Flow dividing and collecting valve bank, hydraulic system, load sensitive type hydraulic system and engineering machine

It is a technology of dividing and merging and valve group, which is applied to mechanical equipment, fluid pressure actuating devices, servo motor components, etc. It can solve the problem of inability to adapt to the control of load-sensitive hydraulic pumps, complex structure of dividing and merging valves, and unreliable work. problem, to achieve the effect of good automatic adjustment performance and energy saving characteristics, excellent working performance and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

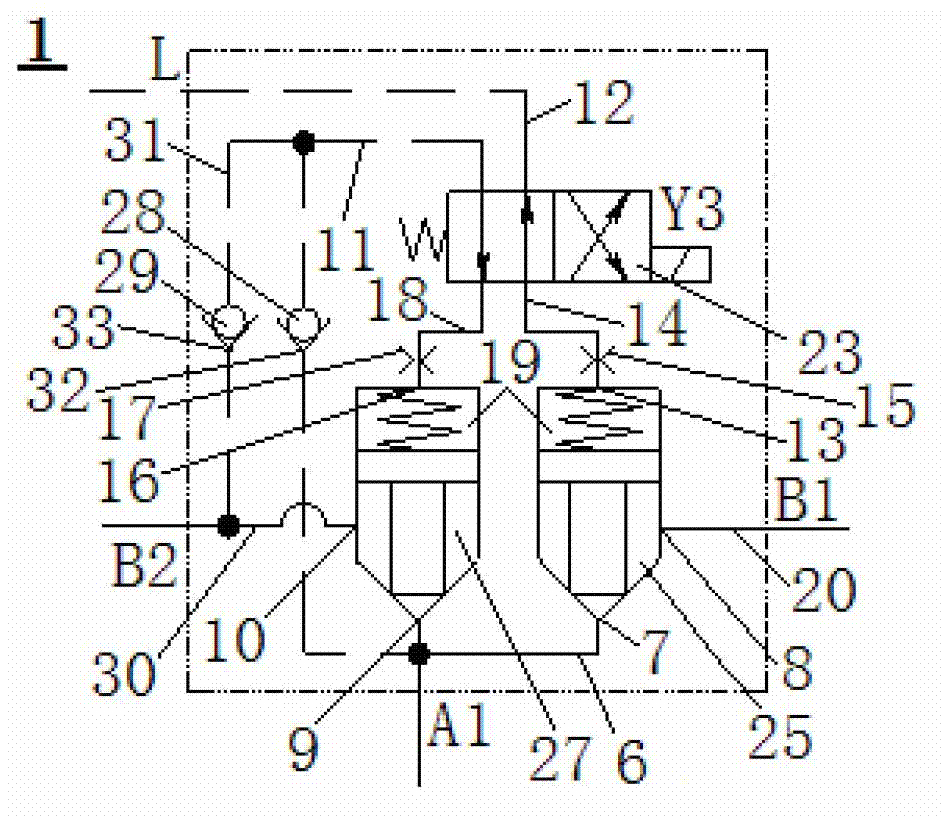

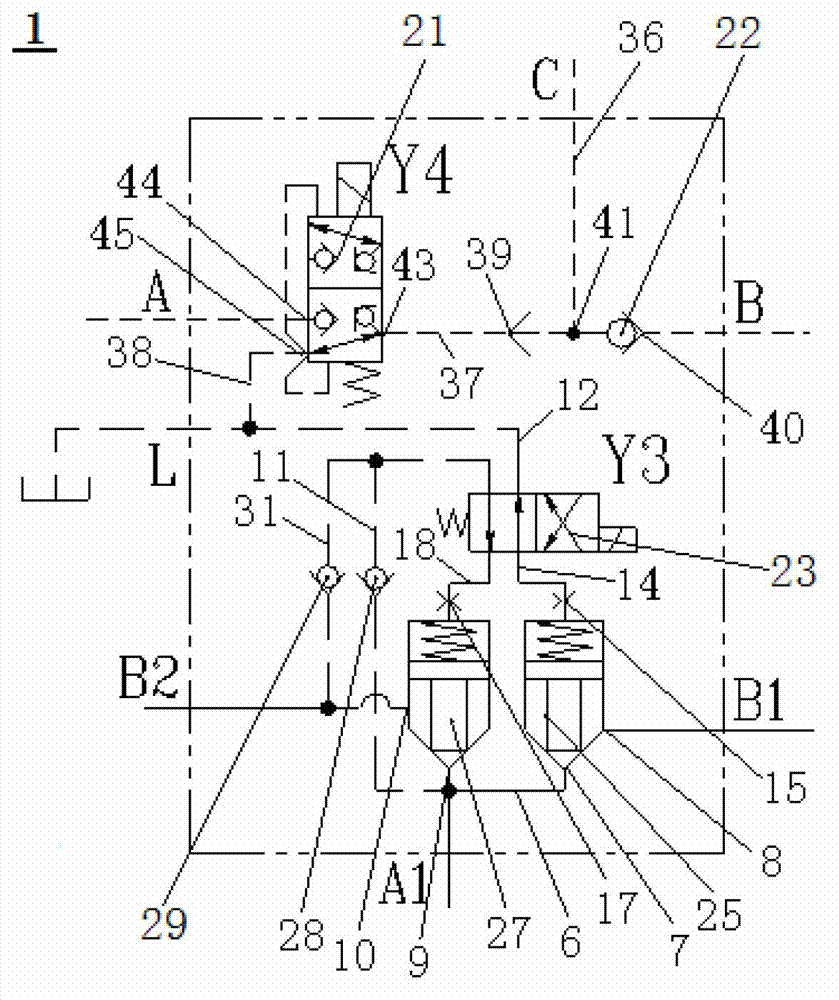

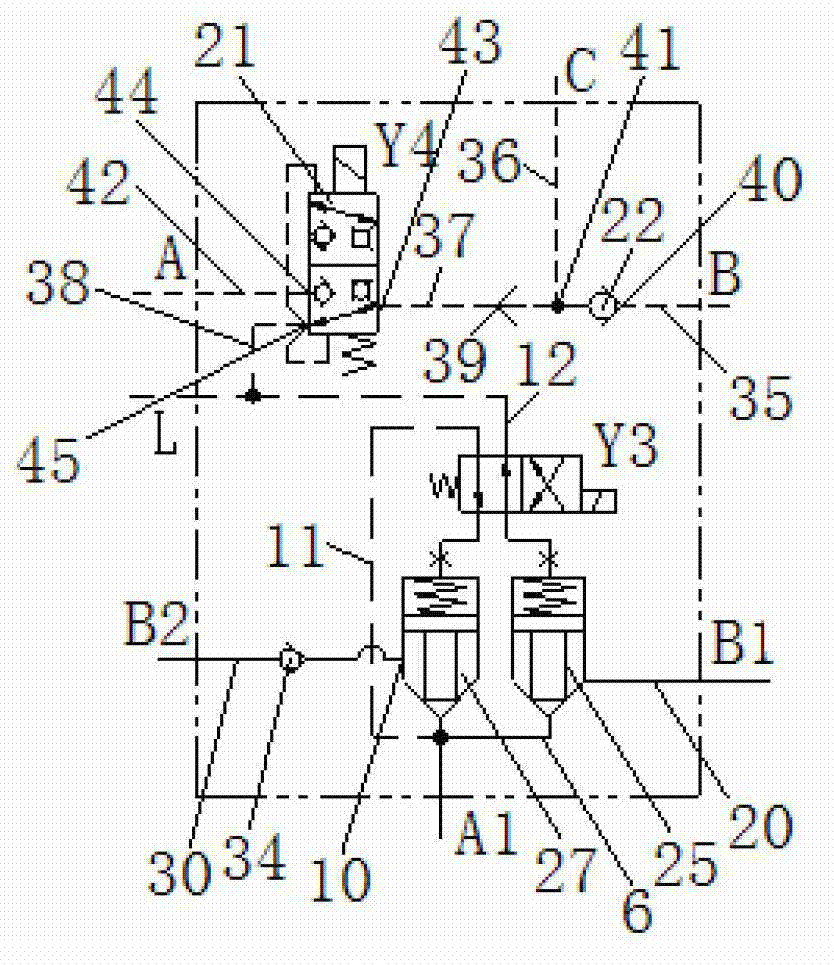

[0059] For those skilled in the hydraulic field, the technical conception of a hydraulic device lies more in its hydraulic connection relationship, and there may be various specific mechanical realization structures. E.g, Figure 1 to Figure 3 The branch and confluence valve group 1 of the specific implementation form shown can be formed as an integral composite valve. In this case, Figure 1 to Figure 3 The corresponding A1, B1, B2, A, B, C and L etc. in can be the corresponding oil ports on the valve body of the integral composite valve, but obviously, Figure 1 to Figure 3 The sub-combination valve gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com