High-performance cold patch asphalt mixture and preparation method thereof

A technology for cold patching asphalt and mixtures, which is applied to building thermal insulation materials, building components, buildings, etc., can solve the problems of shortening service life, poor early strength and low strength of cold patching asphalt mixtures, and achieves low mass loss rate, Good low temperature cracking resistance, not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

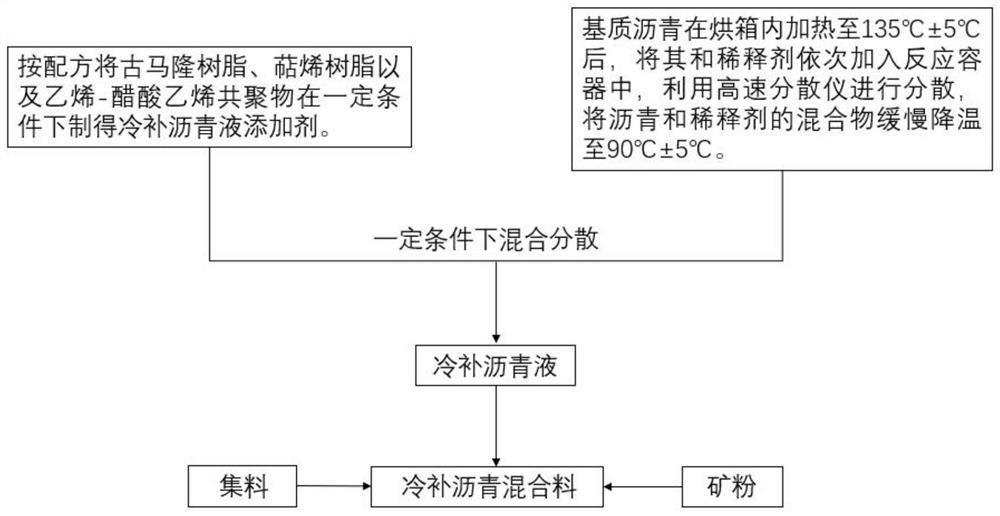

[0064] Such as figure 1 Shown, the present invention also provides a kind of preparation method of high-performance cold patch asphalt mixture, comprises the following steps:

[0065] Step S1, selecting and weighing aggregates, mineral powder, and cold-patched asphalt liquid with different particle sizes according to the mass parts, from 100 parts of aggregate, 2.5-3.5 parts of mineral powder, and 4.5-5.5 parts of cold-patched asphalt liquid;

[0066] Step S2, put the weighed aggregate and mineral powder in an oven at 85°C for 3-4 hours; put the weighed cold asphalt liquid in an oven at 70°C for 1 hour; keep the mixing pot at 80°C ℃; aggregate and mineral powder heat preservation is to dry the water in them, and cold-patch asphalt liquid heat preservation is to keep it in a flowing state for easy mixing; aggregate and mineral powder are solid, and the temperature rises slowly, so as to fully dry the water and make it It is heated evenly, with a high temperature and a long tim...

Embodiment 1

[0078] Step S1, weighing aggregates, mineral powder, and cold patched asphalt liquid according to the mass parts as 100 parts of aggregate, 3 parts of mineral powder, and 5 parts of cold patched asphalt liquid;

[0079] Step S2, put the weighed aggregate and mineral powder in an oven at 85°C for 3-4 hours; put the weighed cold asphalt liquid in an oven at 70°C for 1 hour; keep the mixing pot at 80°C ℃;

[0080] Step S3, first add the heat-preserved aggregate into the heat-preserved mixing pot, and stir for 90 seconds; then add the heat-preserved cold patching asphalt liquid into the stirring pot, and stir for 90 seconds; finally, add the heat-preserved mineral powder into the stirring pot, Stir for 90s to obtain the cold-patch asphalt mixture;

[0081] Step S4, bagging and sealing the cold-patch asphalt mixture prepared in step S3 for storage.

[0082] Wherein the preparation method of the cold asphalt liquid is as follows:

[0083] Step S11, select and weigh the coumarone ...

Embodiment 2

[0088] On the basis of Example 1, the components of the cold-patched asphalt mixture are adjusted to be composed of 100 parts of aggregate, 2.5 parts of mineral powder, and 5 parts of cold-patched asphalt liquid in parts by mass; the components of cold-patched asphalt liquid are adjusted to The mass ratio of asphalt, diluent and additive is 100:22:7; other parameters remain unchanged to prepare cold patch asphalt liquid and cold patch asphalt mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| residual stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com