High-power factor light-emitting diode driving circuit structure

A high power factor, light-emitting diode technology, applied in the direction of lamp circuit layout, light source, electric light source, etc., can solve the problems of increasing the standby power consumption of the driving circuit, limiting the miniaturization of the whole machine, and unfavorable control circuit area, etc., to achieve the function Rich, reduced standby power consumption, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the technical content of the present invention more clearly, the following embodiments are given for detailed description.

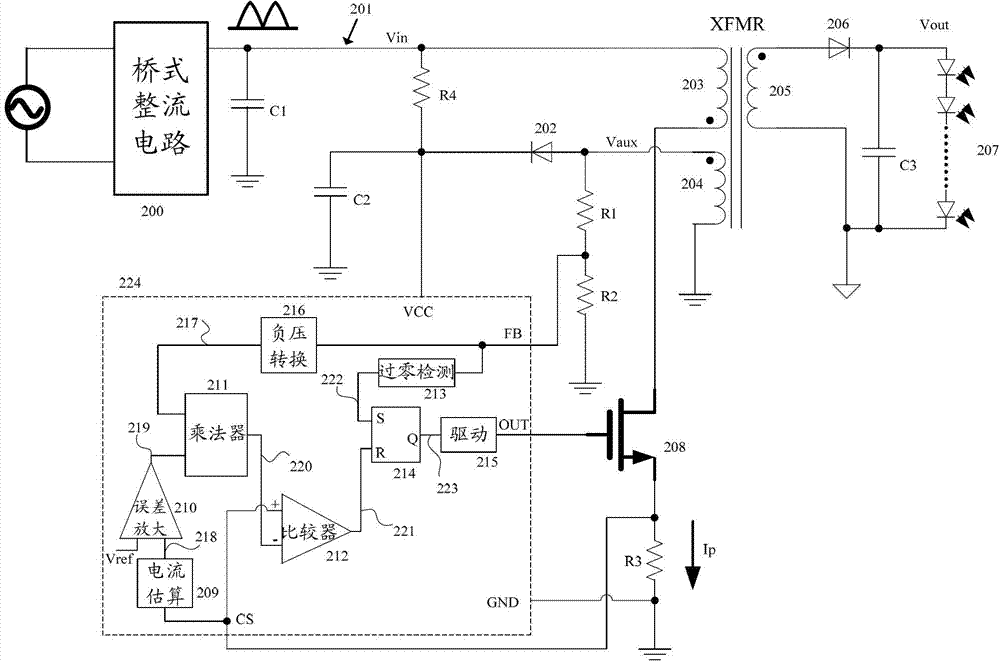

[0032] see figure 2 As shown, it is a schematic structural diagram of the high power factor light emitting diode driving circuit of the present invention.

[0033] In an embodiment, the high power factor LED driving circuit structure includes a bridge rectifier circuit 200 and a transformer XFMR, the transformer XFMR includes a primary winding 203, a secondary winding 205 and an auxiliary winding 204, the bridge rectifier circuit The input end of 200 is connected to the AC voltage source, the output end is connected to the primary winding 203 through the bus bar 201 , and the secondary winding 205 is connected to the light-emitting diode load 207 . The circuit structure also includes a drive control circuit module, a loop voltage sampling circuit module and a power tube 208; the drive control circuit module includes a powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com