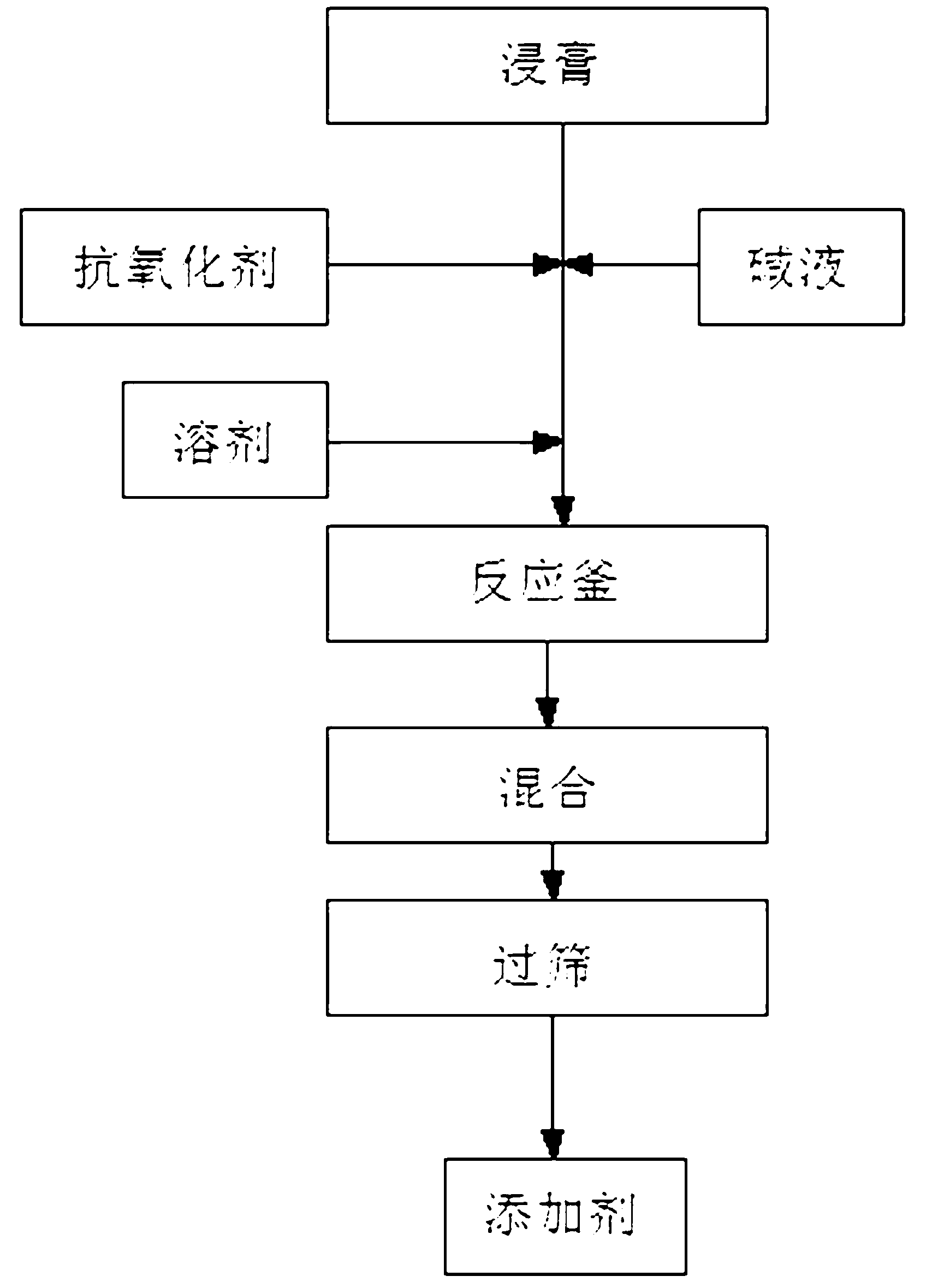

Production process of phytoxanthin feed additive

A feed additive and production process technology, applied in the field of biochemistry, can solve the problems of inconvenient large-scale production, reduced product yield, high production toxicity, and achieve the effects of accelerating saponification speed, low methanol residue, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get the potassium hydroxide of feed grade, be dissolved in water, be made into the potassium hydroxide solution that concentration is 50%;

[0027] Add 27 kilograms of feed grade propylene glycol, 10 kilograms of feed grade ethoxyquinoline and 160 kilograms of potassium hydroxide solution by 270 kilograms of calendula extractum, get calendula extractum, ethoxyquinoline and hydroxide respectively Potassium solution, and then potassium hydroxide solution is added to the calendula extract at a temperature of 40°C to form a reaction solution, the temperature of the reaction solution is controlled below 80°C, and propylene glycol and ethoxyquinoline are sequentially mixed under stirring Add in the reaction solution, heat up to 85°C, and saponify for 55 minutes to obtain a saponified liquid with a temperature of 85°C; add 280 kg of feed grade silicon dioxide powder to 270 kilograms of calendula extract, get the silicon dioxide powder, And adding the obtained silicon dioxide p...

Embodiment 2

[0032] Get the potassium hydroxide of feed grade, be dissolved in water, be made into the potassium hydroxide solution that concentration is 55%;

[0033] Add 27 kilograms of feed grade propylene glycol, 10 kilograms of feed grade ethoxyquinoline and 150 kilograms of potassium hydroxide solution by 270 kilograms of calendula extractum, take calendula extractum, ethoxyquinoline and hydroxide respectively Potassium solution, then potassium hydroxide solution is added to the calendula extract at a temperature of 50°C to form a reaction solution, the temperature of the reaction solution is controlled below 80°C, and propylene glycol and ethoxyquinoline are sequentially mixed under stirring Add in the reaction solution, heat up to 75°C, and saponify for 65 minutes to obtain a saponified liquid with a temperature of 75°C; add 280 kg of feed grade silicon dioxide powder to 270 kilograms of calendula extract, get the silicon dioxide powder, And adding the obtained silicon dioxide powd...

Embodiment 3

[0035] Get the potassium hydroxide of feed grade, be dissolved in water, be made into the potassium hydroxide solution that concentration is 60%;

[0036] Add 27 kilograms of feed grade propylene glycol, 10 kilograms of feed grade ethoxyquinoline and 155 kilograms of potassium hydroxide solution by 270 kilograms of calendula extractum, get calendula extractum, ethoxyquinoline and hydroxide respectively Potassium solution, and then the potassium hydroxide solution is added to the calendula extract at a temperature of 45°C to form a reaction solution, the temperature of the reaction solution is controlled below 80°C, and propylene glycol and ethoxyquinoline are sequentially mixed under the condition of stirring Add in the reaction solution, heat up to 80°C, and saponify for 60 minutes to obtain a saponified liquid with a temperature of 80°C; add 280 kg of feed grade silicon dioxide powder to 270 kilograms of calendula extract, get the silicon dioxide powder, And adding the obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com