Thermosetting epoxy resin under microwave condition and degradation method of composite material of thermosetting epoxy resin in ionic liquid

A technology of ionic liquid and epoxy resin, which is applied in the field of microwave irradiation technology and the recycling of waste resin materials, can solve the problems of waste of recyclable resources, land pollution, secondary pollution, etc., to reduce the degradation reaction time and improve environmental protection The effect of performance and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The essence of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the content of the present invention is not limited thereto.

[0017] The process and steps of the embodiment are as follows:

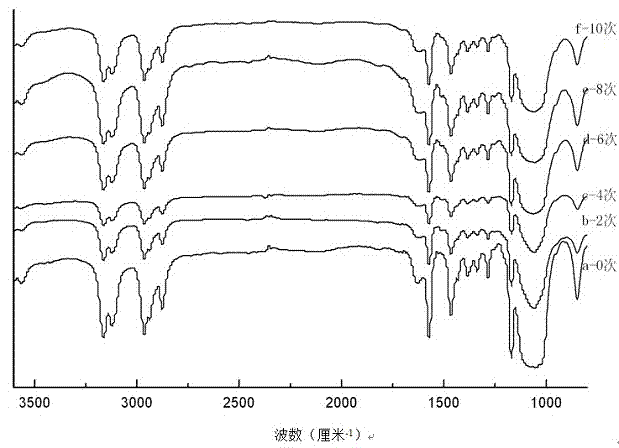

[0018] First, crush the thermosetting epoxy resin or its composite material into flakes or granules of a certain size, clean them, put them in an oven to dry at 60°C, and mix 2g of thermosetting epoxy resin granules and 10g of ionic liquid BmimBF 4 Mix and place in a flask, and make the epoxy resin powder completely submerged in the ionic liquid; turn on the microwave device and react for 20 minutes, take out the flask and place it in a ventilated place to cool rapidly; then dissolve the degraded mixture with methanol, and collect the washing liquid, Finally, the methanol solution of the liquid phase product is obtained; the methanol solution of the liquid phase product is subjected to vacuum distillation, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com