Current sensor of CAN (controller area network) bus interface for mine

A CAN bus and current sensor technology, applied in the field of mine CAN bus interface current sensor, can solve the problems of insufficient interface, unable to collect information, limited analog interface, etc., to achieve simple interface, save bus conflict arbitration time, strong correction The effect of wrong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

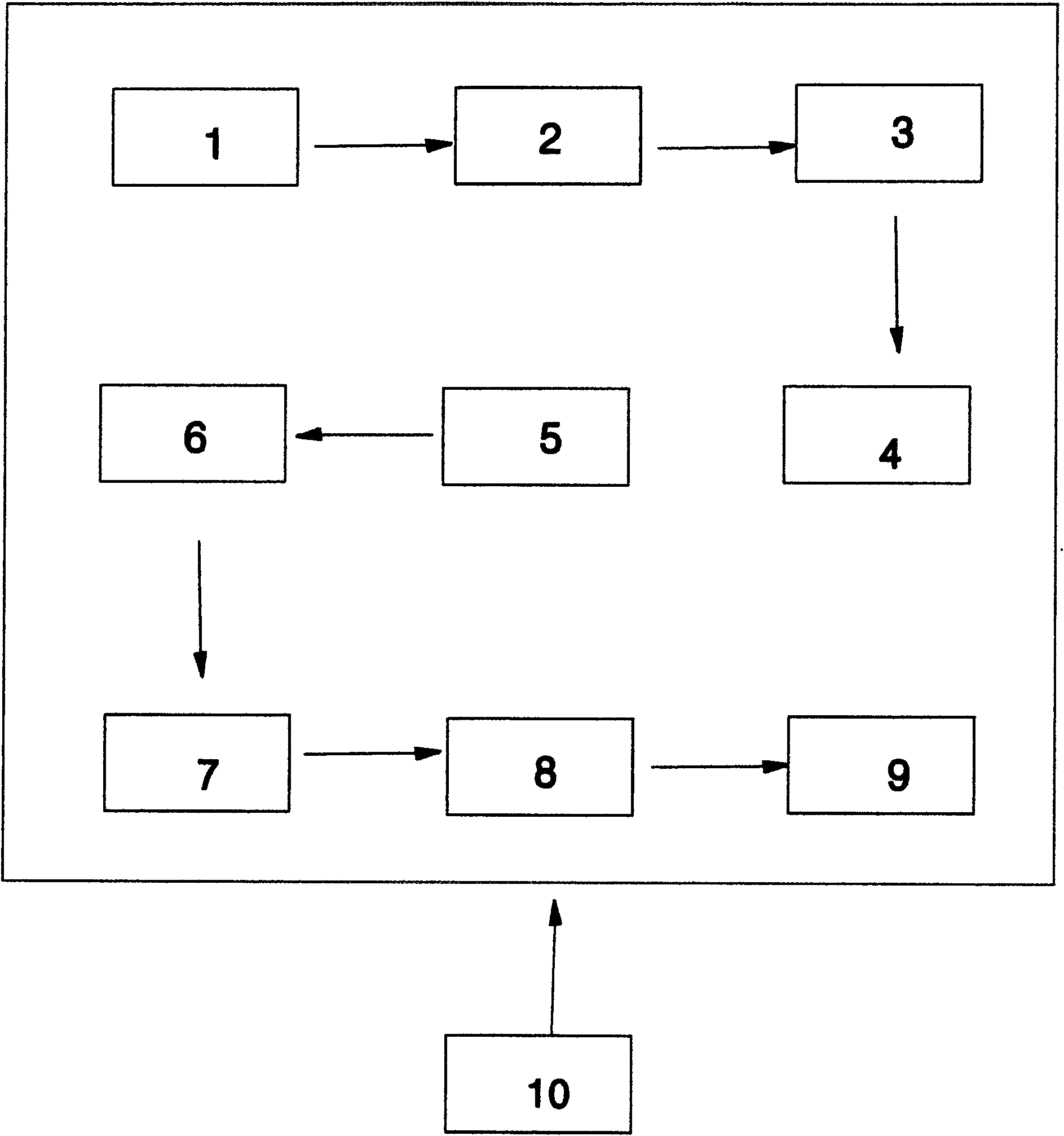

[0014] The present invention consists of an electromagnetic induction magnetic ring 1, a rectifier circuit 2, a collector 3, a signal amplifier 4, a filter 5, an A / D converter 6, a data microprocessor 7, a CANBUS interface 8, a CAN drive transceiver 9 and a DC power supply 10 components, firstly, the input current is converted into a weak AC current signal that is convenient to process through the electromagnetic induction magnetic ring 1 through the principle of mutual induction or Hall principle, and then rectified by the rectifier circuit 2, and part of the signal is collected by the collector 3 and sent to the signal amplifier 4 for further processing. It is amplified, then filtered by the filter 5, and then converted into a digital signal by a high-precision A / D converter 6, and then the data is processed by software filtering and linearization software, through strong anti-interference ability and CANBUS interface The data microprocessor 7 of 8 converts the data into CANB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com