Method utilizing isothermy relaxation current method for evaluating insulated overhead conductor

An overhead insulated wire and isothermal relaxation current technology, applied in the field of testing, can solve the problem of inability to quickly analyze the insulation state of overhead insulated wires, and achieve the effects of light structure, easy installation and portability, and simple test process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

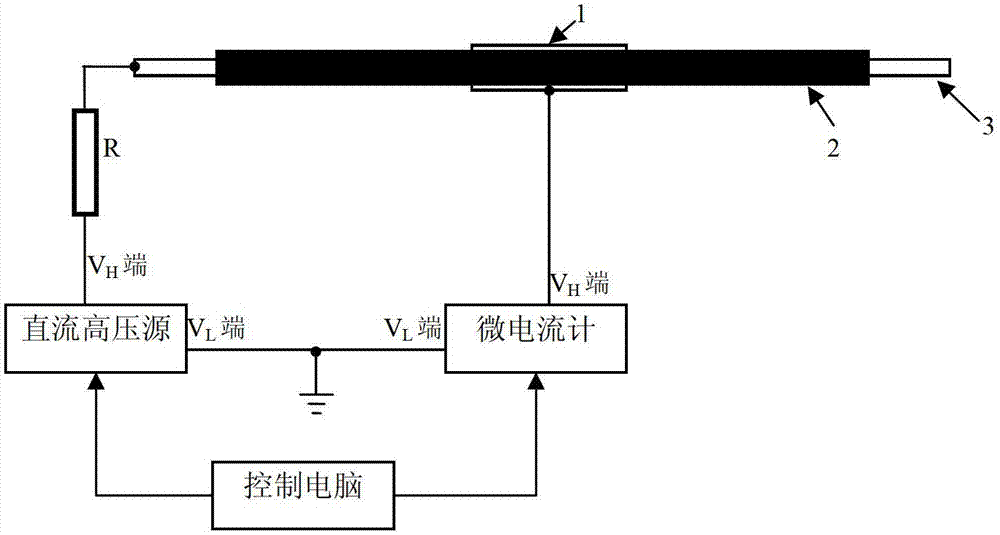

[0019] figure 1 Among them, this test system is mainly for the measurement of overhead insulated wires. The hardware system is mainly composed of a digitally controlled DC high voltage source, a digitally controlled micro ammeter and a control computer. The voltage output range of the DC high voltage source is 0-1kV, and the measuring range of the micro ammeter is 1pA-1nA. Through the control software in the control computer, the output voltage of the DC high voltage source can be digitally controlled, and the current data measured by the micro ammeter can be transmitted to the control computer in real time, which is convenient for data analysis.

[0020] During the test, first set a layer of aluminum foil as a test electrode on the outside of an overhead insulated wire; the high-voltage output end of the DC high-voltage source is connected to the core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com