Method for building urban underground tunnel shield cutter repairing space with preset reinforcing pile groups

A technology for underground tunnels and shield cutterheads, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve the problems of high cost, long construction period, and huge cost, so as to reduce project investment, shorten repair time, and ensure normal construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

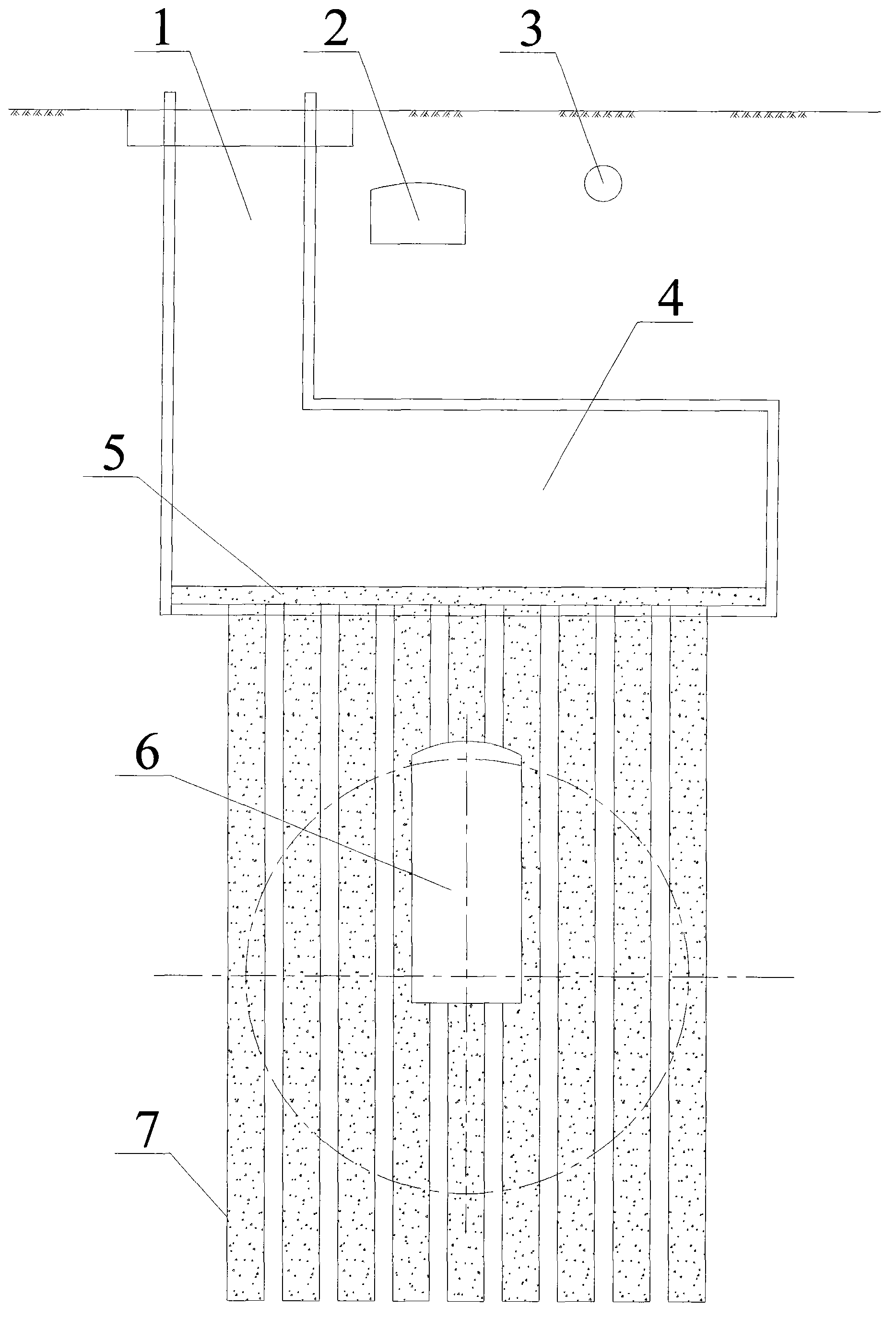

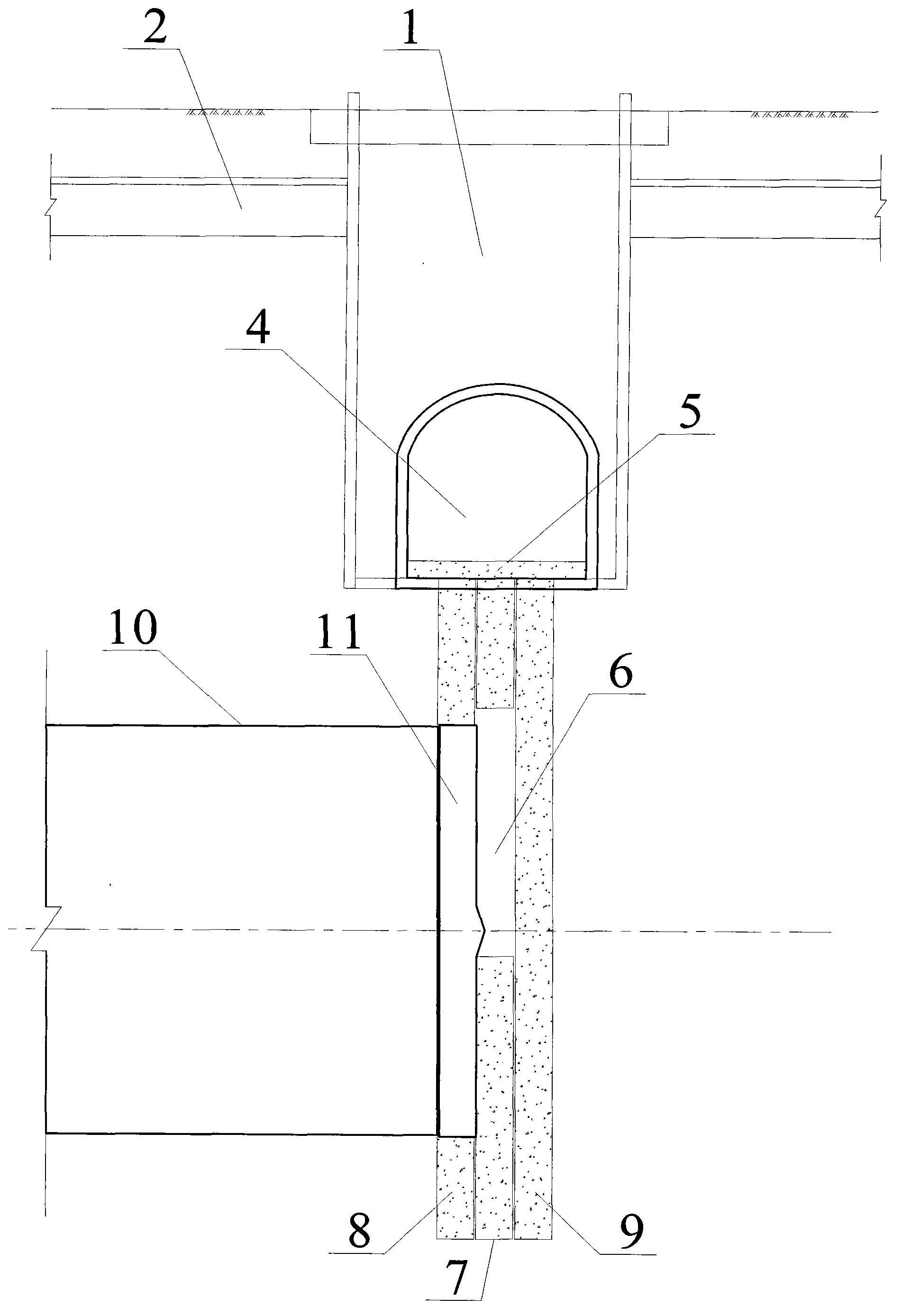

[0021] The present invention is a method for establishing a repair space for the shield cutter head of an urban underground tunnel by presetting reinforcement pile groups. The method can avoid buildings, important traffic arteries, important underground pipelines and underground structures above the ground where the shield cutter head is excavated. In the case of direct excavation of the shaft, the repair space for the shield cutter head of the urban underground tunnel is established by using the preset reinforcement pile group method, which provides the possibility to repair the shield cutter head, shortens the repair time of the cutter head, and ensures the normal operation of the shield machine. construction.

[0022] First of all, it is assumed that the excavation diameter of the underground tunnel and the design direction of the tunnel’s driving axis have been determined, the underground tunnel is located below the downtown area of the city and the top elevation of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com