Non-aqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in secondary batteries, batteries, battery electrodes, etc., can solve problems such as ignition, achieve high output, high capacity, good charge-discharge cycle characteristics, and improve the effect of supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

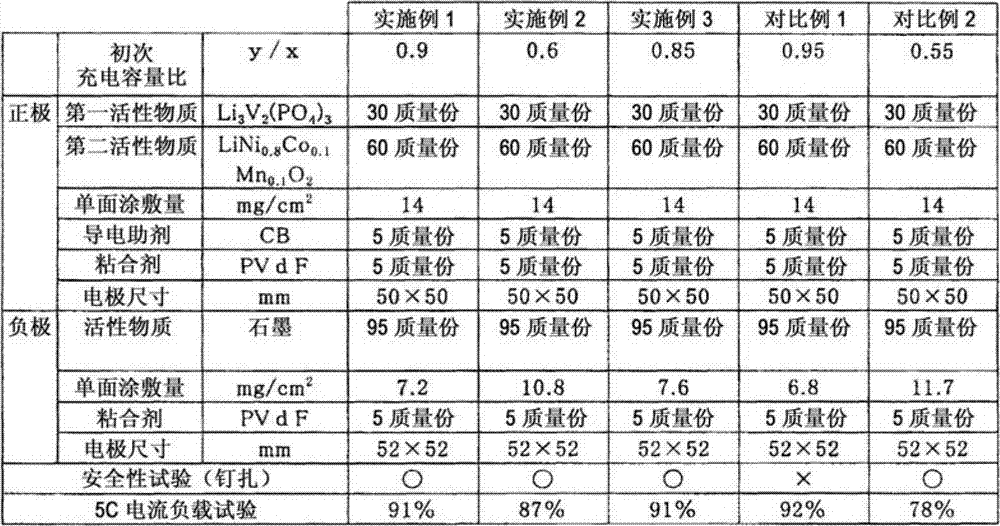

Embodiment 1)

[0059] (1) Production of positive electrode

[0060] The following materials are used for the positive electrode composite material layer:

[0061] The first active material (Li 3 V 2 (PO 4 ) 3 ): 30 parts by mass

[0062] The second active material (LiNi 0.8 co 0.1 mn 0.1 o 2 ): 60 parts by mass

[0063] Binder (polyvinylidene fluoride (PVdF): 5 parts by mass

[0064] Conductive material (carbon black): 5 parts by mass

[0065] Solvent (N-methyl-2-pyrrolidone (NMP)): 100 parts by mass

[0066] Mix to obtain positive electrode slurry. The positive electrode slurry was applied on a positive electrode current collector of aluminum foil (thickness: 30 μm) and dried to form a positive electrode composite material layer on the positive electrode current collector. The coating amount (per side) of the positive electrode composite material layer is 14mg / cm 2 . The uncoated part of 10×10 mm was reserved as the tab for lead wire connection, and the coated part (the part ...

Embodiment 2)

[0080] Changed the coating amount (per side) of the negative electrode composite material layer to 10.6mg / cm 2 , so that the initial charge capacity of the negative electrode per unit area is set to x[mAh / cm 2 ], set the initial charge capacity of the positive electrode per unit area as y[mAh / cm 2 ], except that the relationship between x and y was y / x=0.6, all the conditions were the same as in Example 1, and batteries were produced and evaluated. The capacity retention rate was 87%. In the pinning safety test, the battery did not experience abnormal heating or fire.

Embodiment 3)

[0082] Changed the coating amount (per side) of the negative electrode composite material layer to 7.6mg / cm 2 , so that the initial charge capacity of the negative electrode per unit area is set to x[mAh / cm 2 ], set the initial charge capacity of the positive electrode per unit area as y[mAh / cm 2 ], except that the relationship between x and y was y / x=0.85, all the conditions were the same as in Example 1, and a battery was produced and evaluated. The capacity retention rate was 91%. In the pinning safety test, the battery did not experience abnormal heating or fire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com