Metering tube piston head structure for high-accuracy analysis meter

A metering tube and analyzer technology, applied in the research field of physical or chemical properties, can solve the problems affecting the measurement accuracy, out of step, control motor blocking step, etc., and achieve the effect of reducing the cost of use, reasonable structure, and low leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation will be described in detail below in conjunction with the accompanying drawings:

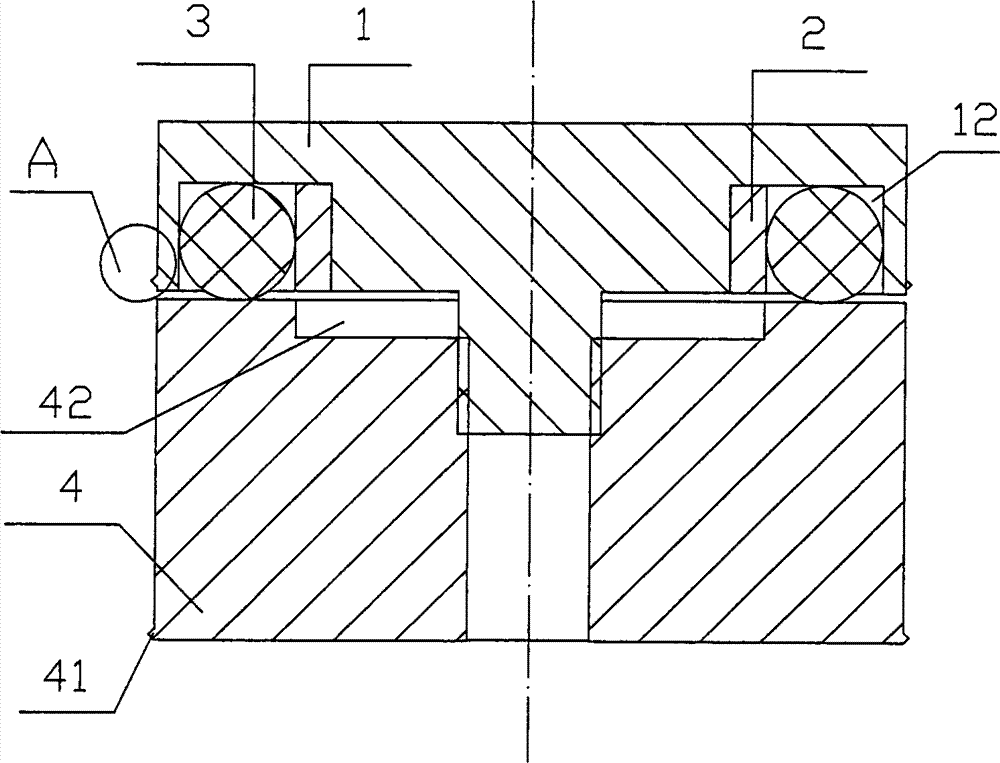

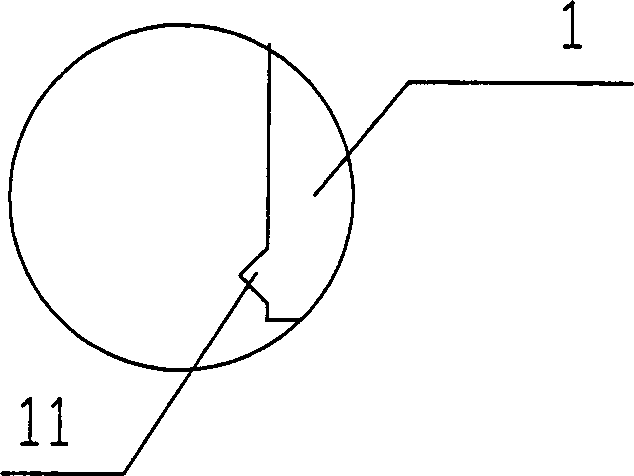

[0011] exist Figure 1 ~ Figure 2 In the illustrated embodiment of the present invention, a metering tube piston head structure for an analyzer includes: a piston top cover 1, a hard inner lining 2, an elastic sealing ring 3, and a body 4; The end face is provided with an annular groove 12, the shaft center of the piston top cover is provided with a short shaft with a male thread, the hard lining 2 is in the form of a ring, the body 4 is a cylinder, and the upper end of the cylinder is provided with a concave 41, the cylinder The shaft center is provided with a screw hole for fixing the short axis of the piston top cover 1; the inner side wall of the hard lining 2 is fastened to the inner side wall 12 of the annular groove of the piston top cover 1, and the elastic sealing ring 3 is installed in the hard inner wall. In the space formed by the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com