Micro-bubble generation device

A micro-bubble generation and micro-bubble technology, which is applied in water aeration, sustainable biological treatment, mixers, etc., can solve the problems of less bubbles and increased energy consumption of water supply pumps, and achieve good processing and assembly process, and easy operation Simple and convenient, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

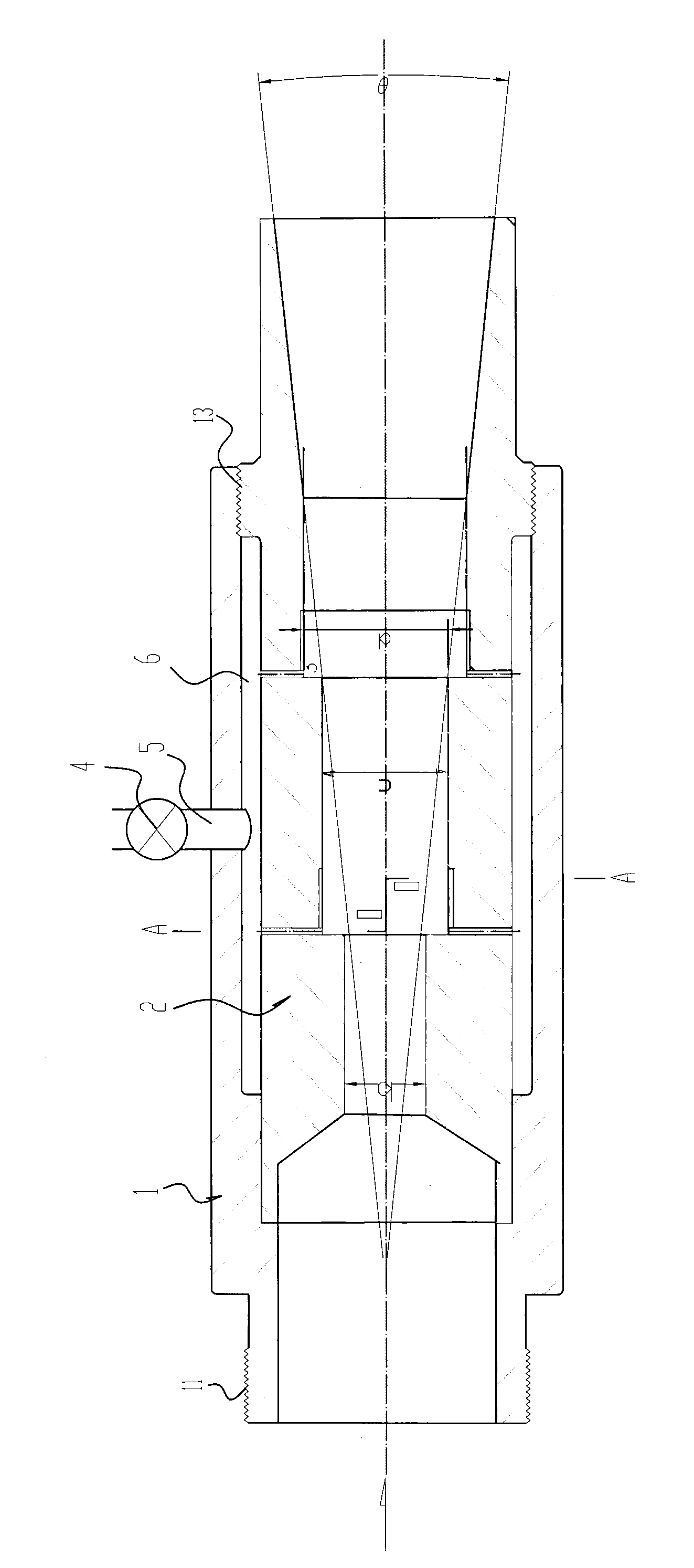

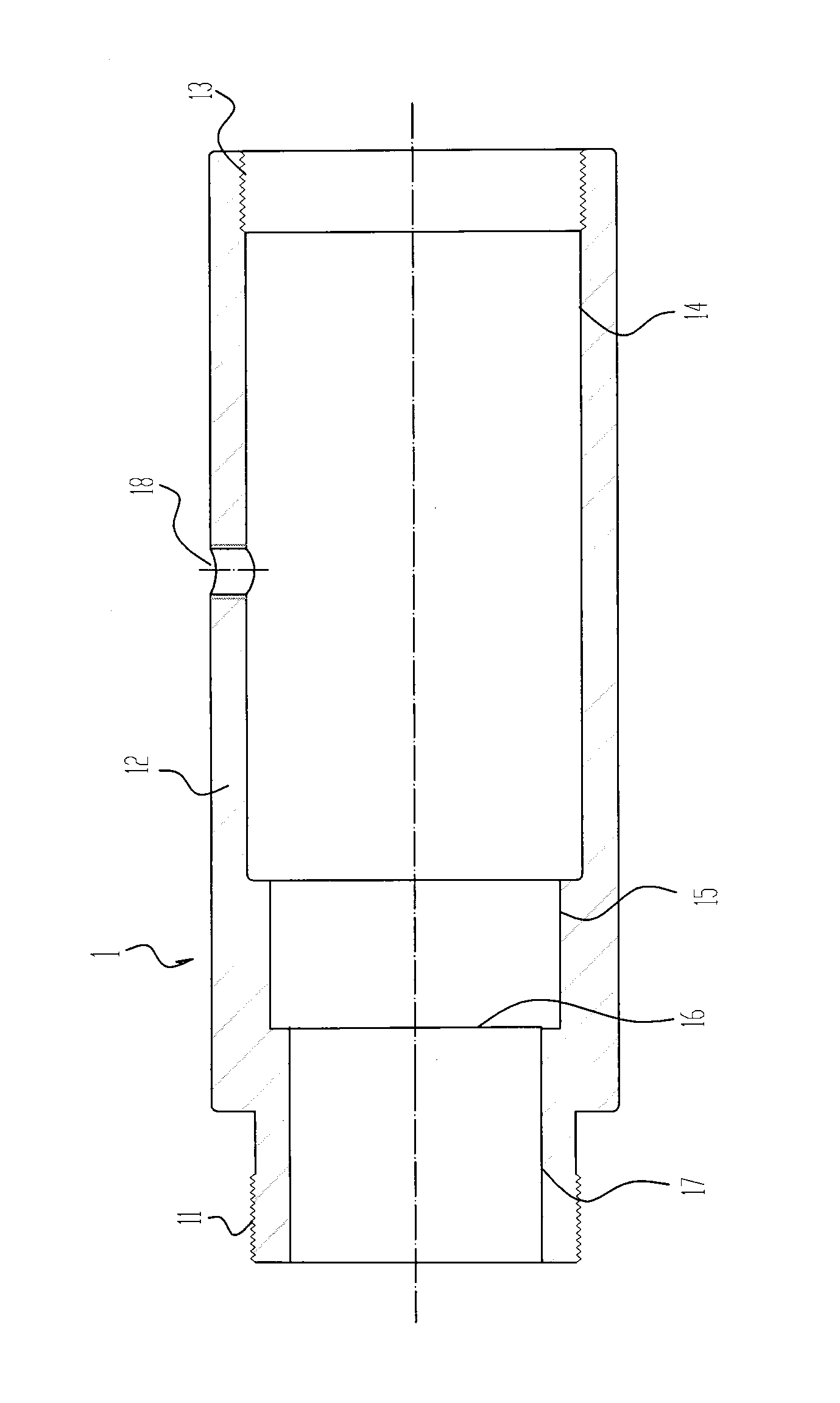

[0031] Embodiment 1, referring to the accompanying drawings listed above. The micro-bubble generating device of the embodiment of the present invention includes a core tube 2 and an outer casing 1, and the water flow direction is set to flow in from the left direction and flow out from the right side;

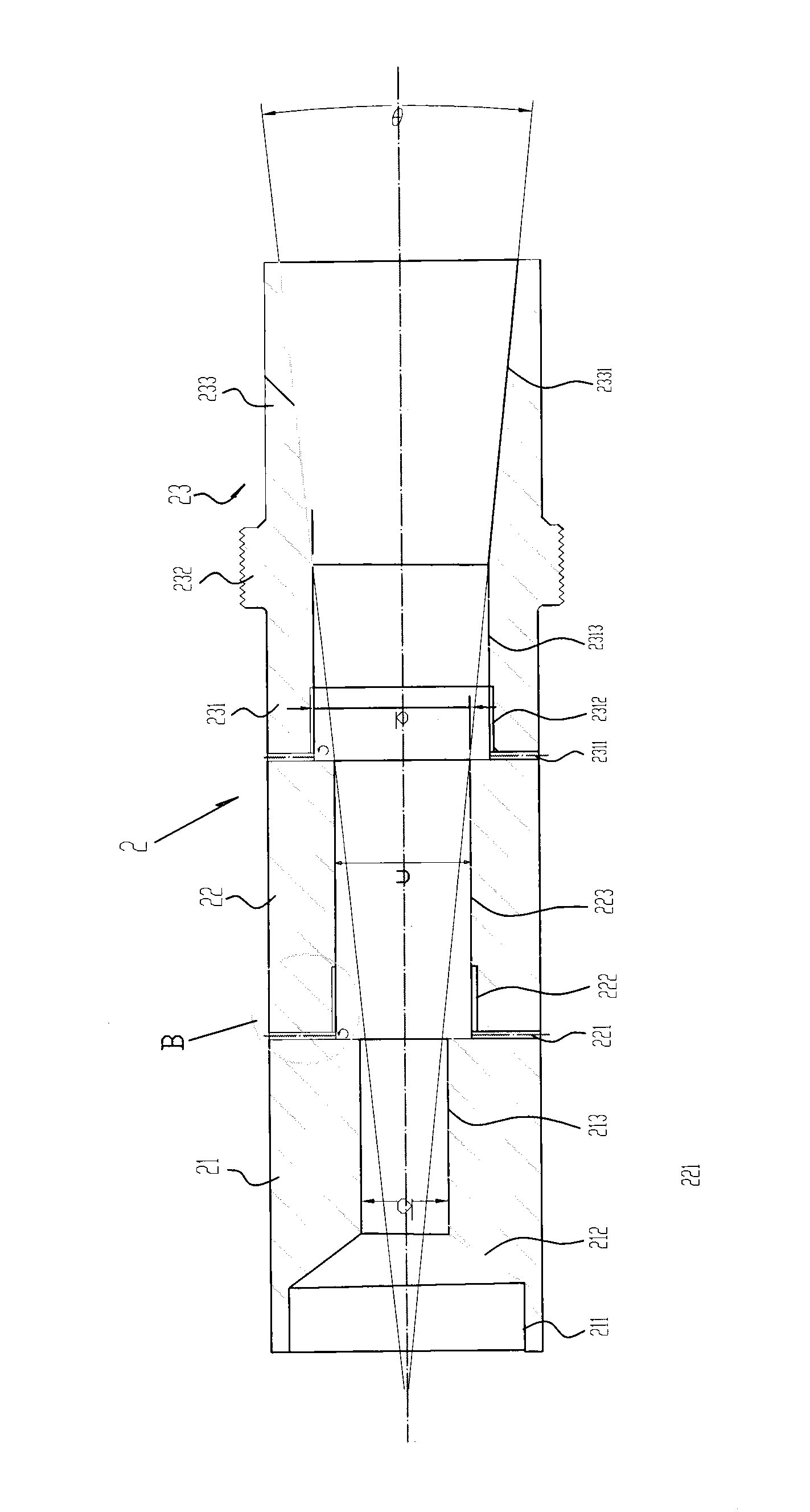

[0032] Wherein the core tube 2 (see image 3 ) includes the following pipe sections located on the same axial line:

[0033] A water suction pipe section 21, the water suction pipe section 21 includes a large cylindrical tube 211, a horn-shaped tube 212 and a small cylindrical tube 213 arranged in sequence from the water inlet direction to the water outlet direction and connected to each other;

[0034] At least one micro-bubble generation pipe section I22, the micro-bubble generation pipe section I22 includes a cylindrical tube 223 with a diameter larger than the diameter of the small cylindrical tube 213 in the above-mentioned water suction pipe section, and also includes at...

Embodiment 2

[0040] Embodiment 2, see again figure 1 . This embodiment is a preferred embodiment. It differs from Embodiment 1 only in that the vent hole 18 on the outer sleeve 1 is a threaded hole that can be connected with the valve adapter 5; in addition,

[0041] A gas regulating valve 4 and a valve connecting pipe 5, the valve connecting pipe 5 is assembled in the aforementioned threaded hole 18, the gas regulating valve 4 is connected in the middle of the valve connecting pipe 5, and a circular ring is formed between the outer sleeve 1 and the core pipe 2 The airtight air chamber 6.

[0042] The number of microbubble generation pipe sections I 22 in the above two embodiments is preferably 2-3; the above-mentioned gas introduction holes 221, 2311 and cutting grooves 222, 2312 are uniformly distributed along the circumference and have the same number, such as Figure 4 The number of gas introduction holes shown is 6, and the number of cutting grooves is 8.

[0043] The cutting groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com