Method for improving bonding soundness of glass beads on glass bead screen

A technology of glass microbeads and glass microbeads, applied in chemical instruments and methods, glass/slag layered products, projection devices, etc., can solve the problems of glass microbeads being easily scraped off, bead falling, and high cost, and achieve good results And stabilize the projection effect, improve water resistance and humidity resistance, and improve the effect of high temperature creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

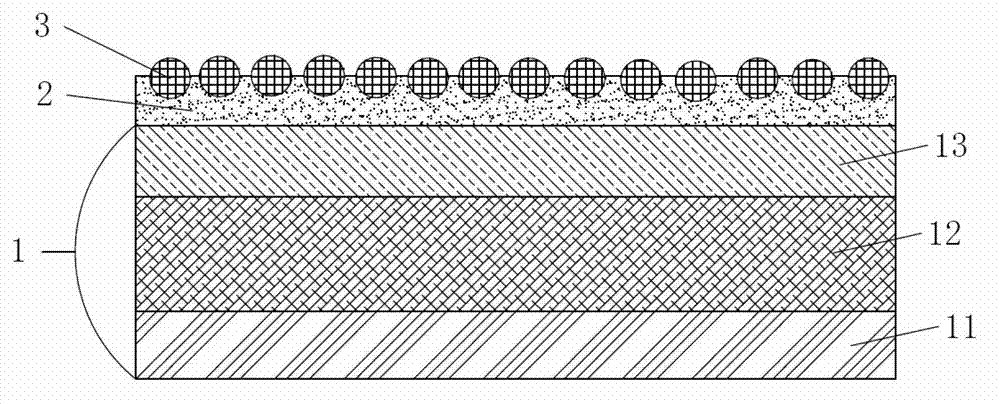

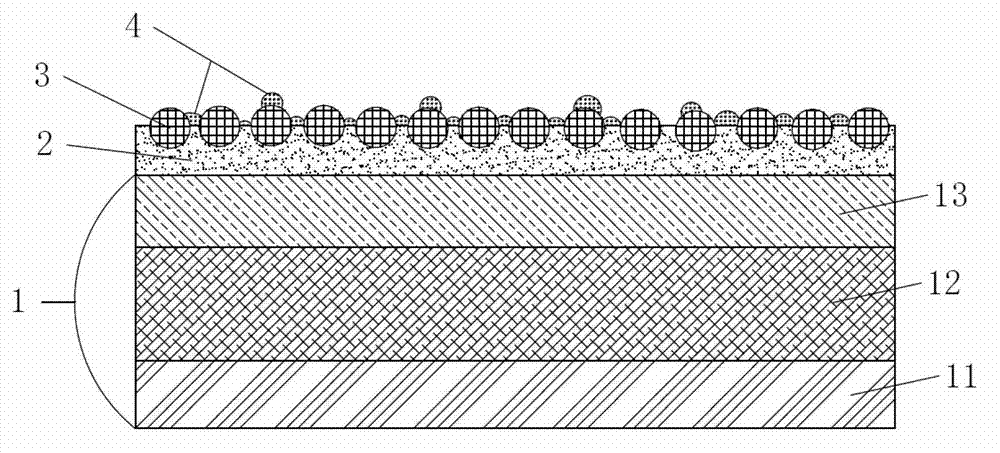

[0017] The present invention is a method for improving the bonding firmness of glass beads on a glass bead curtain. The method is specifically: uniformly coating a layer of white latex layer 2 on the upper surface of the curtain blank 1, and waiting for the white latex to evaporate naturally to 5~ When 80% dry, evenly sieve a layer of glass microspheres 3 on the white latex layer 2; The glass microbead curtain; wherein, the curtain blank 1 is laid with a layer of black curtain bottom 11, at least one layer of curtain base 12 and a layer of white curtain surface 13 from bottom to top, and the curtain base can be woven cloth or glass fiber cloth, Such as pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com