Water-cooling power module of medium-voltage high-power frequency changer

A power module and high-power technology, which is applied in the direction of converting AC power input to DC power output, output power conversion device, and structural parts of conversion equipment, etc., which can solve the problems that cannot meet the limitations of front maintenance, ship use environment, and ship application fields , large volume of high-power inverters, etc., to achieve fast and reliable combination and separation, compact structure, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

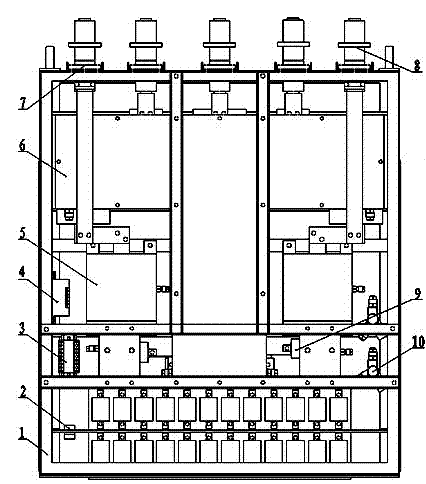

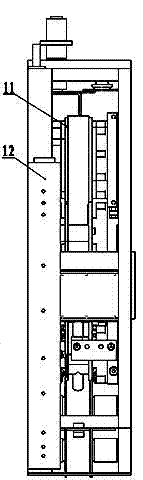

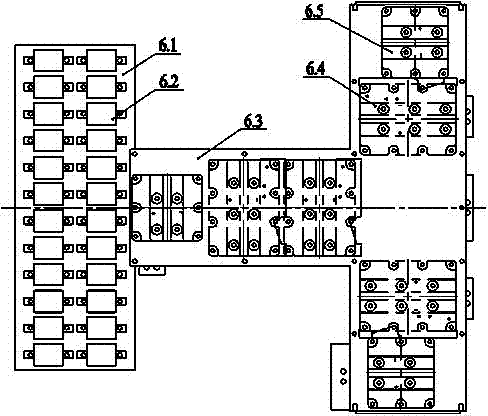

[0029] A medium-voltage high-power inverter water-cooled power module, which includes a module frame 1, a positive power component 6, a negative power component 11, two water-cooled inductors 5, two water-cooled resistors 9, and five sets to provide channels for the input and output current of the module The high-voltage and high-current connector, the power module 4, the power transfer terminal 3, the photoelectric connector 2, and the slide rail 12; the side of the high-voltage and high-current connector is the rear, and the opposite side is the front, Each set of connectors consists of a plug 8 and a socket 7; the socket 7 of the connector is directly fixed on the vertical beam at the rear of the frame 1, and is connected with the water-cooled inductor 5 and the positive and negative power components 6, 11 by a soft busbar; The plug 8 is directly fixed on the crossbeam of the cabinet, and is connected with the DC side and output side busbars by soft busbars; the positive powe...

Embodiment 2

[0031] The difference from the above-mentioned embodiment 1 is that, further, the two water-cooled inductors 5 and the two water-cooled resistors 9 are installed in the middle of the module, and are respectively installed in two T-shaped water-cooled heat dissipation plates in the power module symmetrically with respect to the center line of the power module. The water-cooling inductor 5 is fixed at the bottom of the module, and the water-cooling resistor 9 is hoisted on the top of the module; the power module 4 and the power transfer terminal 3 that provide driving power for the IGBT inside the power module are installed in the left front frame of the module On; the photoelectric connector 2 is installed on the left front frame 1 of the module, and the external control signal and power are transmitted to the IGBT drive board and the power module through it.

Embodiment 3

[0033] The difference from the foregoing embodiment 2 is that, further, the positive and negative power components 6, 11 are fixed to the frame 1 by bolts through the T-shaped water-cooled heat sink in the power component; the two water-cooled inductors 5 It is a high-voltage current-limiting water-cooled inductor, and the two water-cooled resistors 9 are high-voltage low-inductance current-limiting water-cooled resistors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com