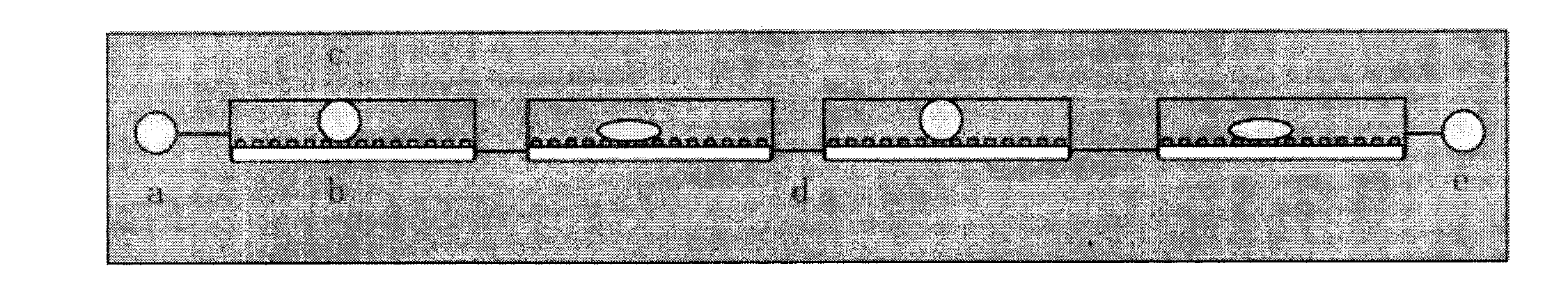

PH response micro pump based on micro-fluidic chip and preparation method thereof

A technology of microfluidic chips and micropumps, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., to achieve the effects of cost reduction, good application prospects, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The microstructure and microchannel pattern of the two-layer chip of the microfluidic chip with controllable microfluidic flow are designed and drawn by computer-aided design software. The microstructure and microchannel of the two-layer polymethyl methacrylate (PMMA) chip were processed and prepared by the numerical control CNC system. The chips of each layer were cleaned with tap water and distilled water respectively, and the remaining fingerprints, oil stains and other stains on the surface of the chip were wiped with ethanol. On the double-sided adhesive film, the required microstructures and microchannels were processed with a cutting machine. The two-layer chip is carefully aligned, glued, and pressure-sealed to form a smart micropump based on a microfluidic chip. The sample solution is added to the injection hole of the microfluidic chip, and the solution enters the microchannel driven by an external peristaltic pump. In the micropump area of the microchannel,...

Embodiment 2

[0024] The microstructure and microchannel graphics of the two-layer chip of the centrifugal microfluidic chip were designed and drawn by computer-aided design software. The microstructure and microchannel of the two-layer disc-shaped polycarbonate (PC) chip were processed and prepared by the numerical control CNC system. The chips of each layer were cleaned with tap water and distilled water respectively, and the remaining fingerprints, oil stains and other stains on the surface of the chip were wiped with ethanol. On the double-sided adhesive film, the required microstructures and microchannels were processed with a cutting machine. The two-layer chip is carefully aligned, glued, and pressure-sealed to form a smart micropump based on a microfluidic chip. The sample solution is added to the injection hole of the microfluidic chip, and the solution enters the microchannel driven by an external peristaltic pump. In the micropump area of the microchannel, the surface responds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com