Atomic Current Sensor

A technology of current sensor and sensor signal, applied in the field of sensors, can solve the problem that electromagnetic sensors cannot meet the requirements well, and achieve the effects of simple structure, long working life and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

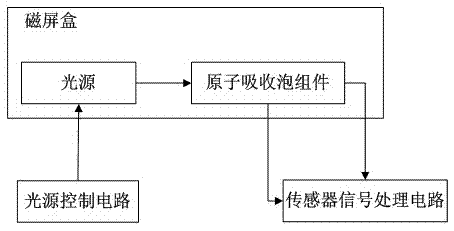

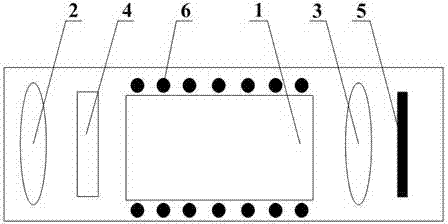

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the atomic current sensor of the present invention completes the signal transmission function by filtering light.

[0043] Such as figure 1 As shown, the electronic current sensor includes a light source control circuit, a light source, an atomic absorption bubble assembly and a sensor processing circuit.

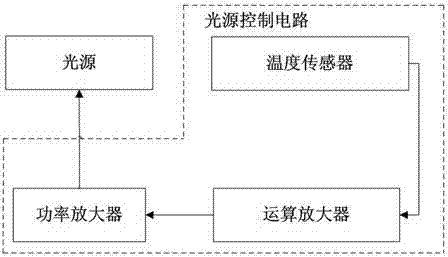

[0044] Such as figure 2 As shown, the light source control circuit is mainly used to sense and amplify voltage, and finally output high-power current. Wherein the temperature sensor on the light source control circuit in this embodiment is preferably a thermistor, and the resistivity of the temperature sensor changes with the change of temperature, so according to the change of the resistivity, the magnitude of the voltage loaded on it is constantly changing, and the voltage is passed through the operational amplifier. After amplification, the current is continuously amplified through the power ampl...

Embodiment 2

[0057] The difference from Embodiment 1 is that in order to better realize the present invention, this embodiment additionally sets a laser cover on the laser tube to keep the temperature of the laser tube constant. Since the laser tube itself will generate heat, the light source control circuit The thermistor is set in the laser cover, and the heating temperature of the power amplifier is controlled by feedback according to the temperature in the laser cover, which can better ensure that the frequency of the laser emitted by the laser tube remains constant and improve the filtering accuracy.

Embodiment 3

[0059] The difference from Example 1 is that, as Figure 5 As shown, the sensor signal processing circuit includes a band-pass amplifier and a 90° phase shifter. The band-pass amplifier is connected with the photocell in the atomic absorption bubble assembly, and the output signal of the photocell is shifted by 90°. The 90° phase shifter has There are two output terminals: one of the output terminals outputs a signal to the coupling coil for signal feedback, and controls the coupling coil to generate a magnetic field; the output signal of the other output terminal is the signal output by the atomic current sensor. At this point, the present invention has completed its function.

[0060] Among them, the signal processing method performed by the sensor signal processing circuit is called active type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com