Technological method for purifying1,4-butanediol and co-producing gamma-butyrolactone

A technology of butanediol and butyrolactone, which is applied in the field of 1,4-butanediol purification and co-production of γ-butyrolactone, can solve the problems of complex reactor structure and increasing difficulty, and achieve high selectivity, The effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

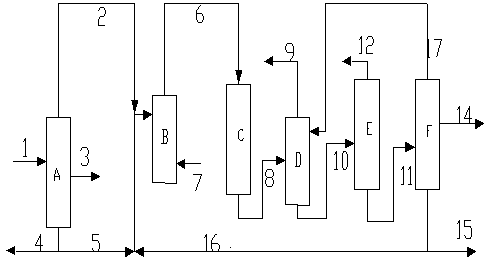

Image

Examples

Embodiment 1

[0032] The composition of crude 1,4-butanediol was: 0.36% of 2-(4-hydroxybutoxy)tetrahydrofuran, 0.75% of γ-butyrolactone, and 98.89% of 1,4-butanediol. The crude 1,4-butanediol stream enters the rectification tower A through pipeline 1. The rectification tower adopts a conventional packed tower and is operated under reduced pressure. Under this condition, the stream entering rectification tower A is separated, and the side line obtains 1,4-butanediol with a purity of 99.83% and enters the product tank area through pipeline 3. The overhead stream consists of: 2-(4-hydroxybutoxy ) tetrahydrofuran content 0.56%, γ-butyrolactone content 0.99%, 4-hydroxybutyric acid-4'-hydroxybutyl ester content 0.12%, 1,4-butanediol content 98.33%. Bottom stream composition: 2-(4-hydroxybutoxy)tetrahydrofuran content 0.02%, γ-butyrolactone content 0.01%, 4-hydroxybutyric acid-4'-hydroxybutyl ester content 0.24%, 1,4-butyric acid Glycol content 99.73%; part of the tower bottom stream is returned ...

Embodiment 2

[0034] The crude 1,4-butanediol stream containing 0.5% 2-(4-hydroxybutoxy)tetrahydrofuran enters the rectification tower A through pipeline 1, and the rectification tower adopts a conventional packed tower, operated under reduced pressure, and controlling the top pressure 3.0kPa, reflux ratio 15.0, the stream entering rectifying tower A is separated, and the 1,4-butanediol with a purity of 99.83% is obtained from the side line and enters the product tank area through line 3, and the bottom flow is all through line 5 and from line 2 The 1,4-butanediol stream containing 0.94% 2-(4-hydroxybutoxy)tetrahydrofuran at the top of the tower is mixed and then enters the vaporizer B. In the vaporization chamber B, it is contacted with the hot hydrogen coming from the pipeline 7 and is completely vaporized. , control the hydrogen / butanediol molar ratio of 3.5, enter the dehydrogenation reactor C through the pipeline 6, and carry out the dehydrogenation reaction under the conditions of cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap