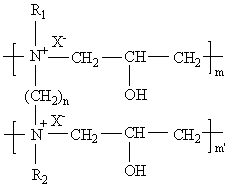

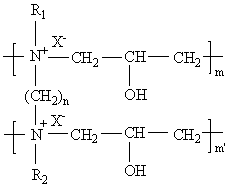

Cationic polyamine polymer, and preparation method and application thereof

A cationic polyamine and cationic technology, applied in the field of cationic polyamine polymers and their preparation, can solve the problems of difficult regulation of system rheology, unfavorable environmental protection, unfavorable environmental protection, etc. Water-soluble, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

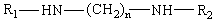

Method used

Image

Examples

Embodiment 1

[0020] In a 1000 mL four-necked round bottom flask, 60 g of ethylenediamine was added. The temperature was raised to 70°C under stirring. Gradually add 116 g of propylene oxide dropwise, control the reaction temperature to 60-100°C, and react for 1 h to obtain compound (II). Continue to heat up to 95°C, add 185g epichlorohydrin dropwise, and control the reaction temperature at 90-150°C. When the reaction system is thickened, add hydrochloric acid after maintaining for at least half an hour, the molar ratio of hydrochloric acid to ethylenediamine is 2:1, and react for 4 hours to obtain a yellow polyamine solution sample.

Embodiment 2

[0022] In a 1000 mL four-necked round bottom flask, 74 g of 1,3-propanediamine was added. The temperature was raised to 70°C under stirring. Gradually add 116 g of propylene oxide dropwise, control the reaction temperature to 60-100°C, and react for 2 hours to obtain compound (II). Continue to heat up to 95°C, add 185g epichlorohydrin dropwise, and control the reaction temperature within the range of 90-150°C. When thickening of the reaction system occurs, add hydrochloric acid after maintaining for at least half an hour. The molar ratio of hydrochloric acid to compound (II) is 1:2, and react for 3 hours to obtain a yellow polyamine solution.

Embodiment 3

[0024] In a 1000 mL four-necked round bottom flask, 88 g of 1,4-butanediamine was added. The temperature was raised to 70°C under stirring. Gradually add 116 g of propylene oxide dropwise, control the reaction temperature to 60-100°C, and react for 3 hours to obtain compound (II). Continue to heat up to 95°C, add 185g epichlorohydrin dropwise, and control the reaction temperature within the range of 90-150°C. When thickening occurs in the reaction system, add citric acid after maintaining for at least half an hour. The molar ratio of citric acid to compound (II) is 1:2, and react for 2 hours to obtain a yellow polyamine solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com