Independent shield trolley sleeper and construction method thereof

A shield platform and independent technology, which is applied in the direction of track, track maintenance, movable track, etc., can solve the problems of heavy weight, long time consumption, and many manpower of a single sleeper, so as to reduce the quality of the sleeper, facilitate disassembly and assembly, and improve the quality of the sleeper. Effect of track extension velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The features of the present invention and other relevant features are described in further detail below in conjunction with the accompanying drawings through the embodiments, so as to facilitate the understanding of those skilled in the art:

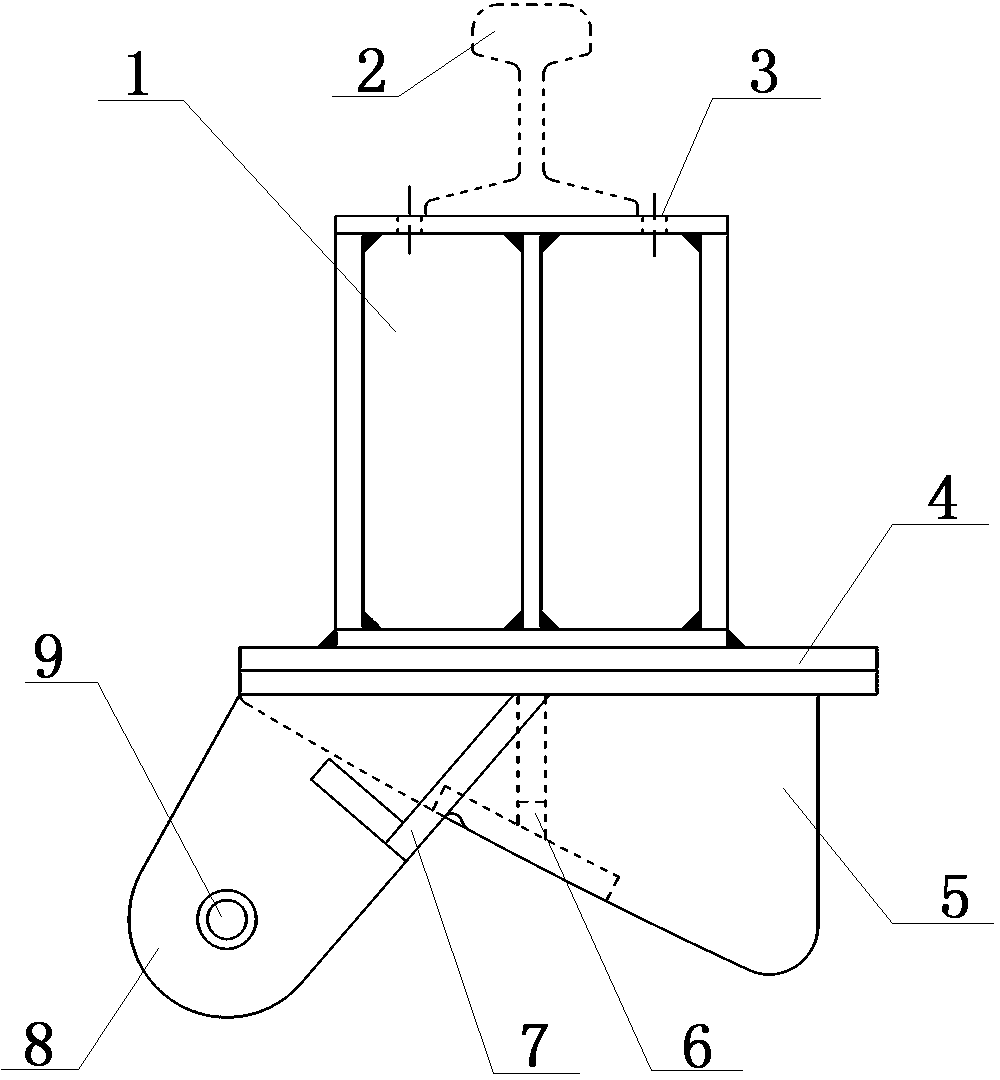

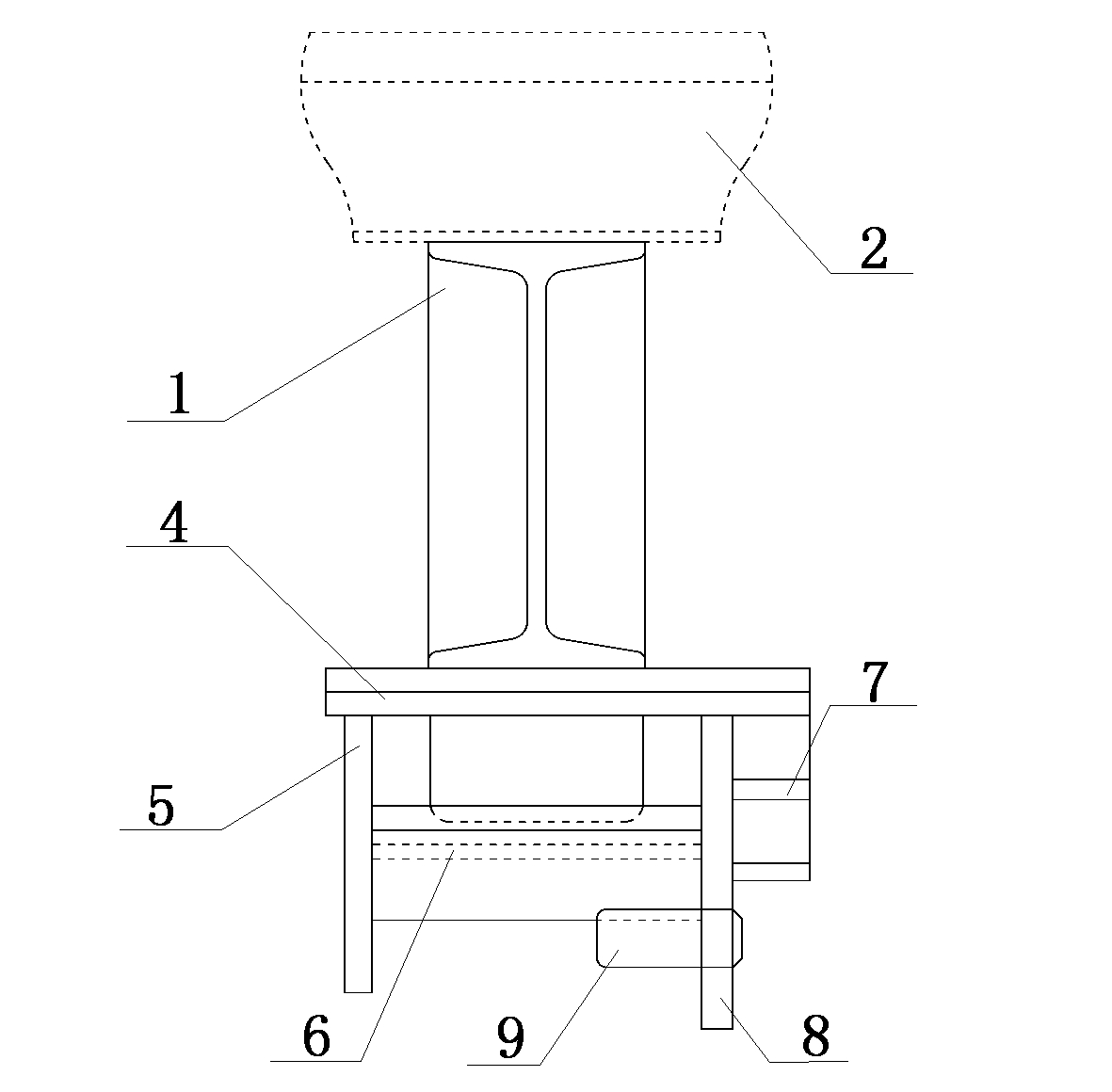

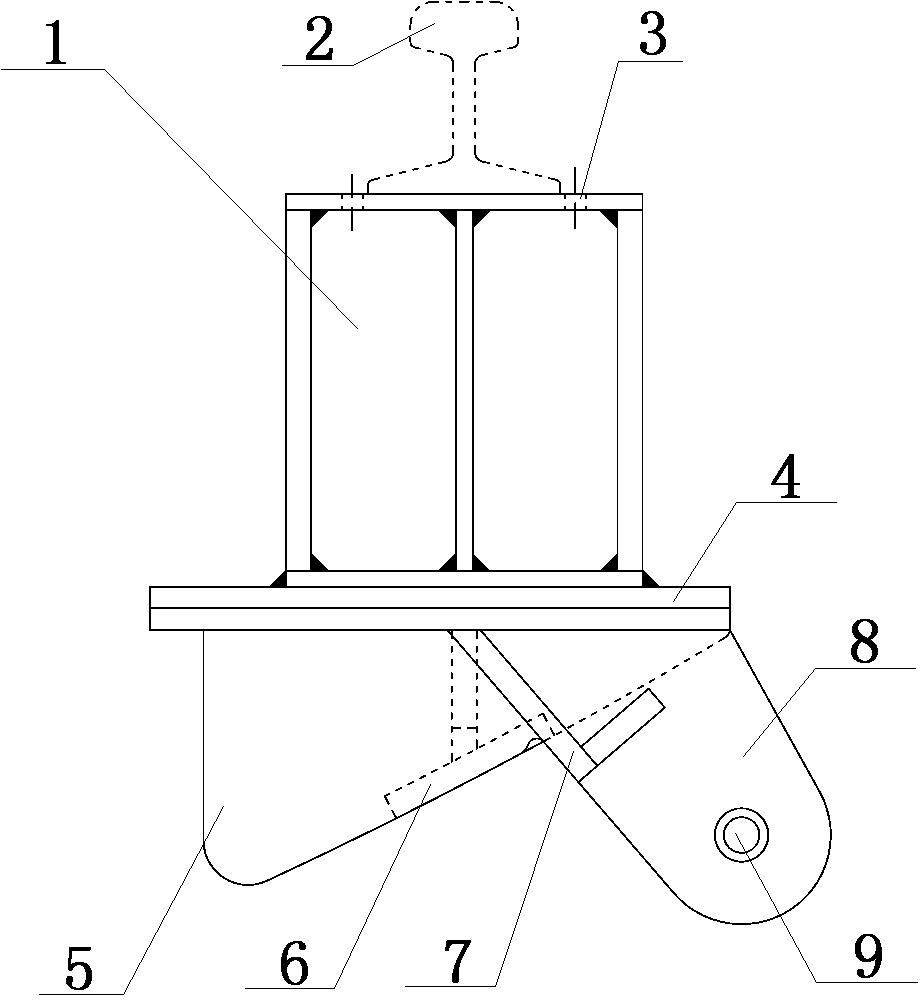

[0022] Such as Figure 1-7 , marks 1-14 in the figure are: I-beam 1, rail 2, limit bolt hole 3, horizontal steel plate 4, vertical steel plate 5, reinforcement rib 6, reinforcement rib 7, limit steel plate 8, limit shaft 9, Bolt holes 10, hand holes 11, sleepers 12, sleepers 13, shield segments 14.

[0023] Example: such as Figure 5 , 6 , 7, this implementation takes the tunnel engineering using the shield method as an example for illustration. During the tunneling construction of the shield machine, the shield trolley behind the shield machine is required to follow the large-gauge sleepers of the shield machine in the tunnel 12 and move forward, and the soil body cut by the shield cutter head and the segments assembled into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com