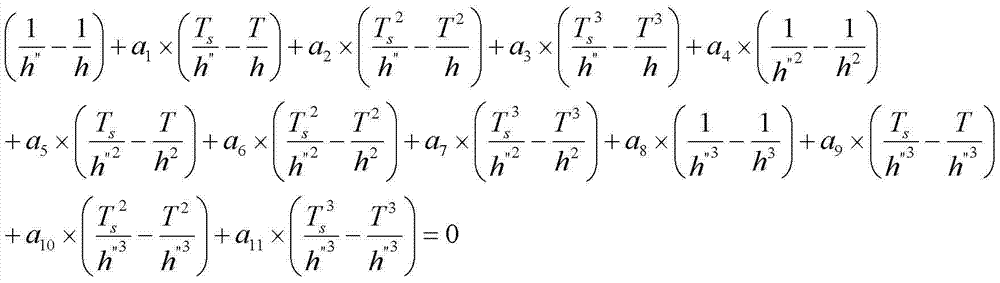

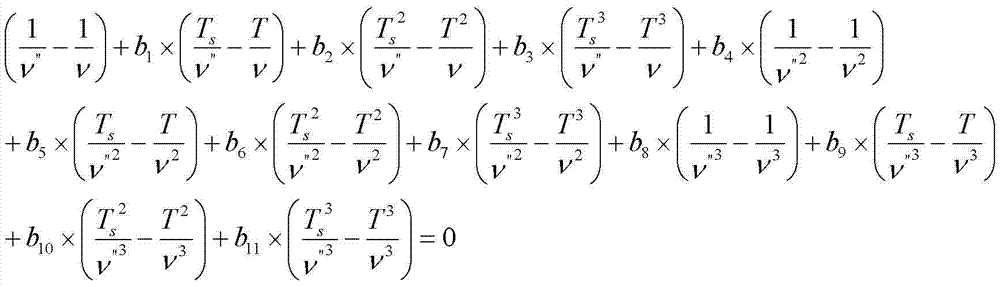

[0096] (2) According to the evaporation temperature, evaporation superhe...

specific Embodiment 2

[0137] Specific embodiment 2: Take the selection of 12-horsepower DC frequency conversion multi-connected outdoor unit compressor as an example to illustrate

[0138] Step 1, Step 2, and Step 3 are the same as those in Example 1, and will not be repeated here.

[0139] Step 4: Determine the operating frequency range of the DC inverter compressor

[0140] DC inverter compressor E405DHD-38D2Y operating frequency range (20rps~90rps);

[0141] Step 5: Optional Parallel Fixed Frequency Compressor

[0142] Parallel fixed-frequency compressor selection method, the selection principle is that the cooling capacity of the fixed-frequency compressor cannot be greater than the maximum cooling capacity at the maximum operating frequency of the DC inverter compressor.

[0143] (1) According to the actual cooling capacity Q of the DC inverter compressor in step 3 (3) INV-act (f) and the allowable operating frequency range f of the DC inverter compressor in step 4 min ≤f≤f max , calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com