Parameter control method for bend elbow type membrane assembling mechanism of injection molding machine

A technology of injection molding machine and toggle, which is applied in the field of parameter control of the toggle-type film lamination mechanism of injection molding machines. It can solve the problems of long invalid stroke, long dry cycle, and reduced speed, so as to improve the speed of mold opening and closing, and protect the mold well. Function, the effect of upgrading grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

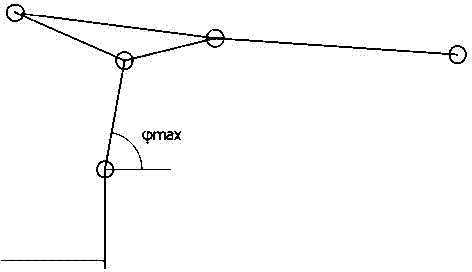

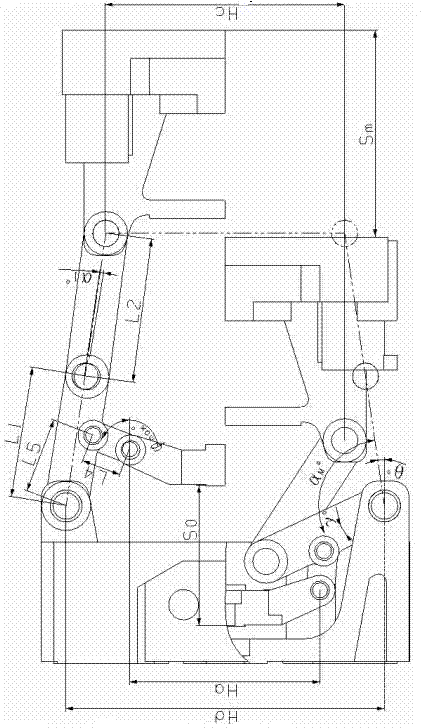

[0024] The parameter control method of the toggle-type film-closing mechanism of the injection molding machine includes setting the angle between the rear connecting rod and the straight state as α, the angle between the small connecting rod and the horizontal direction when the mold is clamped to the bottom as φ, and the speed curve of the mechanism up and down. Height, template and initial speed ratio of oil speed, range setting of mold protection area and mold clamping area.

[0025] The angle between the rear connecting rod and the straight state is α. When the mode is locked to the bottom, in order to realize self-locking, the control minimum angle αI must be smaller than the critical angle αC. The calculation formula of αC is as follows: αC = X + Y -θ;

[0026] Setting: dR = 1.27*fcoef*fDPin / 2

[0027] X = arcsin(2* dR / L1);

[0028] Z = arcs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com