Gas extraction method by using major diameter pipeline and sealing transverses between mine goaf and tail roadway

A large-diameter pipe and goaf technology is applied in the field of gas extraction in coal mines, and can solve the problems of ineffective interference with the seepage field in the goaf, small drainage flow, and frequent gas overruns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

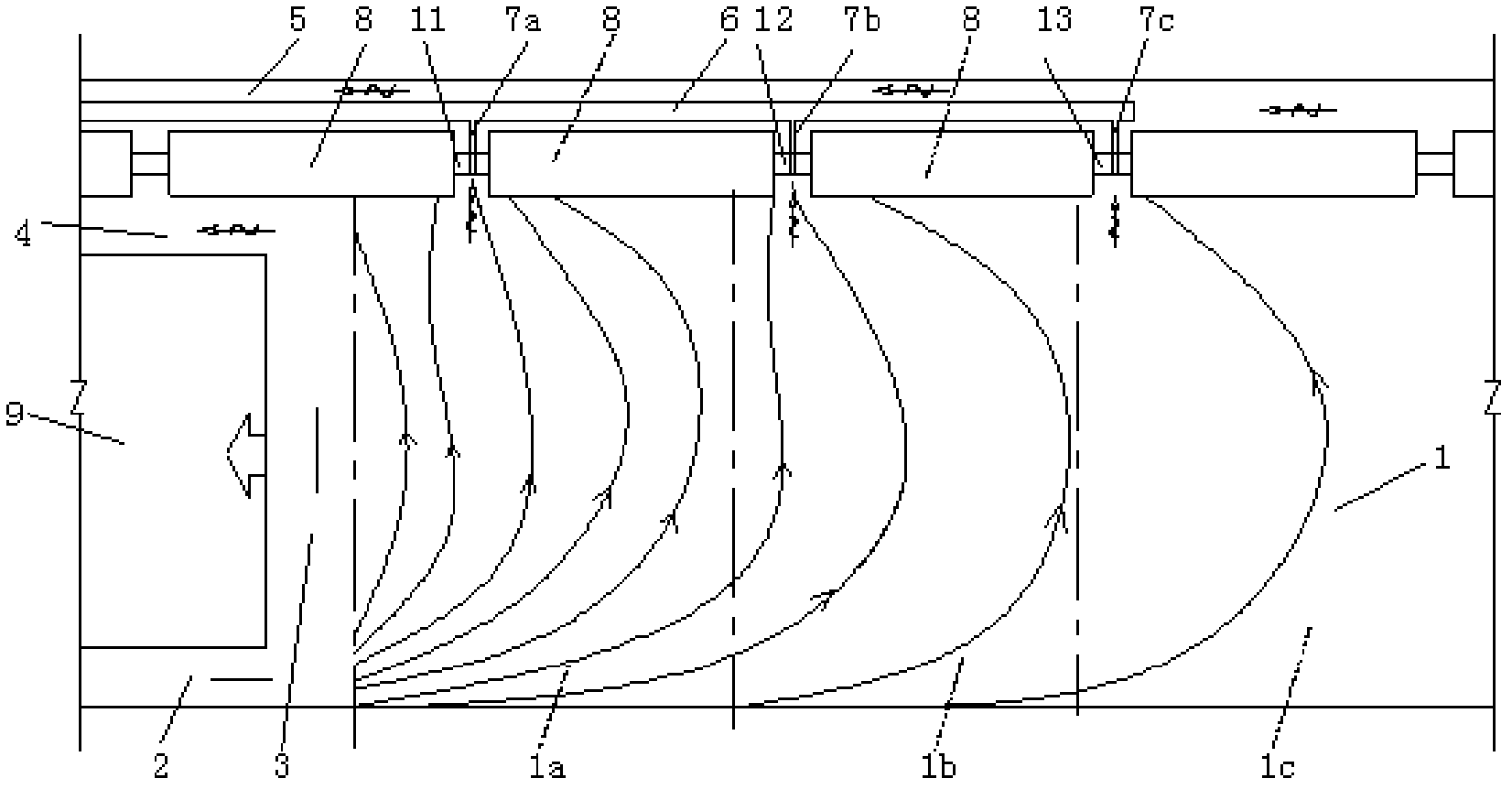

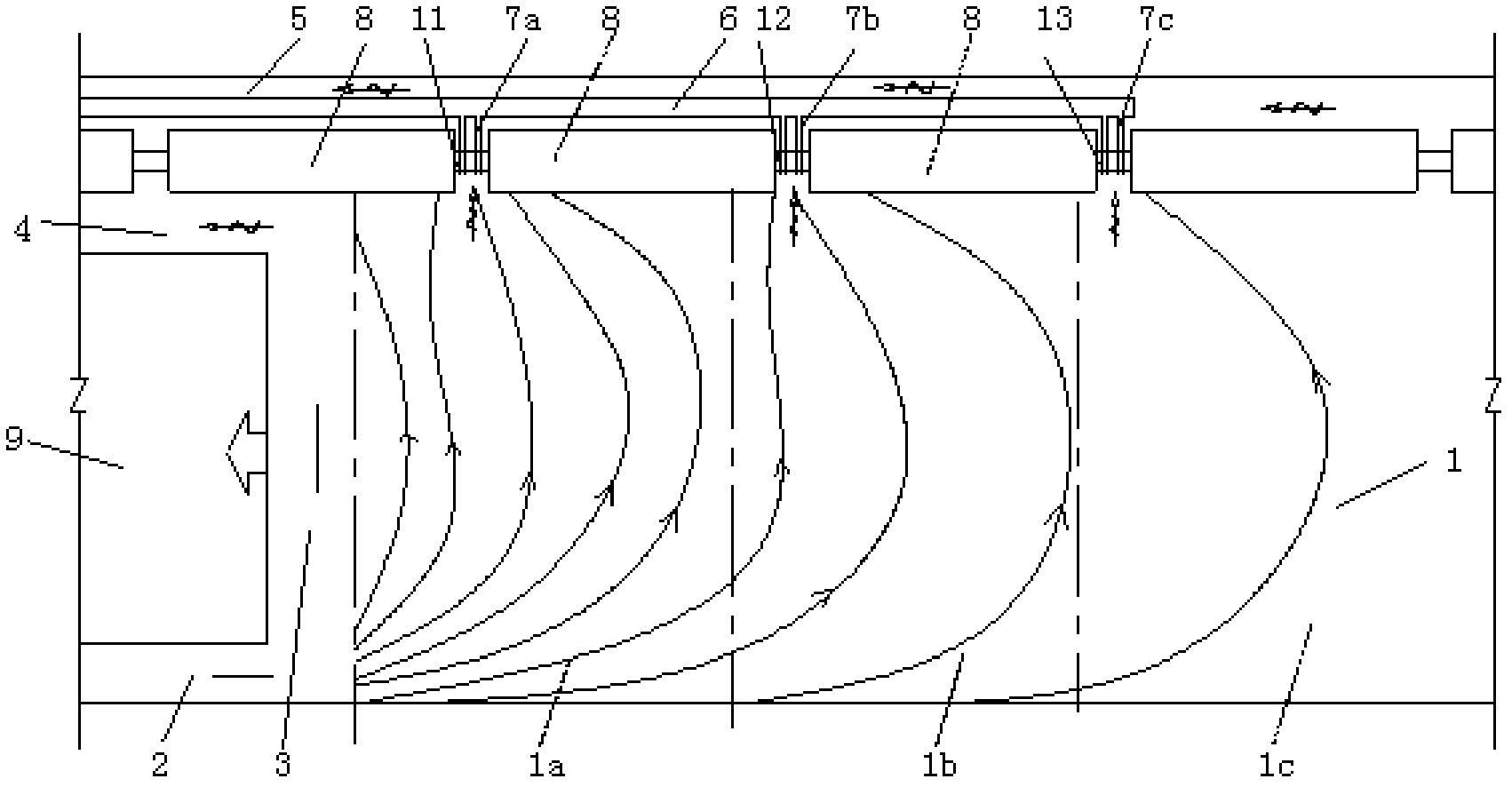

[0019] Such as figure 1 As shown in the structure schematic diagram of the method for the closed gas drainage of the large-diameter pipeline in the tailgate transversely connected to the goaf of the present invention, the method for the closed gas drainage of the large-diameter pipeline in the tailgate transversely connected to the goaf of the present invention includes the following steps step:

[0020] Divide goaf 1 into main extraction sub-area, sub-extraction sub-area and sub-extraction sub-area 1a, 1b, 1c from close to fully mechanized mining face 3 to away from fully mechanized mining face 3;

[0021] Establish a U-shaped gas channel from the air inlet lane 2 to the air return lane 4 via the fully mechanized mining face 3;

[0022] Lay the gas extraction pipeline 6 in the gas tailway 5;

[0023] The closed gas tailgate 5 and the three goaf sub-areas traverse 11, 12, and 13, so that the gas tailgate 5 is isolated from the goaf;

[0024] The branch pipe systems 7a, 7b, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com