Food-grade linoleic acid micro-emulsion carrier and preparation method thereof

A linoleic acid, food-grade technology, applied in the field of microemulsion carrier and its preparation, can solve the problems such as the inability to obtain a uniform microemulsion system, and achieve the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

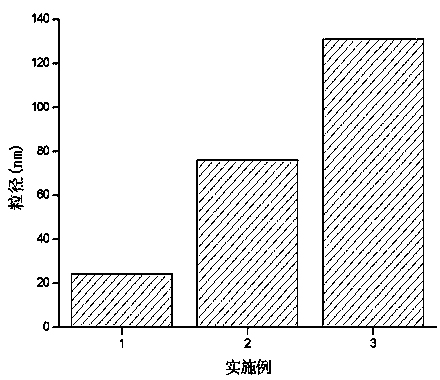

Embodiment 1

[0027] The components and weight percentages of the food-grade linoleic acid microemulsion carrier in this embodiment are: Tween20 ethanol mixture 18%, linoleic acid 2%, water 80%, and the mass ratio of Tween20 to ethanol is 4:1. The preparation method of the linoleic acid microemulsion carrier in this example is as follows: under the condition of continuous stirring, the stirring rate is 100 rpm, and the Tween20 ethanol mixture is added to the mixing kettle first, then linoleic acid is added, and finally water is added to obtain a clear A transparent and uniform system is the desired microemulsion system.

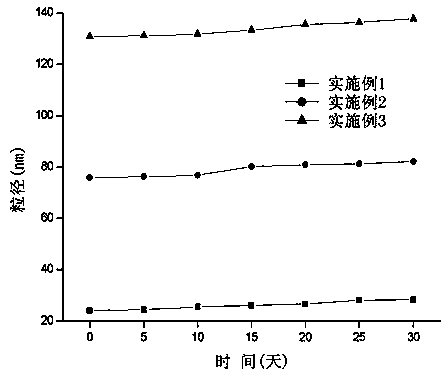

[0028] The stability of the particle size of the microemulsion carrier of this example was followed up. The microemulsion of this example was stored at room temperature and protected from light, and the particle size was measured every 3 days. The results of the change in particle diameter of the microemulsion of the example within 30 days are shown figure 2 . After 30 day...

Embodiment 2

[0030] The components and weight percentages of the food-grade linoleic acid microemulsion carrier in this embodiment are: Tween20 ethanol mixture 16%, linoleic acid 4%, water 80%, and the mass ratio of Tween20 to ethanol is 3:2. The preparation method of the linoleic acid microemulsion carrier in this example is as follows: under the condition of continuous stirring, the stirring rate is 100 rpm, and the Tween20 ethanol mixture is added to the mixing kettle first, then linoleic acid is added, and finally water is added to obtain a clear A transparent and uniform system is the desired microemulsion system.

[0031] The stability of the particle size of the microemulsion carrier of this example was followed up. The microemulsion of this example was stored at room temperature and protected from light, and the particle size was measured every 3 days. The results of the change in particle diameter of the microemulsion of the example within 30 days are shown figure 2 . After 30 day...

Embodiment 3

[0033] In this embodiment, the components and weight percentages of the food-grade linoleic acid microemulsion carrier are: Tween20 ethanol mixture 14%, linoleic acid 6%, water 80%, and the mass ratio of Tween20 to ethanol is 4:1. The preparation method of the linoleic acid microemulsion carrier in this example is as follows: under the condition of continuous stirring, the stirring rate is 100 rpm, and the Tween20 ethanol mixture is added to the mixing kettle first, then linoleic acid is added, and finally water is added to obtain a clear A transparent and uniform system is the desired microemulsion system.

[0034] The stability of the particle size of the microemulsion carrier of this example was followed up. The microemulsion of this example was stored at room temperature and protected from light, and the particle size was measured every 3 days. The results of the change in particle diameter of the microemulsion of the example within 30 days are shown figure 2 . After 30 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com