Efficient low-load wing section special for horizontal shaft wind turbine blade and designing method of wind section

A technology of wind turbine blade and design method, which can be applied to wind turbines, wind turbines, mechanical equipment and other directions that are consistent with the wind direction, and can solve problems such as increasing the ultimate load of the blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

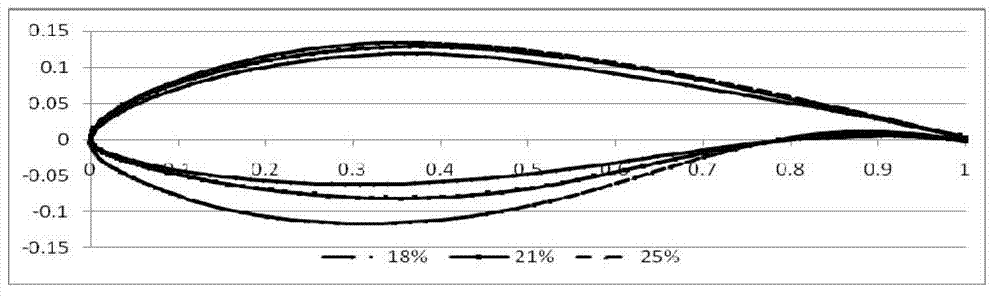

[0043] The present invention will be described in detail below in conjunction with examples and accompanying drawings.

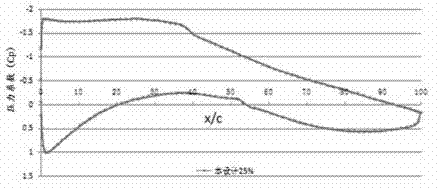

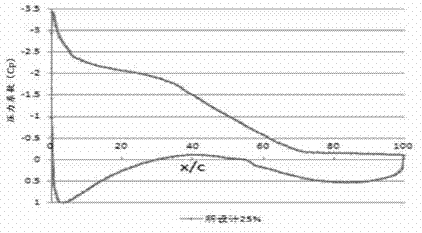

[0044] The force on the airfoil is the resultant force of the distributed forces acting on the upper and lower surfaces. There are two types of surface forces, one is normal force and the other is tangential force. Define the resultant force perpendicular to the incoming flow in the far front as the lift force, and the resultant force in line with the direction of the incoming flow in the far side as the drag force. Lift and drag are usually expressed as dimensionless lift and drag coefficients. The lift coefficient and drag coefficient of the airfoil change with the angle of attack, which can form the lift characteristic and drag characteristic curve. At first, the lift coefficient of the airfoil increases with the angle of attack. When the angle of attack reaches a certain value, the lift coefficient reaches its maximum value, which is recorded as the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com