Patterned substrate and light emitting diode (LED) chip used for LED inverted-assembly structure

A patterned substrate and flip-chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of hemispherical pattern parameter selection that has not yet formed a system, and achieve improved internal quantum efficiency, luminous flux, and improved luminous flux. The effect of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

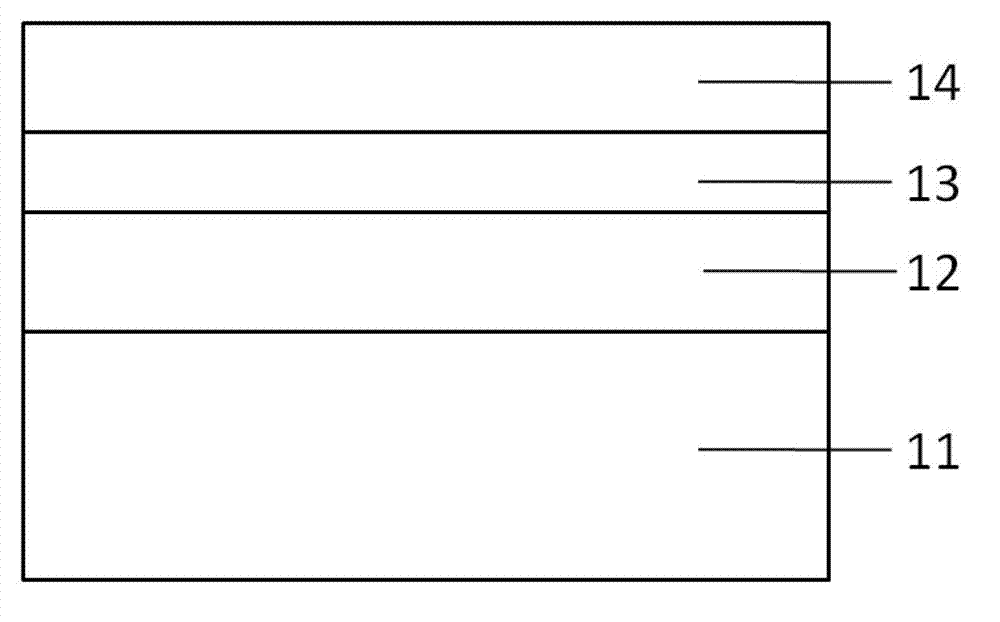

[0030] figure 1 Be the schematic diagram of the LED chip of this embodiment, as figure 1 As shown, it consists of a patterned sapphire substrate 11, an N-type GaN layer 12, an MQW quantum well layer 13, and a P-type GaN layer 14 arranged in sequence.

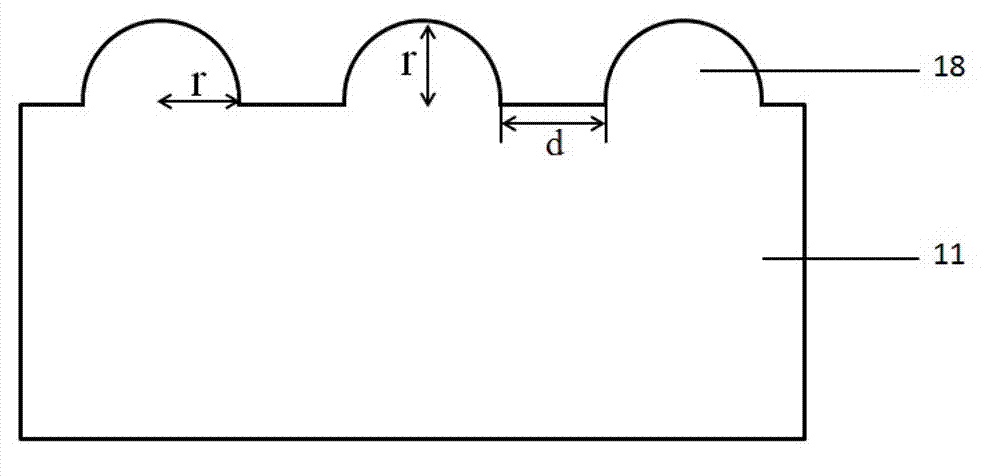

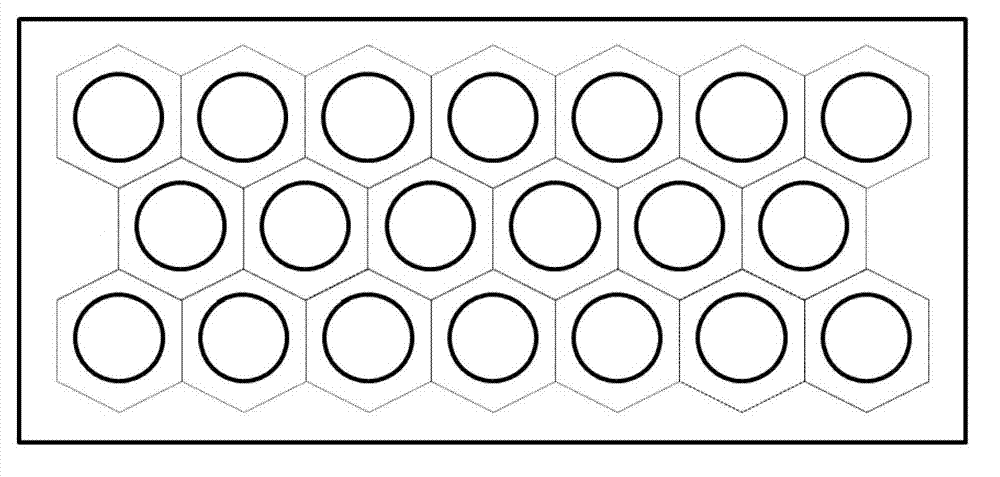

[0031] like figure 2 As shown, in the patterned substrate of the LED chip of the present embodiment, the pattern of the substrate is composed of a plurality of hemispheres 18 of the same shape arranged on the surface of the substrate; the height of the hemisphere is equal to the radius r of the bottom surface of the corresponding hemisphere; the adjacent hemisphere The edge spacing d is 0.7 times of the radius r of the bottom surface of the hemisphere; the radius r of the bottom surface of the hemisphere is 2 μm in the present embodiment; image 3 The hexagonal arrangement shown.

[0032] Figure 4 It is a schematic diagram of applying the patterned substrate to the LED flip-chip structure in this embodiment. Each layer in...

Embodiment 2

[0034] The patterned substrate of the LED chip of the present embodiment has a refractive index of 1.1, and the pattern of the substrate is composed of a plurality of hemispheres of the same shape arranged on the surface of the substrate; the height of the hemisphere and the radius r of the bottom surface of the corresponding hemisphere Equal; the edge spacing d of adjacent hemispheres is 0.9 times of the base radius r of the hemisphere; the base radius r of the hemisphere is 2.8 μ m in the present embodiment; Figure 5 The rectangular arrangement shown.

Embodiment 3

[0036] The patterned substrate of the LED chip of the present embodiment has a refractive index of 2, and the pattern of the substrate is composed of a plurality of hemispheres of the same shape arranged on the surface of the substrate; the height of each hemisphere is the same as the bottom surface of the corresponding hemisphere The radii r are equal; the distance d between the edges of adjacent hemispheres is 1.0 times the radius of the bottom surface of the hemisphere; the radius r of the bottom surface of the hemisphere in this embodiment is 3.0 μm; the multiple hemispheres with the same shape are arranged in a rectangular manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com