Test device and method for mechanical characteristics of simulation bottom hole assembly

A bottom drilling tool assembly and test device technology, applied in construction and other directions, can solve problems such as inability to compare tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention relates to a test device and a test method for simulating the mechanical properties of a bottom drilling tool assembly. The present invention is further described in conjunction with the accompanying drawings and specific implementation methods.

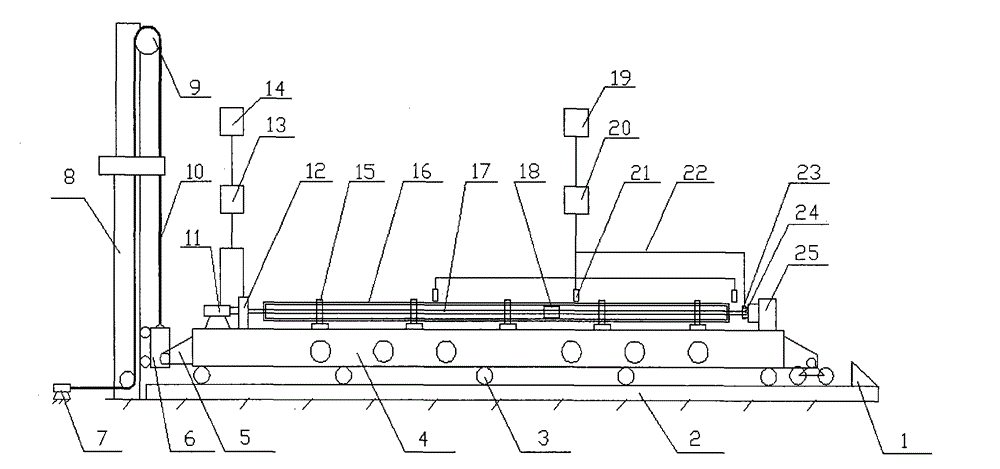

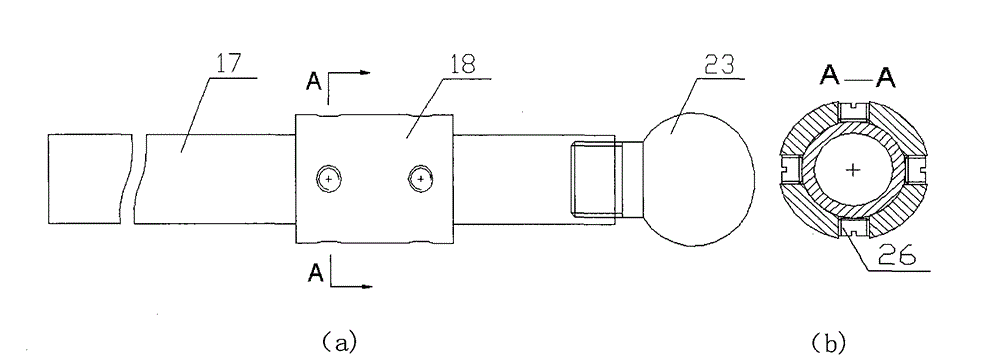

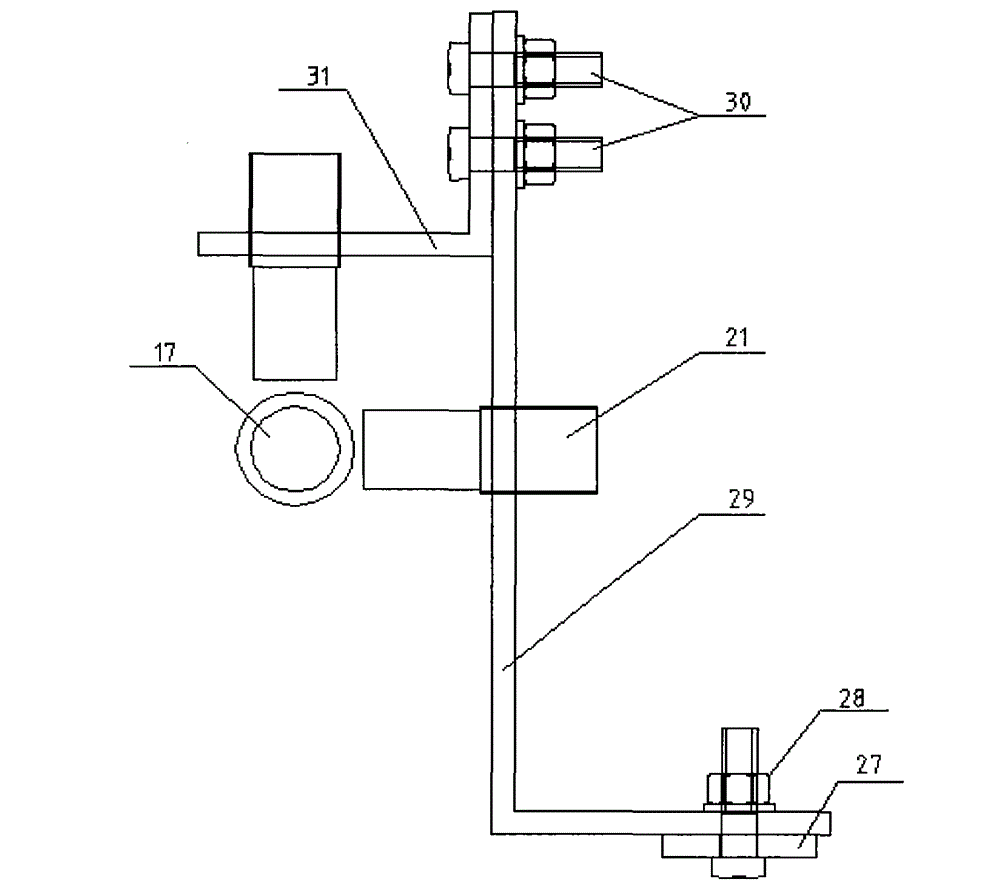

[0029] Such as figure 1 As shown, the test device provided by the present invention includes a simulated bottom hole assembly system, a drive system, a control system, a measurement system, and a lifting system; the simulated bottom hole assembly system consists of a simulated wellbore 16, a simulated drill collar 17, a simulated stabilizer 18, The simulation drill bit 24 is composed; the driving system is composed of an electric motor 11 and a hydraulic motor 12; the control system is composed of a measuring and controlling instrument 13 and an industrial computer 14; the measuring system is composed of a computer 19, a signal acquisition module 20, an eddy current displacement sensor 21, a signal cable 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com