Rotary flow pickling method and device for removing contaminations in near-wellbore area of oil and gas well

A technology of pickling device and swirling acid, which is used in wellbore/well components, earthwork drilling, cleaning tools, etc., can solve the problem of mud cake removal that affects drilling fluid, limited tangential shearing effect, and difficulty in fully horizontal wells. It can improve the effect of pickling and blockage removal and enhance the diversion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

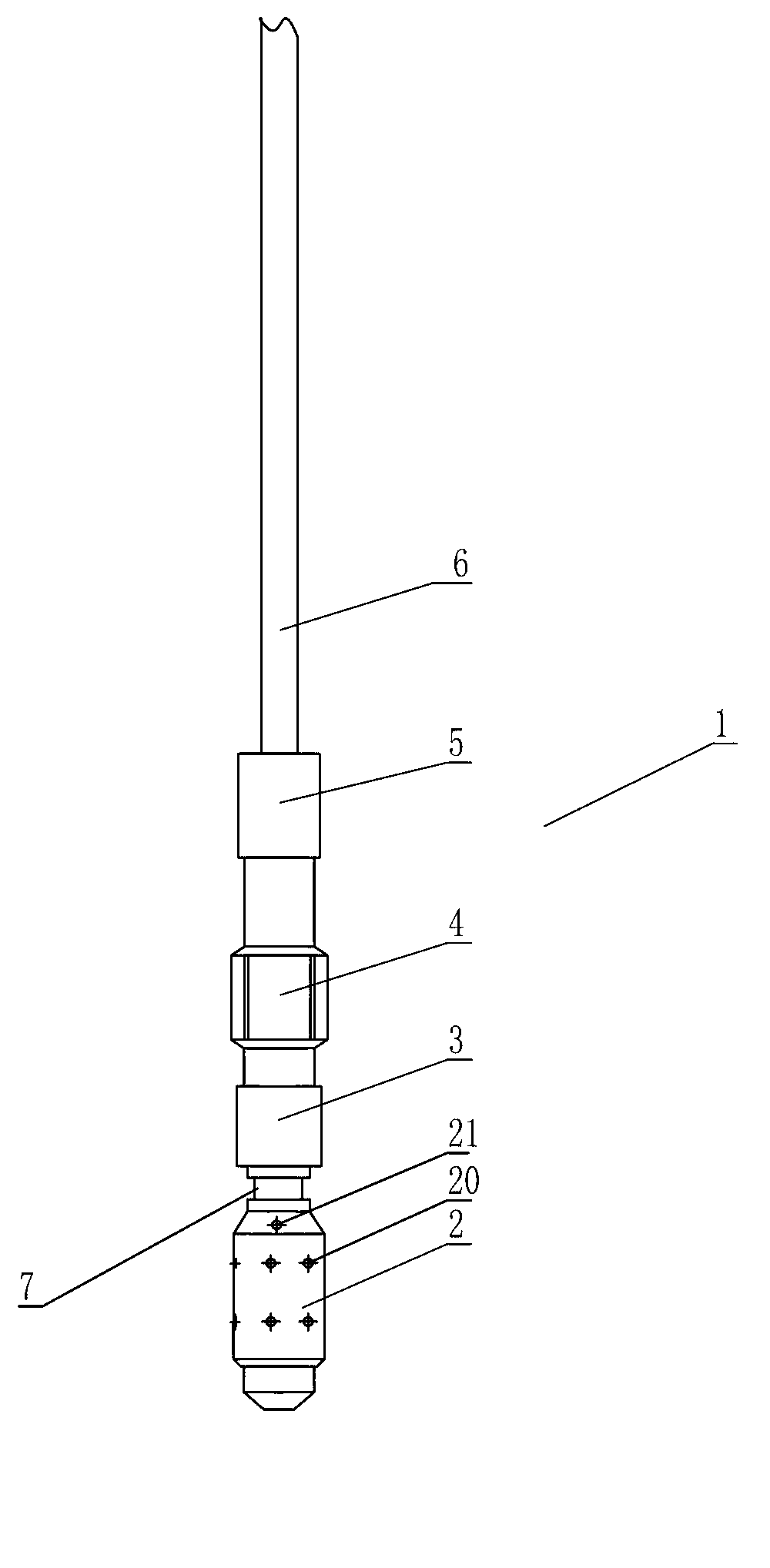

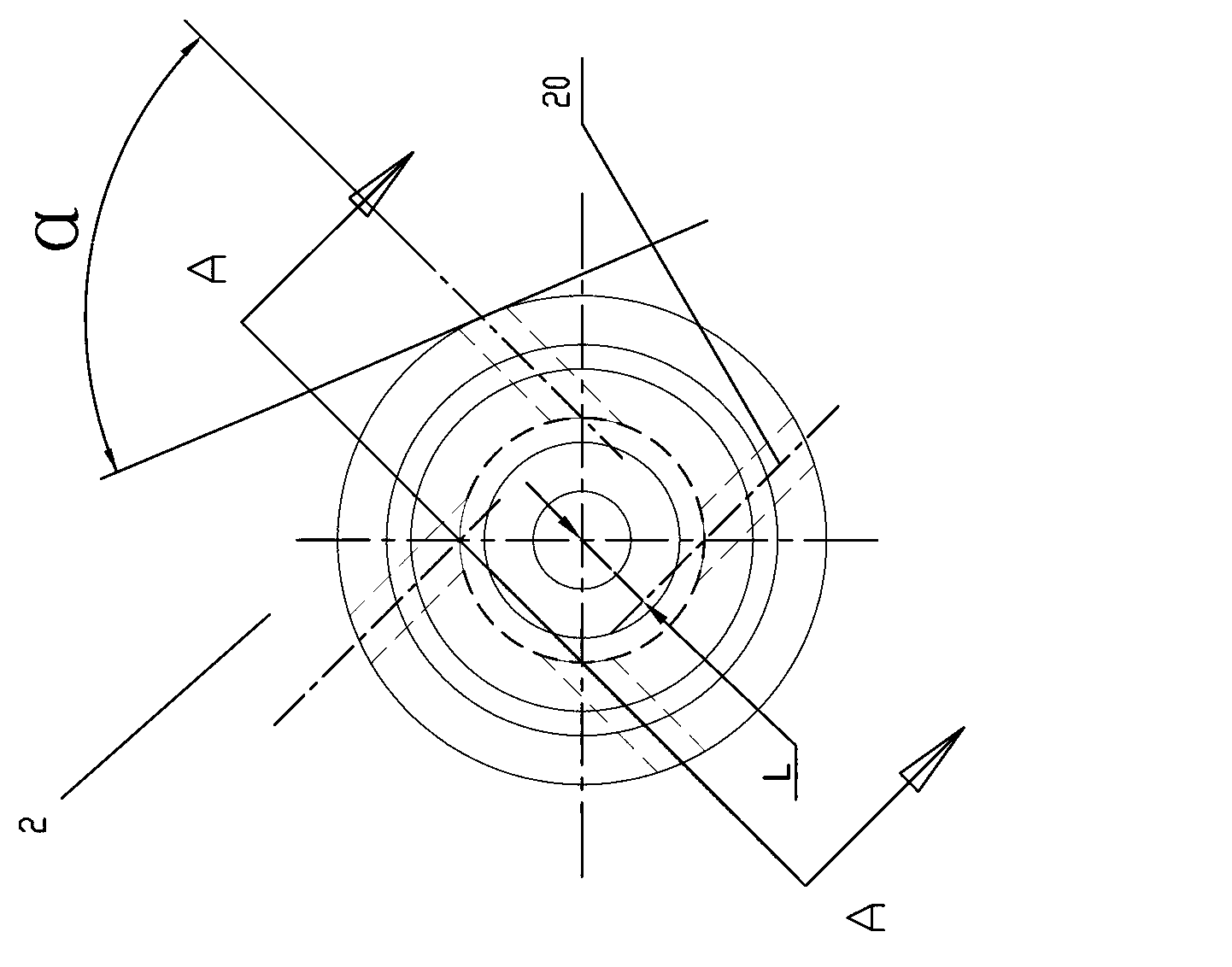

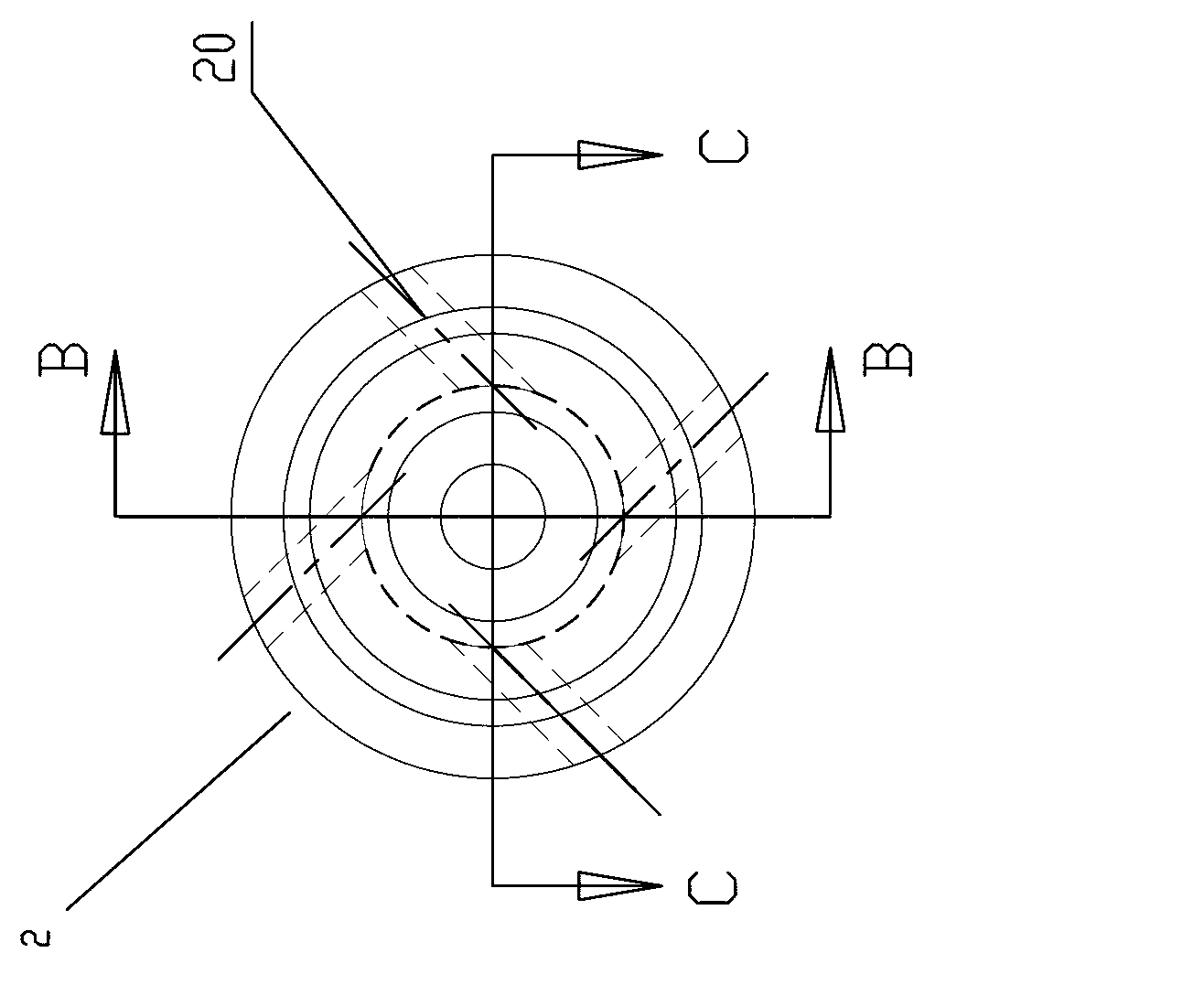

[0042] A swirl pickling device proposed by the present invention has a centralizer, a rotary controller, and a spray gun connected in sequence from top to bottom, and the upper part of the pickling device is fixedly connected to the coiled tubing through a collar; the spray gun can Rotationally connected with the rotary controller, the spray gun is a hollow cylinder, the middle part is a cylinder, the front part and the rear part are respectively formed into flat-section cones with tapering diameters, and the front part of the flat-section cones The front end of the spray gun forms an inner cone hole; the side wall of the middle part of the spray gun is evenly distributed with a plurality of lateral spray holes, and the spray gun can automatically rotate under the action of the fluid; the rear of the spray gun is provided with a backward spray hole to enhance The effect of acid fluid on the wellbore sediment and the mud cake that falls off the well wall.

[0043] The present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com