Quickly dispersed asphalt powder for drilling fluid and preparation method of quickly dispersed asphalt powder

A kind of asphalt powder and asphalt technology, which is applied in the anti-slump agent of rapid dispersion (quick release) asphalt powder for drilling fluid and its preparation field, which can solve the problems of poor product stability, insufficient modification, limited transportation, etc., and achieve Low requirements for equipment and environmental conditions, good water dispersion stability, and excellent plugging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

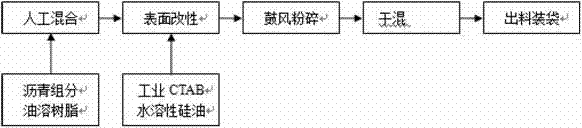

Method used

Image

Examples

Embodiment 1

[0085] (1) Weigh 100kg of natural asphalt 1#, 50kg of polymer modified oxidized asphalt (PMA) and 50kg of oil-soluble resin (PRC9), and place them on the ground for preliminary mixing; during the stirring process, spray 6kg of industrial grade ten on the surface of the material Hexaalkyltrimethylammonium bromide (CTAB) and 12kg water-soluble silicone oil (OSO-w) for preliminary surface modification;

[0086] (2) Transfer the material obtained in step (1) to a blast mill for crushing;

example 1

[0089] Table 1 Example 1 quality inspection results

[0090]

[0091]

Embodiment 2

[0093] (1) Weigh 100kg of natural asphalt 2#, 100kg of polymer modified oxidized asphalt (PMA) and 50kg of oil-soluble resin (PRC9), and place them in an open mixing tank for preliminary mixing; during the stirring process, spray 6kg on the surface of the material Nonionic surfactant Span80 and 8kg nonionic surfactant Tween80 for preliminary surface modification;

[0094] (2) Transfer the material obtained in step (1) to a blast mill for crushing;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com