Warm/hot medium hydro-forming device for sheets

A liquid-filled forming and warming technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of low forming temperature, narrow material adaptability, no cooling device, etc., to ensure uniformity and longevity. Time running, the effect of the best formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

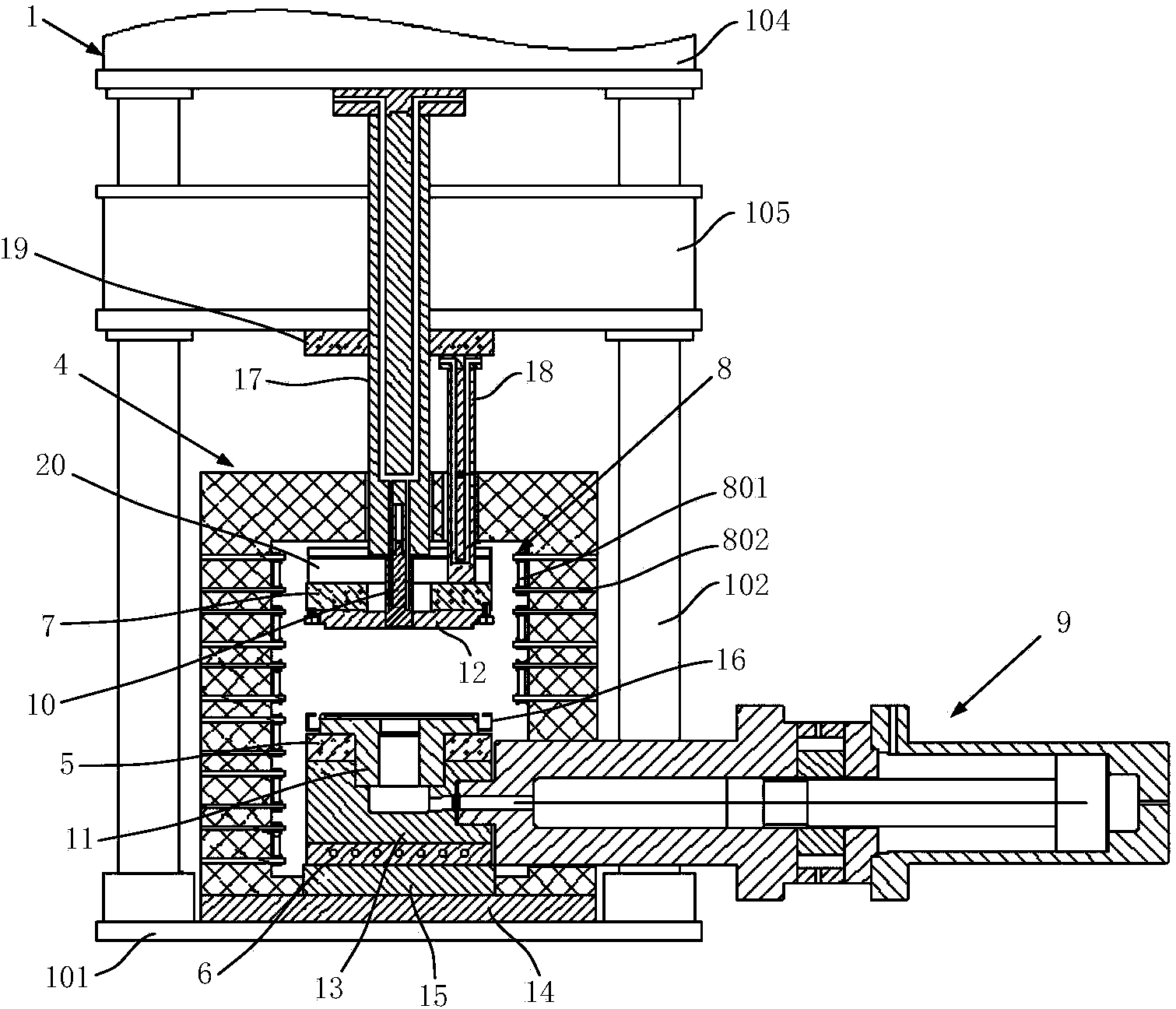

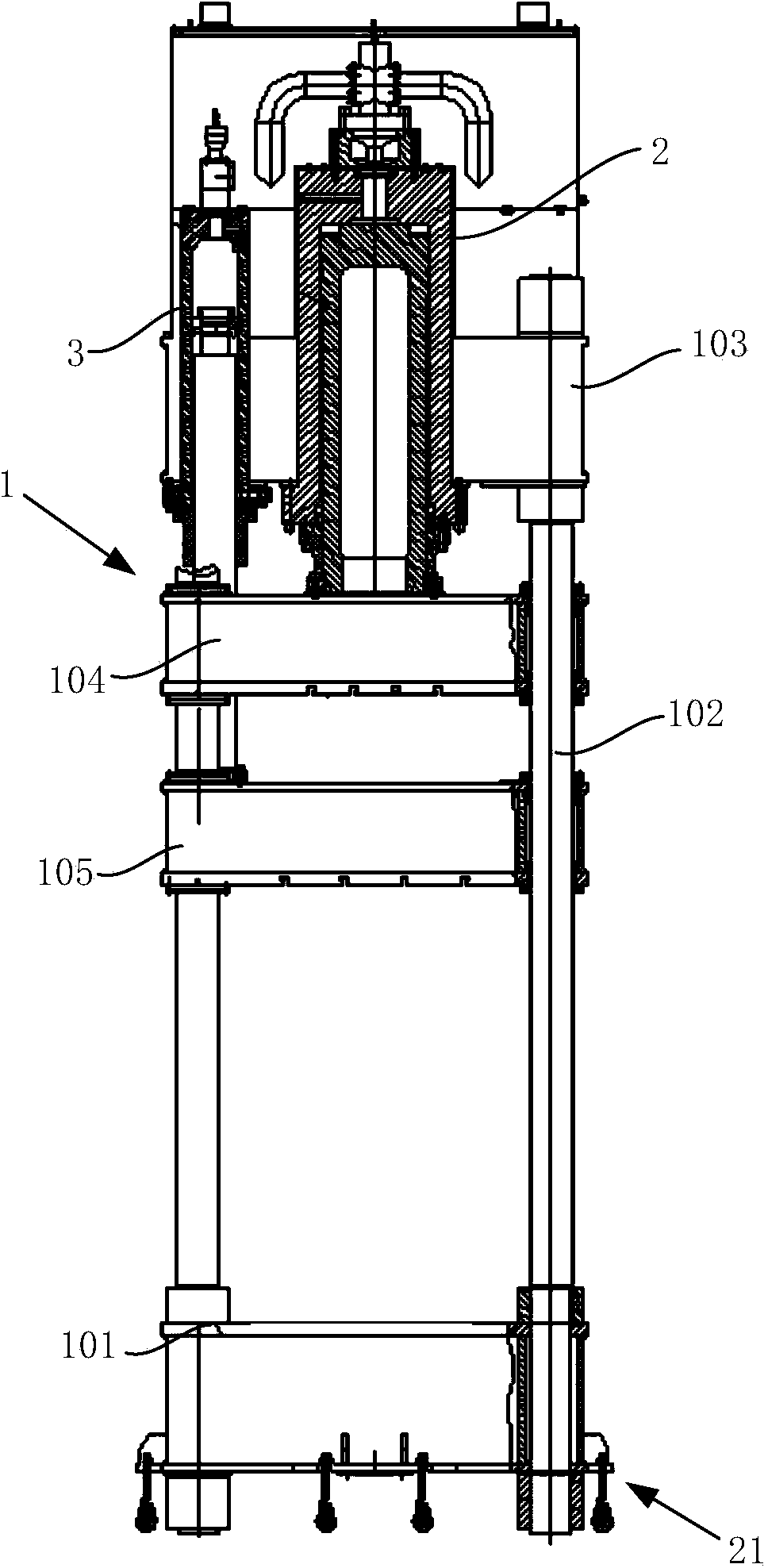

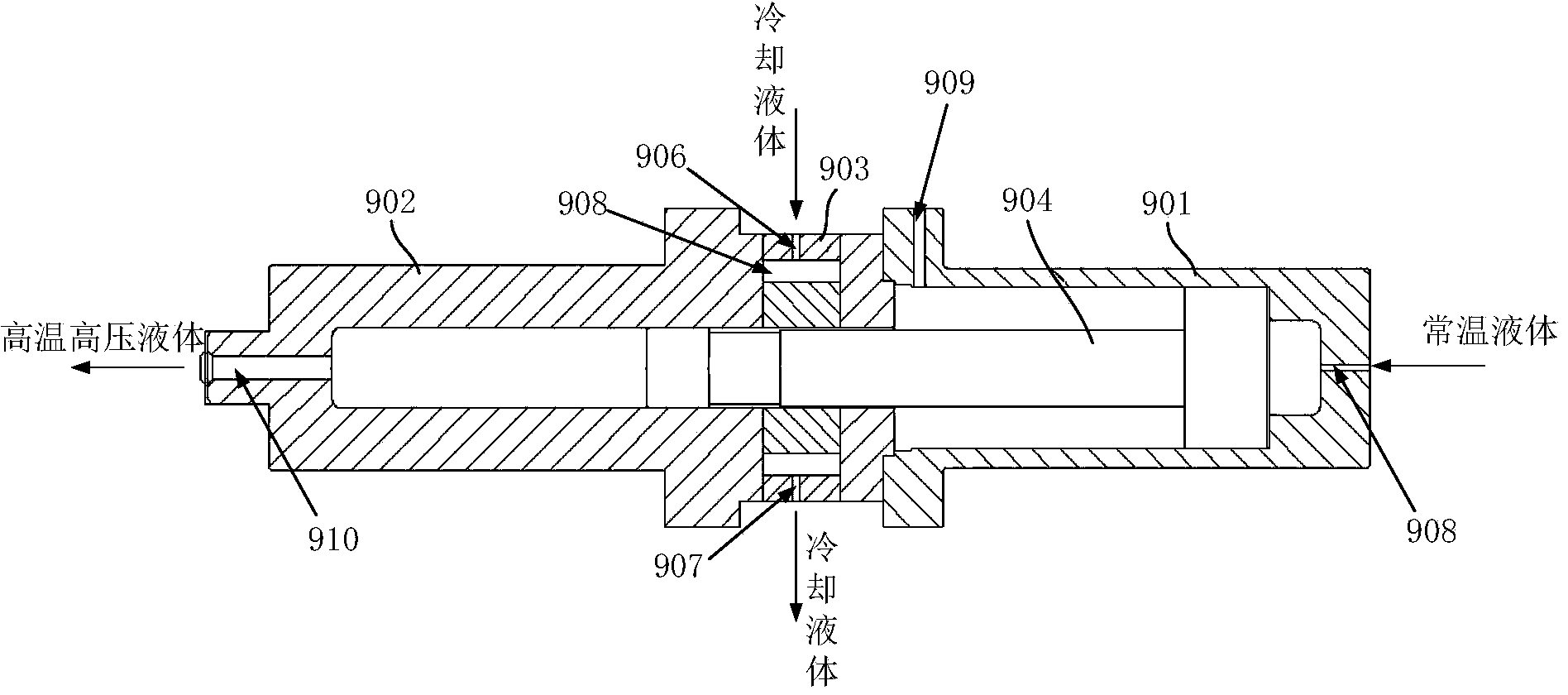

[0037] Warm and hot medium liquid-filled forming equipment for plates of the present invention, such as figure 1 , figure 2 As shown, it includes a universal double-acting hydraulic machine frame 1, a main cylinder 2, a blank holder cylinder 3, a furnace body 4, a heating plate A5, a heating plate B6, a heating plate C7, an electric heating component 8, a supercharger 9, a punch 10, Die 11, blank holder 12 and liquid-filled chamber 13.

[0038] Among them, the frame 1 is composed of a base 101, a column 102, an upper beam 103, a master cylinder beam 104, and a blanking beam 105; there are n columns 102, n≥2, and they are vertically fixed on the base plate 14. From top to bottom, the upper beam 103, the main cylinder beam 104 and the blanking beam 105 are horizontally socketed; the upper beam 103 is relatively fixed to the n columns 102, and the main cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com