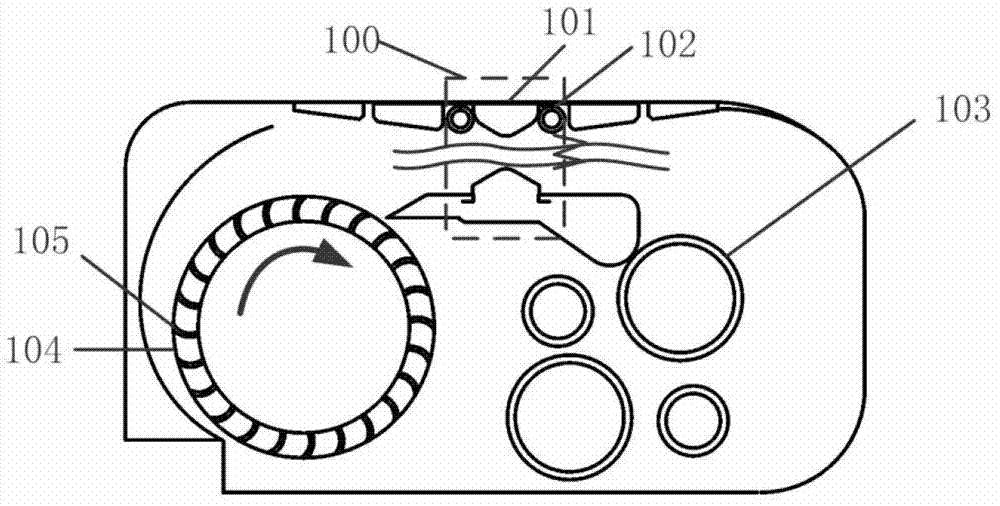

Device and method for measuring disturbance of cross flow fan impeller of pulsed gas laser

A technology of a cross-flow fan and a measuring device, which is applied in the field of optical measurement, can solve problems such as inability to obtain, and achieve the effects of convenient operation, strong practicability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

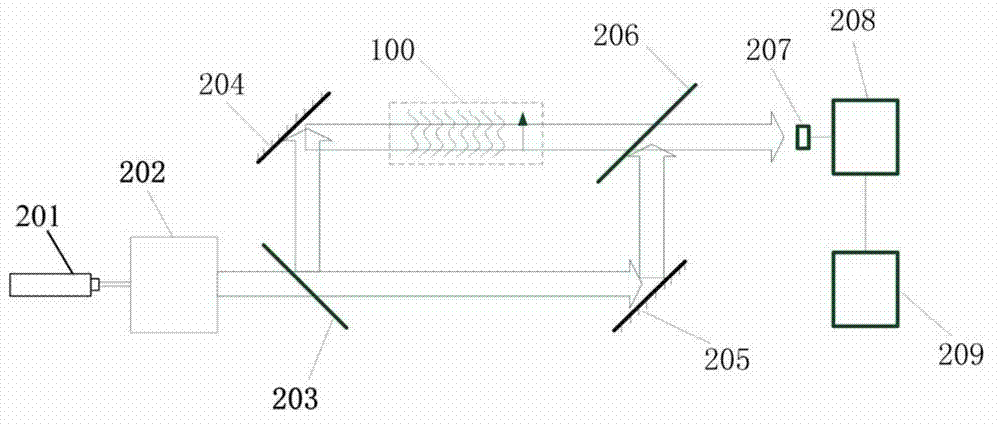

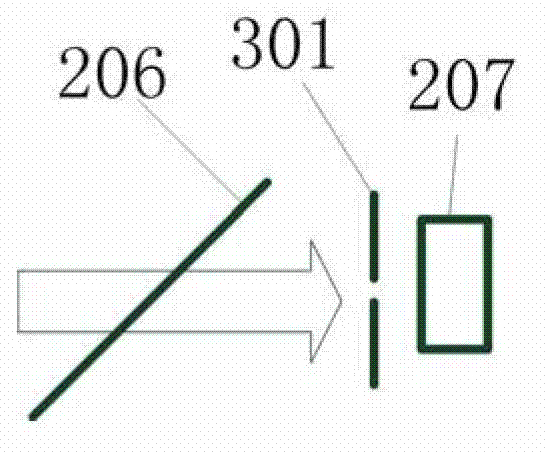

[0019] Before the fan works, the Mach-Zehnder interference device is adjusted to infinitely thick interference fringes, that is, the optical path difference between the two beams of the Mach-Zehnder interference system is an integer multiple of the wavelength. According to the principle of double-beam interference, the light intensity I at this time is :

[0020] I=4I 0 cos 2 (kΔ) = 4I 0 (1)

[0021] Where k is the wave vector, Δ is the optical path difference between the two beams, I 0 is the light intensity of each beam. It can be seen from the above formula that the light intensity before the fan works is a fixed value. When the fan is working, the optical path difference Δ of the two beams in the Mach-Zehnder interference system will change, and the change of the optical path difference Δ is mainly caused by the change in the refractive index of the gas caused by the fan working, so the fan blades are staggered The disturbance of will make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com