Method and die for preparing magnesium alloy board with multistage continuous corner cutting deformation

A shear deformation, magnesium alloy technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the limitation of the preparation of high-performance deformed magnesium alloy sheets, the low efficiency of high-performance deformed magnesium alloy sheets, and the difficulty in achieving grain size. Refinement of mutual coordination and other issues, to achieve excellent comprehensive mechanical properties, avoid equivalent strain reduction, and improve the effect of microstructure and grain orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

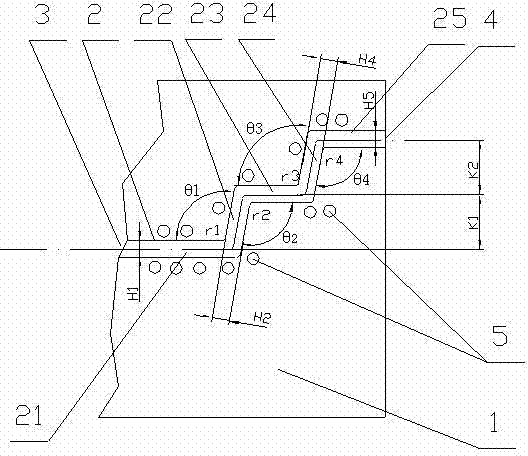

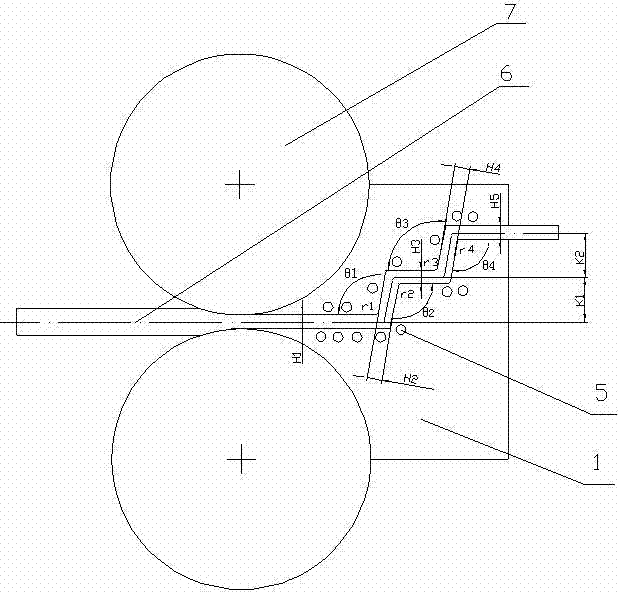

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0025] The method for preparing magnesium alloy plates by multi-stage continuous angular shear deformation of the present invention is characterized in that:

[0026] Install the multi-stage continuous angular shear deformation die at the exit of the double rolls of the twin-roll hot rolling mill. The channel openings set in the multi-stage continuous angular shear deformation die correspond to the exit of the double rolls of the hot rolling mill. After being rolled by two rolls, the plate directly enters the equal-height channel of the multi-stage continuous angular shear deformation mold; the friction force generated by the two-roll rolling deformation is used to provide power, so that the magnesium alloy plate to be processed passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com