Optical glass

A kind of optical glass and glass technology, which is applied in the field of heavy lanthanum flint optical glass, which can solve the problems of difficult to obtain high-quality stripes, difficult molding, and low glass viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

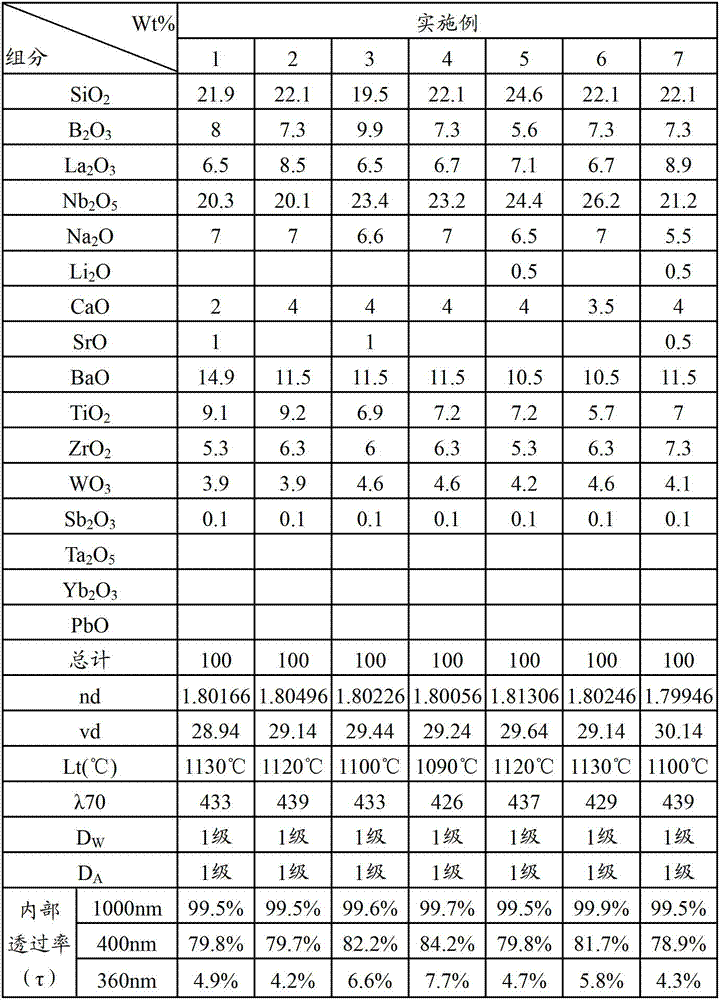

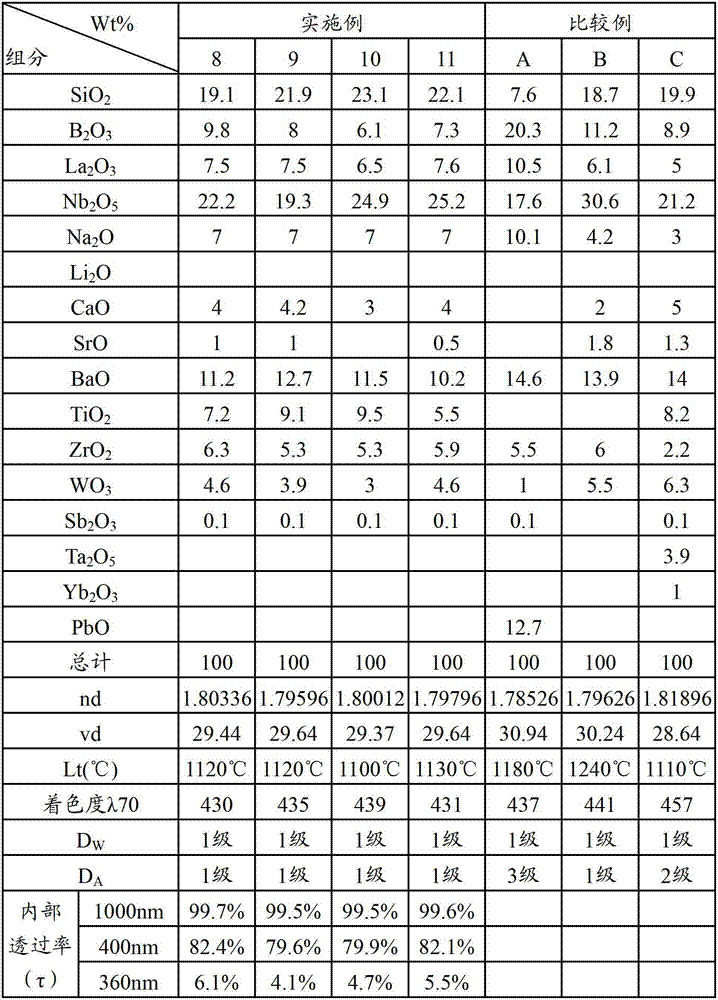

[0034] Tables 1 to 11 are typical experiments for obtaining heavy lanthanum flint optical glass with a refractive index (nd) between 1.78 and 1.82 and an Abbe number (vd) between 27 and 32 according to the present invention.

[0035]

[0036]

[0037] Note: 1. Lt in the table is the liquidus temperature, that is, the upper limit temperature of crystallization. The test is carried out by DTA (differential thermal analysis) method, and the temperature corresponding to the heat absorption peak with the highest temperature in the curve is Lt;

[0038] 2. The meaning of "coloring degree λ70" in the table is the corresponding wavelength when the spectral transmittance of glass is 70% (the thickness of the sample is 10mm);

[0039] 3. The chemical stability data in the table (D A 、D W ) is the result of testing according to the GB / T17129 standard using the powder method;

[0040] 4. The meaning of "internal transmittance τ-1000nm" in the table is the transmittance value at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com